High-voltage electric operating robot control system and method based on virtual reality technology

A working robot, high-voltage live technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of inability to guarantee collisions and other unexpected situations, cannot fully cover all details, and the control process is cumbersome, etc. The interface is friendly, the visualization is improved, and the operation process is simplified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

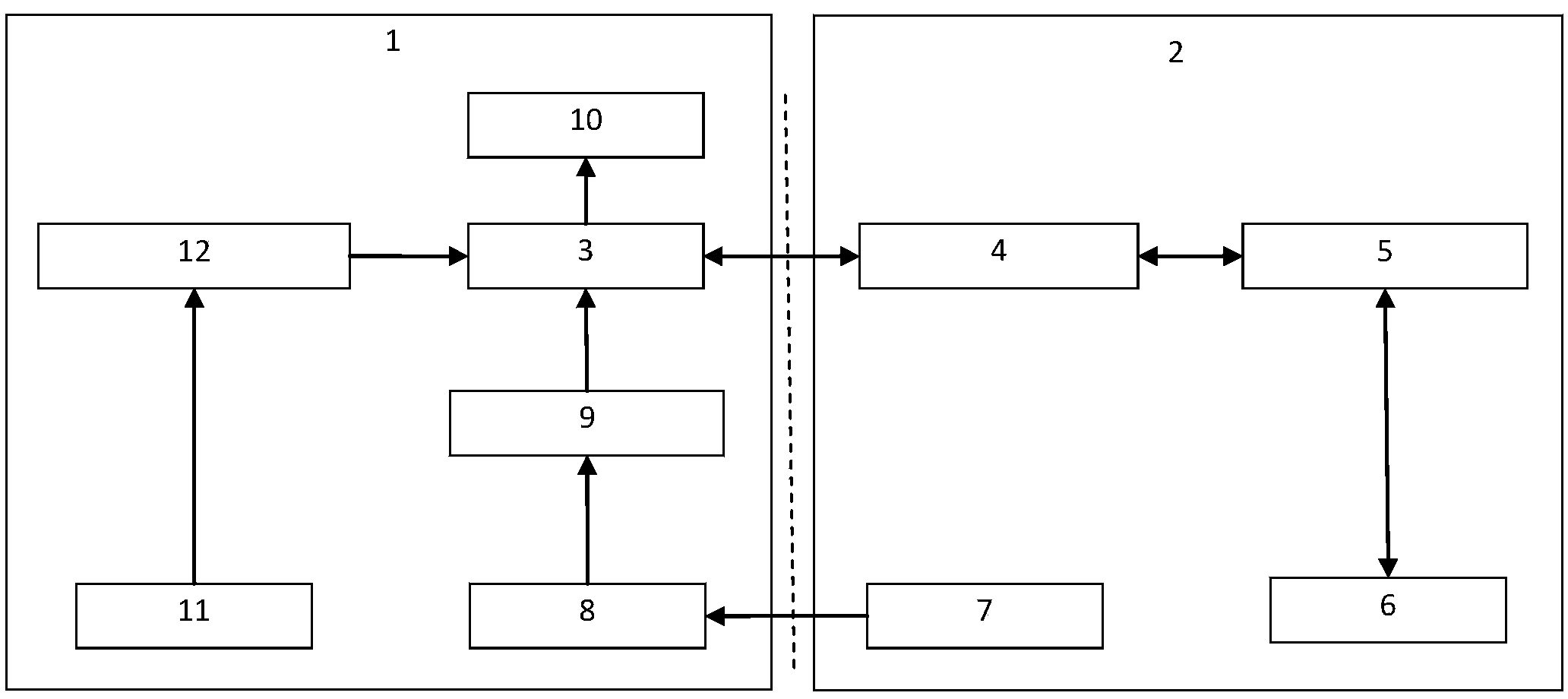

[0047] like figure 1 As shown, the high-voltage live working robot control system based on virtual reality technology includes a remote control terminal 1 and a working terminal 2. The remote control terminal 1 is installed in the ground operating room, and the working terminal 2 is installed in the insulating bucket above the hydraulic lifting platform. ;

[0048] Described remote control terminal comprises main hand 11, main hand information acquisition unit 12, main computer 3, image processing computer 9, image acquisition unit 8 and display unit 10, and described main computer 3 is the system control general hub, first it receives main hand The position information of the master hand 11 sent by the information collection unit 12, and the information is sent to the slave hand control computer 4 to realize the motion control of the slave hand 6; secondly, it receives the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com