Method for Detecting Oxygen Leakage in Reaction Chamber of Annealing Equipment

A technology of annealing equipment and reaction chamber, which is used in the application of electrical devices to test fluid tightness, semiconductor/solid-state device testing/measurement, etc., can solve the problems of semiconductor device device failure, oxygen leakage, cross-contamination of other machines, etc. Short circuit, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

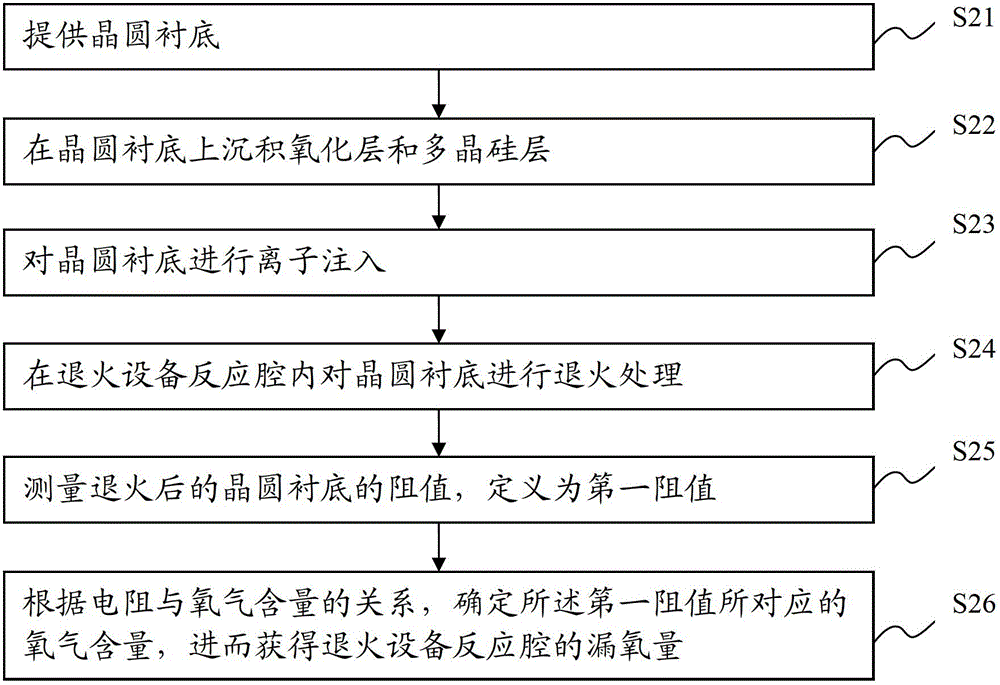

[0037] The introduction of oxygen can greatly increase the diffusion speed of impurity ions along the grain boundary, so when the oxygen content increases, the activation rate of impurities can be increased, and the increase of carriers can cause the decrease of resistance.

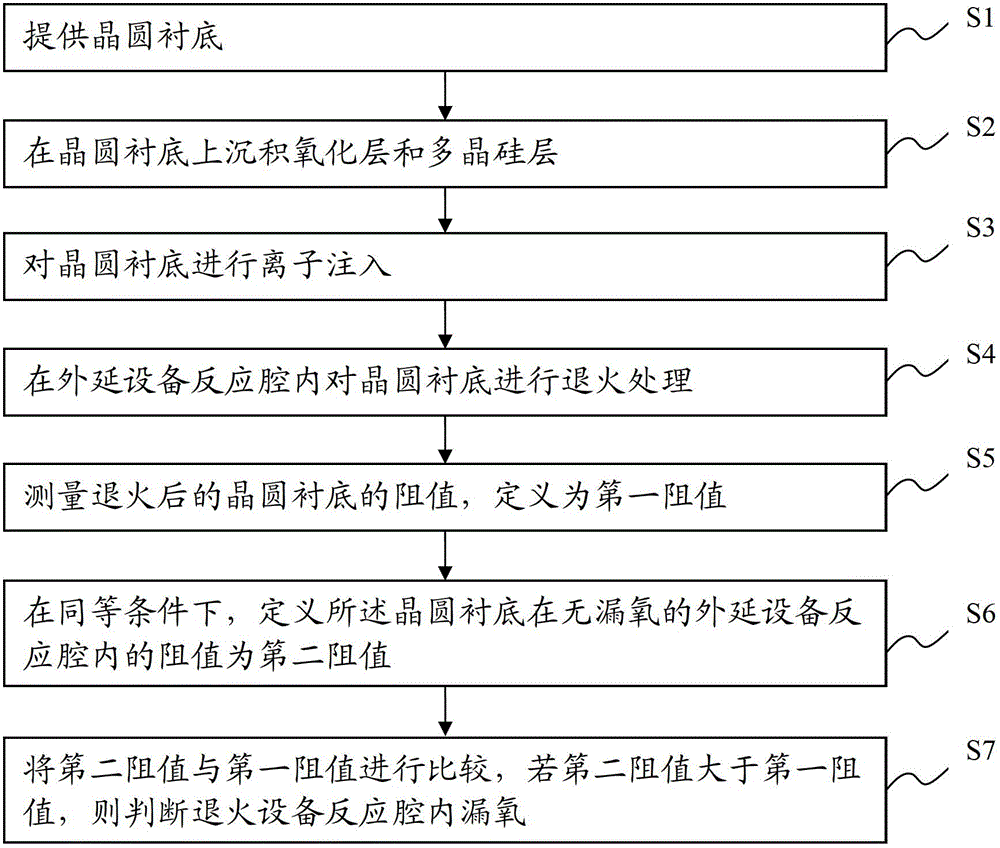

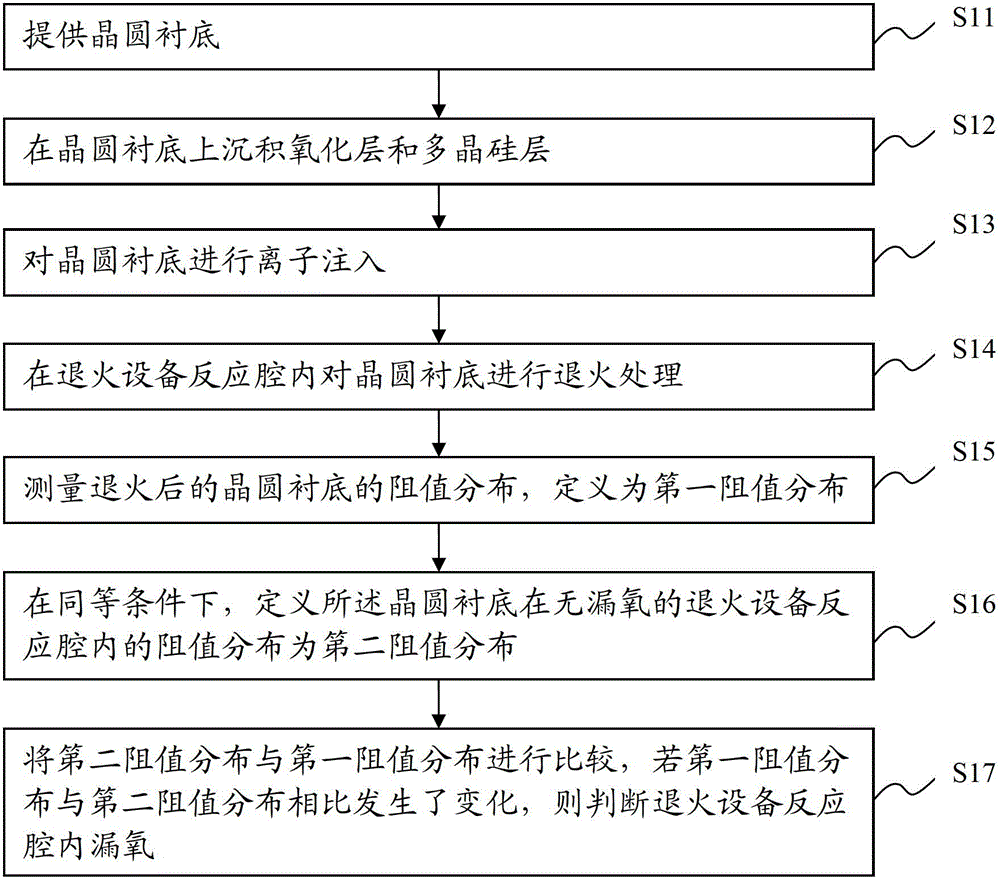

[0038] Based on the above principles, the present invention detects whether there is oxygen leakage in the reaction chamber, the amount of oxygen leakage, and the location of oxygen leakage by depositing an oxide layer and a polysilicon layer on the wafer substrate, ion implantation, and then observing the resistance value after annealing.

[0039] Referring to Table 1, using the same wafer substrate, under the same ion implantation conditions and annealing temperature, different oxygen contents were introduced into the reaction chamber of the annealing equipment to observe the changes of the wafer substrate. It can be seen from Table 1 that the resistance value of the wafer substrate is very high when no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com