Ganoderma lucidum-based processing method and production method for ganoderma lucidum-based product

A production method, Ganoderma lucidum technology, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

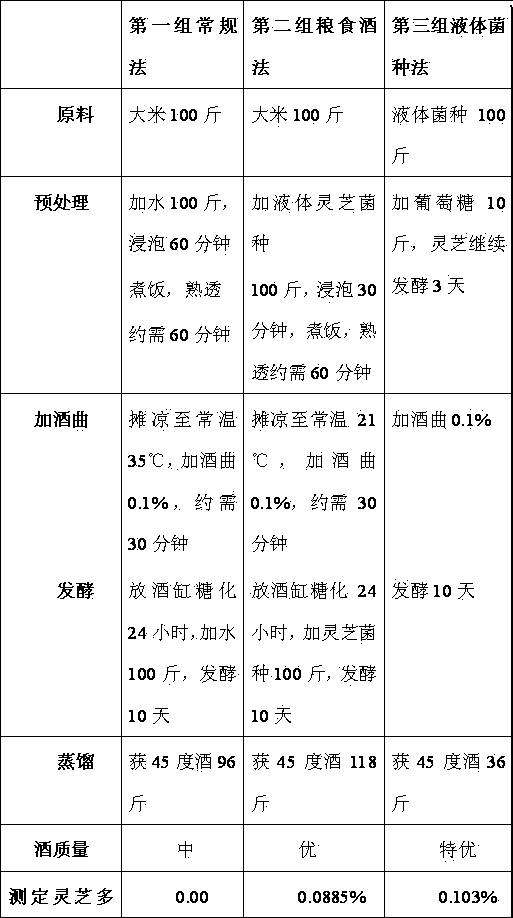

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the production method of Ganoderma lucidum feed

[0033] The conventional feed production process includes: raw material pretreatment (receiving, primary cleaning), crushing, batching, mixing, product forming (cooling, crushing and grading) and production (weighing, packaging) and other processes.

[0034] The Ganoderma lucidum feed production process is based on the conventional feed production process, adding a moderate fermentation process of Ganoderma lucidum: all feed materials are mixed evenly, the water content is adjusted to (30-70)%, and the ganoderma strains are added to account for the total mass of the mixed raw materials ( 1-20)% (best 5%), normal temperature fermentation (1-10) days (best 2 days), product moisture control to: (8-50)% (best 12%), packaged.

[0035] The conventional process of product molding includes: powder, granule, sheet, pellet, etc., and the physical processing process can be copied in the present invention. The form o...

Embodiment 2

[0046] Embodiment 2, the production method of Ganoderma lucidum animal

[0047] On the basis of the conventional breeding process, add the moderate fermentation process of Ganoderma lucidum to the feeding ration: adjust the water content of the full-price ration for feeding animals to (30-70)%, add the ganoderma lucidum strain to (1% of the total mass of the mixed raw materials) -20)% (best 5%), after normal temperature fermentation (1-10) days (best 2 days), product moisture control (8-50)% (best 12%), according to the standard of animal nutrition requirements Regular feeding. Regulating the water content of ganoderma lucidum feed is for preservation. If it is ready-to-use, it can be used directly without regulating the water content.

[0048] Another way to achieve the same effect is to use Ganoderma lucidum feed. Generally, ganoderma strains are added to account for (1-50)% (best 5%) of the total mass of the mixed feed. If it is a full-price ganoderma feed, it can also ...

Embodiment 3

[0055] Embodiment 3, Ganoderma lucidum meat product production method

[0056] Conventional meat production processes are mainly: slaughtering, segmentation, preservation and deep processing.

[0057] The production process of Ganoderma lucidum meat products is based on the conventional process, after slaughtering and dividing, soak it in liquid Ganoderma lucidum strains for moderate fermentation of Ganoderma lucidum, usually at (15-25)°C (optimally 19°C) , Soak (1-100) hours (best 24 hours), Ganoderma lucidum products have been obtained. After fermentation, in order to facilitate the preservation of the product, the water content of the product can be adjusted to (15-75)% (optimally 55%). The best effect of the present invention is to use Ganoderma lucidum feed to breed Ganoderma lucidum animals, and then produce Ganoderma lucidum animal meat products, that is, carry out triple Ganodermaization production, and finally adopt vacuum packaging.

[0058] The following takes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com