Etching method to enhance web growth

A network and substrate technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the performance impact of SiC devices, achieve the effect of increasing the film growth area and shortening the epitaxy time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

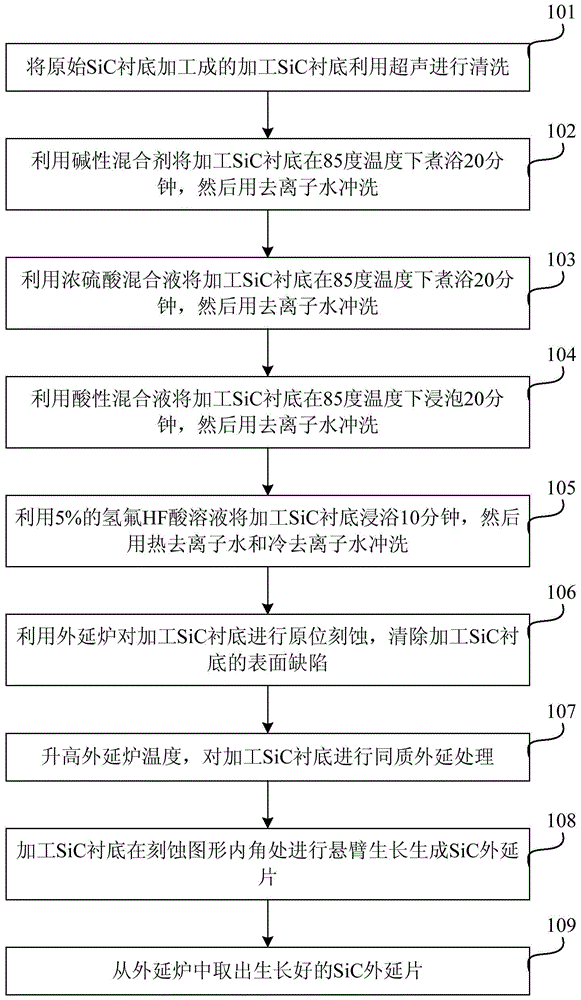

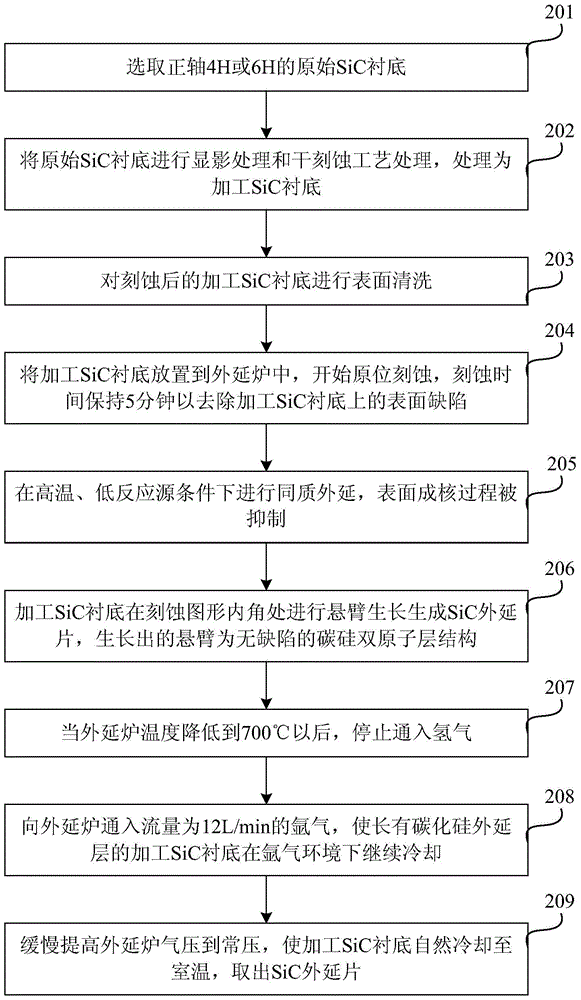

[0027] figure 1 It is a flow chart of embodiment 1 of the etching method for improving Web Growth in the present invention, as shown in the figure, this embodiment specifically includes:

[0028] Step 101, cleaning the processed SiC substrate processed by using the original silicon carbide SiC substrate with positive axis 4H or 6H by ultrasonic;

[0029] Step 102, using an alkaline mixture to boil the processed SiC substrate at a temperature of 85 degrees for 20 minutes, and then rinse it with deionized water;

[0030] Step 103, soaking the processed SiC substrate in a bath at 85 degrees for 20 minutes with a concentrated sulfuric acid mixture, and then rinsing with deionized water;

[0031] Step 104, soak the processed SiC substrate at a temperature of 85 degrees for 20 minutes with an acidic mixed solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com