Abrasive recovery device in abrasive water jet scale removal system

A technology of abrasive water jet and descaling system, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve the problem of low service life of pre-mixed wearing parts, no abrasive recovery device, and inability to operate continuously and other problems, to achieve the effect of reducing production cost, high abrasive classification rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

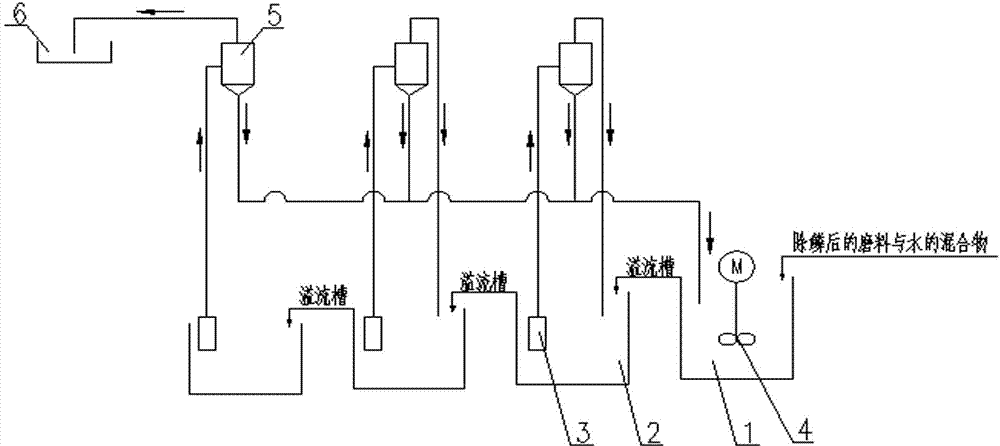

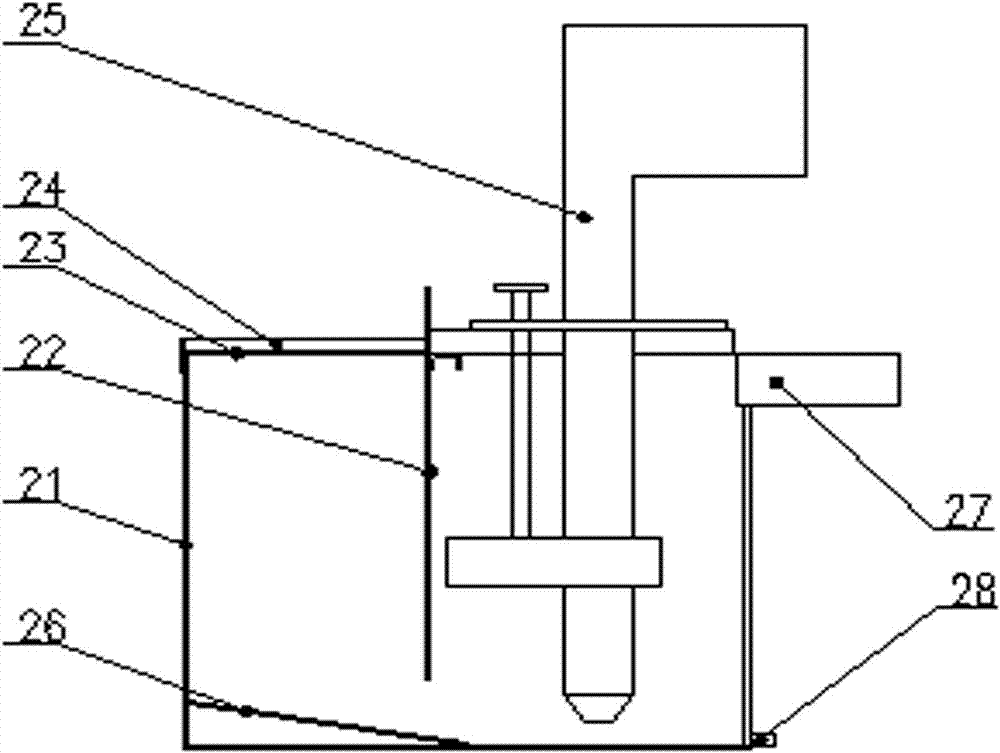

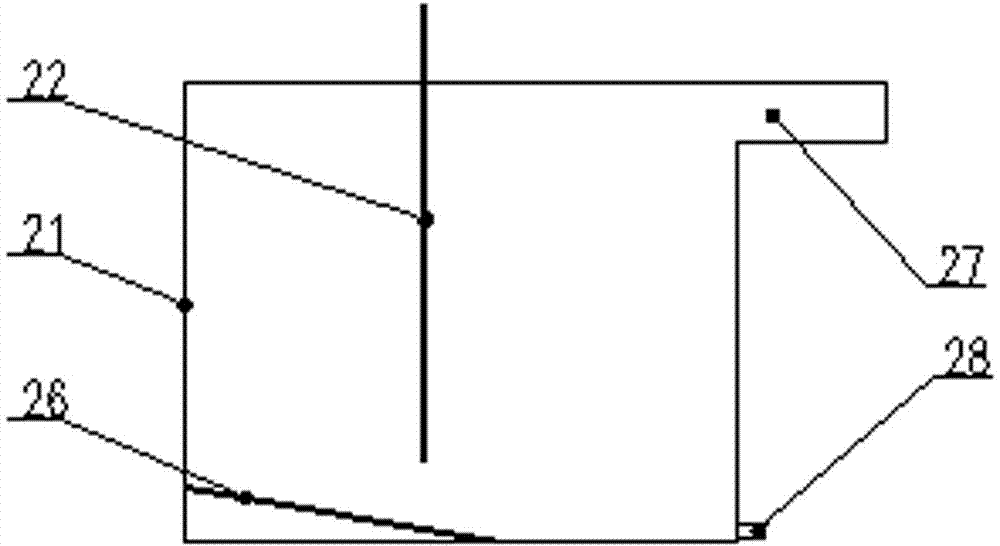

[0017] like Figure 1 to Figure 3 As shown, the abrasive recovery device in the abrasive water jet descaling system provided by the present invention includes a mixing bucket 1 and a recovery bucket 2, the recovery bucket 2 has three stages, and there is a vertical slurry pump 3 in the recovery bucket 2 of each stage , each recovery bucket 2 is correspondingly equipped with a cyclone separator 5 , and the outlet of the vertical slurry pump 3 is connected with the feed port of the corresponding cyclone separator 5 . The overflow ports of the first and second stage cyclone separators 5 return to the barrel body of the present stage, and the overflow ports of the third stage cyclone separators 5 lead to the sediment pool 6 . The abrasive liquid outlet at the bottom of each cyclone separator 5 is connected to the mixing tank 1 through a confluence pipe, and the abrasive liquid with a larger particle size is introduced into the mixing tank 1 again. A stirrer 4 is arranged in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com