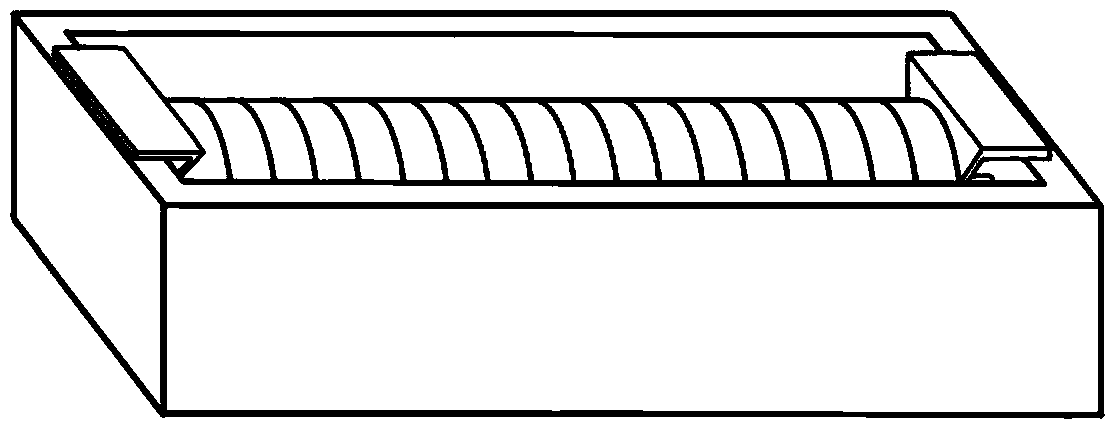

Small-sized surface mounting magnetic shielding power inductor and preparation method of small-sized surface mounting magnetic shielding power inductor

A surface mount, power inductance technology, applied in the field of inductors, can solve the problems of large volume, small inductance value, small rated current value, etc., and achieve the effect of small inductance, strong anti-saturation magnetization ability, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] NiZn ferrite material preparation method of the present invention, comprises the following steps:

[0037] 1. Formulation: 49.0~50.8mol% Fe is used 2 o 3 , 28.0~30.0mol%ZnO, 6.0~8.0mol%CuO, the balance being NiO; 2. One-time ball milling: mix the above powders evenly in the ball mill for 2-4 hours; The ball mill is dried and pre-fired in a furnace at 850-950°C for 2-4 hours; 4. Doping: Add the following dopant to the powder obtained in step 3 by weight ratio: 0.10-0.25wt% Bi 2 o 3 , 0.065~0.125wt%MoO 3 , 0.02~0.075wt%CaCO 3 5. Secondary ball milling: mill the powder obtained in step 4 in a ball mill for 3 to 6 hours; 6. Molding: add 12 to 16 wt% organic binder to the powder obtained in step 5 by weight, mix evenly, After granulation, press the granular powder into a blank on a press; 7. Sintering: put the green body obtained in step 6 into a sintering furnace for sintering, and keep it warm at 1050-1120° C. for 3-5 hours.

[0038] Second, power inductors

[0039]...

Embodiment 3~8

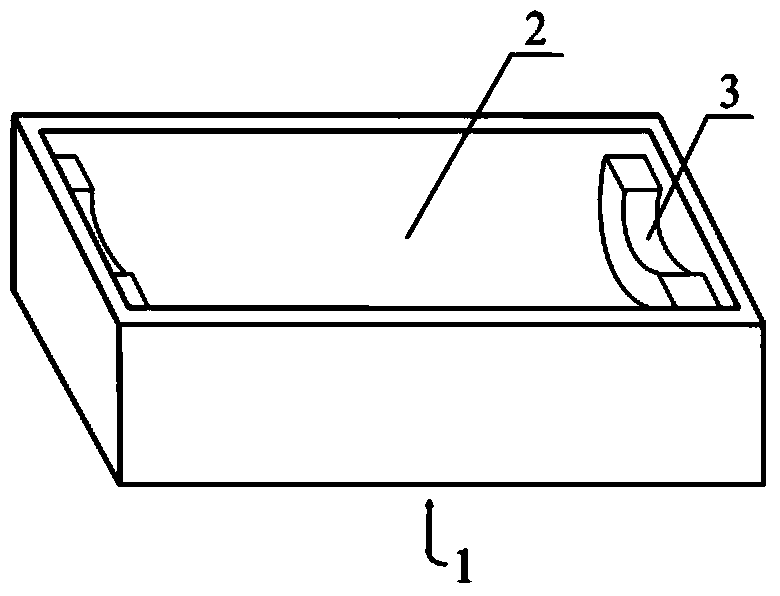

[0062] 1. Shell core

[0063] 1. Formula

[0064] Component Fe 2 o 3 The contents of , ZnO and CuO are respectively 49.4, 29.0 and 6.5mol%, and the balance is NiO;

[0065] 2. One ball milling

[0066] Mix the above powders evenly in a ball mill for 3 hours;

[0067] 3. Pre-burning

[0068] Dry the ball mill material obtained in step 2, and pre-fire it in a furnace at 930°C for 3 hours;

[0069] 4. Doping

[0070] Add the following dopant by weight ratio to the powder obtained in step 3: 0.15wt%Bi 2 o 3 , 0.080wt%MoO 3 , 0.040wt%CaCO 3 ;

[0071] 5. Secondary ball milling

[0072] The powder obtained in step 4 was ball milled in a ball mill for 4 hours;

[0073] 6. Forming

[0074] Add 15wt% organic binder to the powder obtained in step 5 by weight, mix evenly, and granulate, then sieve with a 40-mesh sieve, and get the powder granules whose particle size is between 40 mesh and 200 mesh. Add 0.5% zinc stearate to the selected powder and pellets, use a shell magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com