Platinum nanometer composite catalyst, preparation and application thereof

A composite catalyst, platinum nanotechnology, applied in the preparation of amino compounds, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

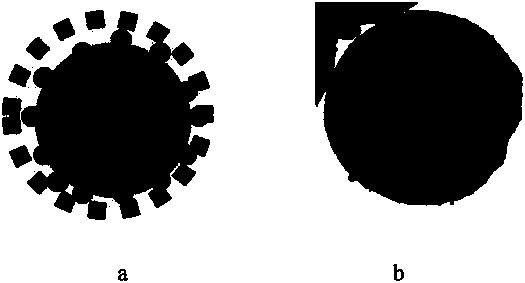

[0012] Preparation of SiO wrapped in mesoporous zirconia shell 2 / Pt / ZrO 2 The composite nano-catalyst of structure, comprises the following steps:

[0013] (1) Preparation of SiO 2 Beads: a mixed solution of tetraethylorthosilicate (6.2mL), 6.5mL ammonia water (28wt%), absolute ethanol (100mL) and deionized water (7mL), stirred at room temperature for 15 hours. Wash twice with deionized water and ethanol respectively to obtain SiO with a diameter of 200-300nm 2 small ball.

[0014] (2) Preparation of Pt nanoparticles: polyvinylpyrrolidone (0.05g), K 2 PtCl 6 (0.068g), deionized water (20mL) mixed in a 25mL three-necked bottle, H 2 By reducing the mixture, Pt nanoparticles can be prepared.

[0015] (3) Amino surface functionalized SiO 2 Small balls: SiO 2 Disperse the pellets (1-3g) into 100mL of isopropanol, then add 3-triethoxysilyl-1-propanamine (1-3mL), heat and stir at 60-80°C for 2 hours. Amine-functionalized SiO 2 small ball.

[0016] (4) Self-assembled SiO ...

Embodiment 2

[0019] Preparation of SiO 2 / Pt core-shell nanocatalysts.

[0020] The preparation steps are the same as steps (1)-(4) in Example 1

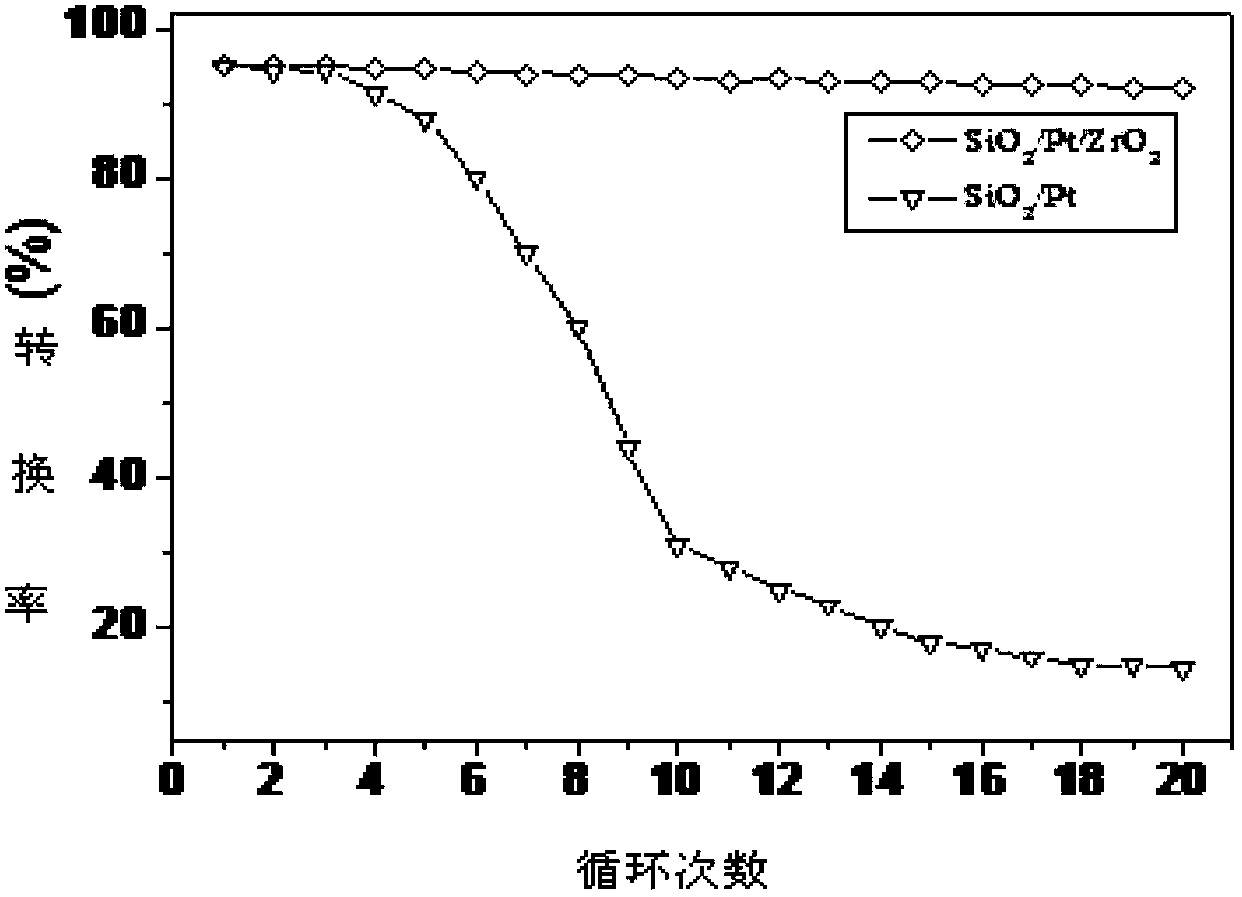

[0021] Depend on figure 2 It can be concluded that the SiO wrapped in the mesoporous zirconia shell 2 / Pt / ZrO 2 After the composite catalyst was applied for 20 cycles, the conversion rate decreased slightly and basically remained unchanged. Catalyst SiO without mesoporous zirconia shell encapsulation 2 After 3 reaction cycles of / Pt application, the reaction conversion rate decreased rapidly, which may be due to the transfer of Pt nanoparticles from the carrier SiO 2 Caused by the shedding of the ball surface. Therefore, the SiO wrapped in the mesoporous zirconia shell prepared by the method of the present invention 2 / Pt / ZrO 2 The catalyst can be recycled many times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com