A cement-based waterproof coating

A waterproof coating and cement-based technology, which is applied in the field of building materials, can solve the problems of low cost, poor treatment effect, and limited application range, etc., and achieve good base-level adaptability, good outdoor durability, and improved tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

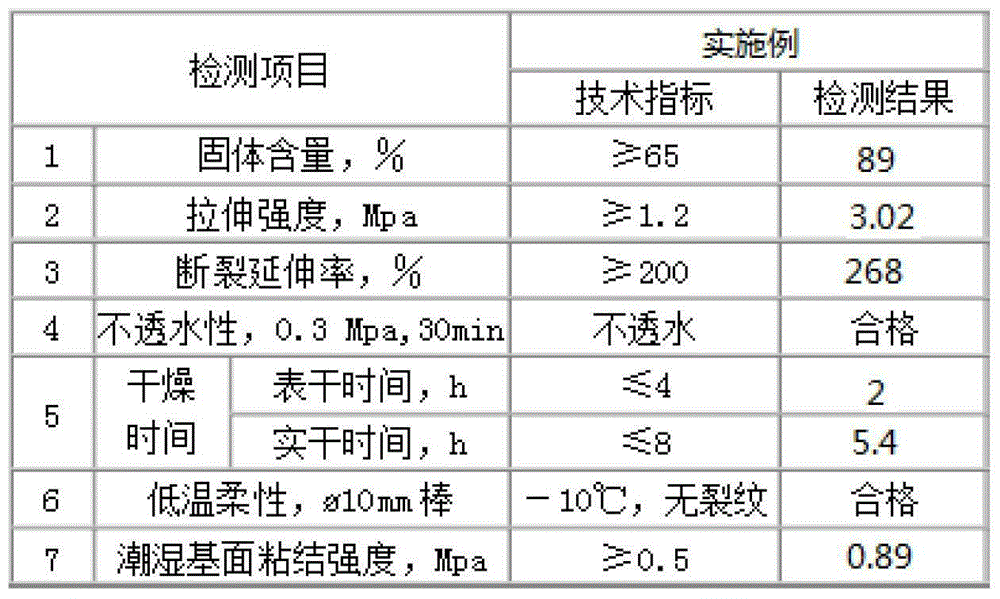

Examples

Embodiment 1

[0026] The cement-based waterproof coating includes the following components and the ratio of parts by weight of each component is: Portland cement: 80 parts; polyacrylate emulsion: 40 parts; quartz sand: 25 parts; quartz powder: 25 parts; Material: 5 parts; Sodium silicate: 4 parts; Silicone: 0.5 parts; Triethanolamine: 0.6 parts; Polyacrylate: 0.2 parts.

Embodiment 2

[0028] The cement-based waterproof coating includes the following components and the ratio of parts by weight of each component is: Portland cement: 50 parts; ethylene-vinyl acetate copolymer emulsion: 60 parts; quartz sand: 30 parts; quartz powder: 20 parts; Mineral admixture: 10 parts; Sodium silicate: 6 parts; Silicone: 0.1 part; NNO: 0.3 part; Melamine polyester: 0.5 part.

Embodiment 3

[0030] The cement-based waterproof coating includes the following components and the ratio of parts by weight of each component is: Portland cement: 60 parts; ethylene-vinyl acetate copolymer emulsion: 50 parts; quartz sand: 27 parts; quartz powder: 23 parts; Mineral admixture: 8 parts; Sodium silicate: 5 parts; Silicone: 0.3 parts; MF: 0.5 parts; Melamine polyester: 0.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com