Pole piece and laminated electrical core body for lithium ion battery

A lithium-ion battery and pole piece technology, applied in battery electrodes, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as short circuit and arc pole piece contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

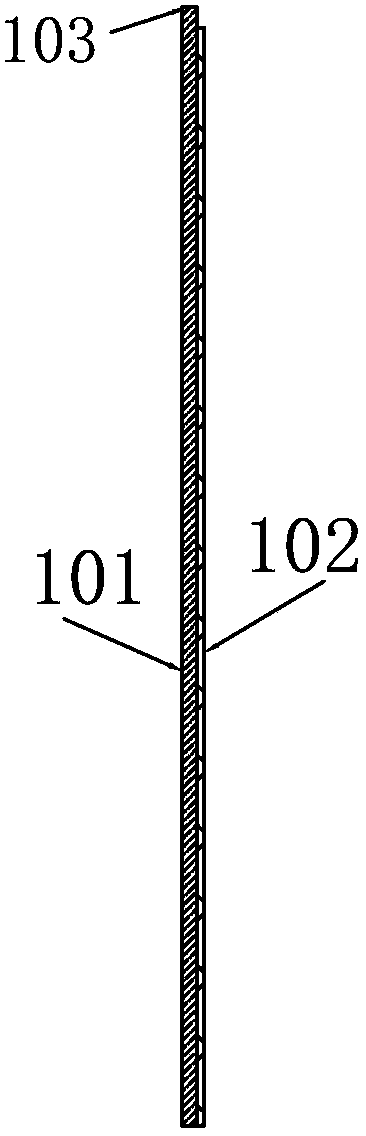

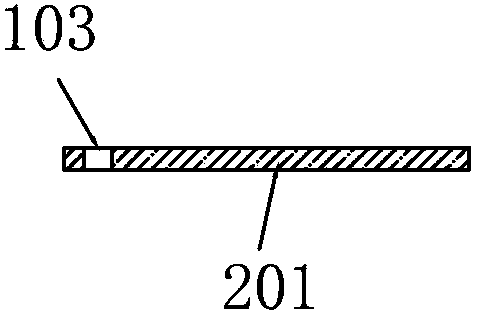

[0031] see figure 1 , 2 As shown, a pole piece for a lithium ion battery provided in this embodiment mainly includes: a metal current collector 101, an active material layer 102 is coated on the surface of the metal current collector 101, and the metal current collector 101 also extends There is a tab welding part 103, and the active material layer 102 is not coated on the tab welding part 103 so that the metal substrate is exposed. In this embodiment, the end part extending from the tab welding part 103 is the first pole. end 201, the cross-section of the first end 201 of the metal current collector 101 ( figure 2 The area marked with a slash) is coated with an insulating silicone layer.

[0032] It can be seen from the above that by applying the technical solution of this embodiment, since the cross-section of the end 201 extending from the tab welding portion 103 on the pole piece is also coated with an insulating silica gel layer, the tab of the above structure is used ...

Embodiment 2

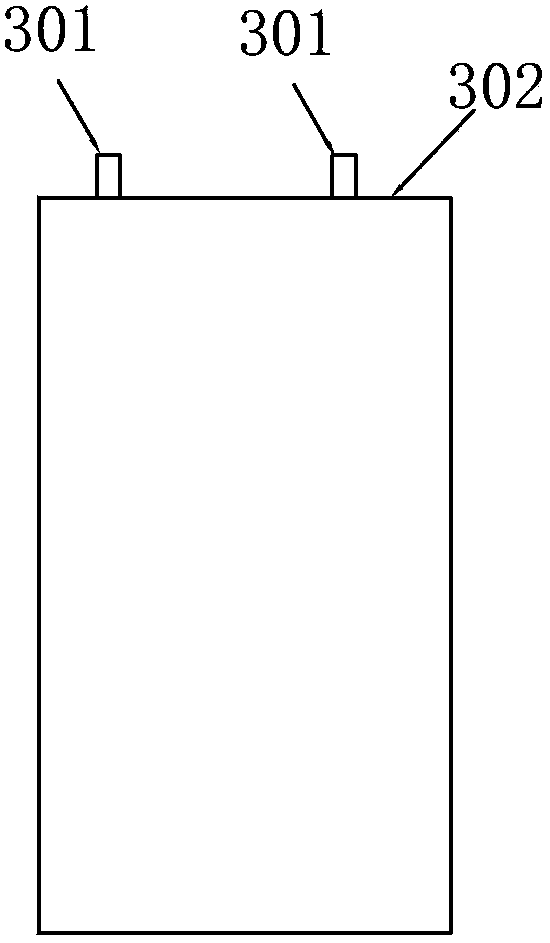

[0037] see image 3 As shown, this embodiment provides a laminated lithium-ion battery core body, which mainly includes positive plates stacked up and down together (not shown in the figure, its structure can be, but not limited to, as in Example 1 shown), the negative electrode sheet (not shown in the figure, its structure can be but not limited to that shown in Example 1) and the separator, and there is a separator between any adjacent positive electrode sheet and negative electrode sheet.

[0038] At least one width end of each positive electrode sheet and negative electrode sheet is respectively extended with a protruding tab welding part 301 from the metal current collector, and the surface of the tab welding part 301 is not coated with an active material layer, so that the metal collector Fluid exposed.

[0039] The laminated lithium-ion cell body can be made by "Z"-shaped laminations or bag-type laminations or other laminations.

[0040] After the lamination is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com