Preparation method of nano montmorillonite modified resin-based carbon foam heat-insulating material

An insulating material and resin-based technology, which is applied in the field of preparation of nano-montmorillonite modified resin-based carbon foam insulating materials, can solve the problems of complex heat transfer channels, affecting the thermal conduction effect of carbon foam materials, and the like, so as to improve the thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 15g and 58g of formaldehyde and phenol respectively and put them into a three-necked flask. At the same time, add NaOH with a concentration of 3wt.%, and heat in a water bath to 90°C for reaction; when the reaction system reaches an appropriate viscosity, stop heating to obtain a thermosetting phenolic resin.

[0022] Weigh 1.75g of hollow microspheres and add them to 3g of liquid phenolic resin in batches, perform mechanical stirring and ultrasonic dispersion alternately for 1 hour, inject into the mold for molding; put it into a drying oven after standing at room temperature for 24 hours, cure at 80°C for 12 hours, and then raise the temperature Cured at 150°C for 24 hours to obtain phenolic foam.

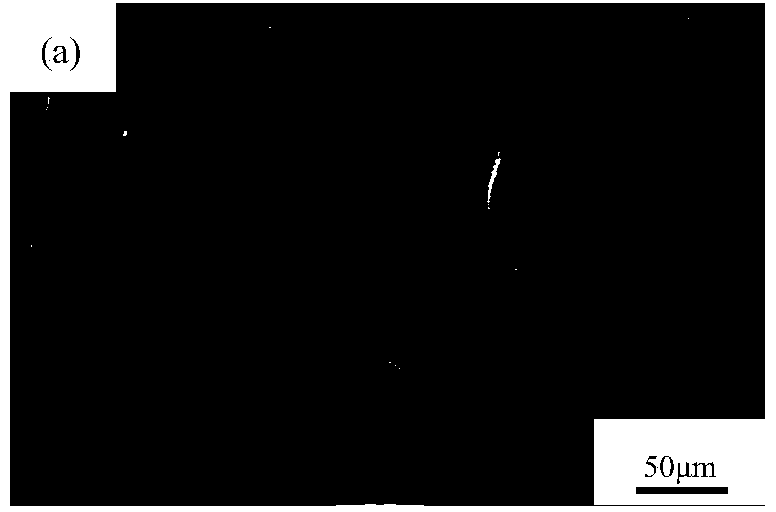

[0023] Put the phenolic foam into a vacuum resistance furnace, and slowly raise the temperature to 800 °C under the protection of Ar gas for carbonization treatment to obtain a pure carbon foam sample, whose microstructure is as follows: figure 1 shown.

[0024] T...

Embodiment 2

[0026] Weigh 15g and 58g of formaldehyde and phenol respectively and put them into a three-necked flask. At the same time, add NaOH with a concentration of 3wt.%, and heat in a water bath to 90°C for reaction; when the reaction system reaches an appropriate viscosity, stop heating to obtain a thermosetting phenolic resin.

[0027] Weigh 1.75g of hollow microspheres and 0.1425g of montmorillonite particles, add them to 3g of liquid phenolic resin in batches, perform mechanical stirring and ultrasonic dispersion alternately for 1 hour, inject them into molds and press them into molds; put them in a drying oven after standing at room temperature for 24 hours , cured at 80°C for 12h, and then heated to 150°C for 24h to obtain montmorillonite modified phenolic foam.

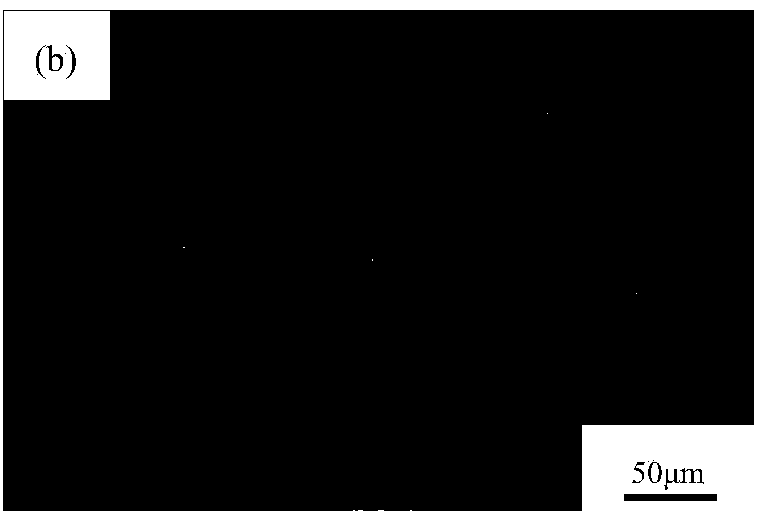

[0028] The obtained modified phenolic foam was placed in a vacuum resistance furnace, and the temperature was slowly raised to 800 °C under the protection of Ar gas for carbonization treatment to obtain a sample of m...

Embodiment 3

[0031] Weigh 15g and 58g of formaldehyde and phenol respectively and put them into a three-necked flask. At the same time, add NaOH with a concentration of 3wt.%, and heat in a water bath to 90°C for reaction; when the reaction system reaches an appropriate viscosity, stop heating to obtain a thermosetting phenolic resin.

[0032] Weigh 1.75g of hollow microspheres and 0.3325g of montmorillonite particles, add them in batches to 3g of liquid phenolic resin, alternately perform mechanical stirring and ultrasonic dispersion for 1h, inject them into molds and mold them; put them in a drying oven after standing at room temperature for 24h , cured at 80°C for 12h, and then heated to 150°C for 24h to obtain montmorillonite modified phenolic foam.

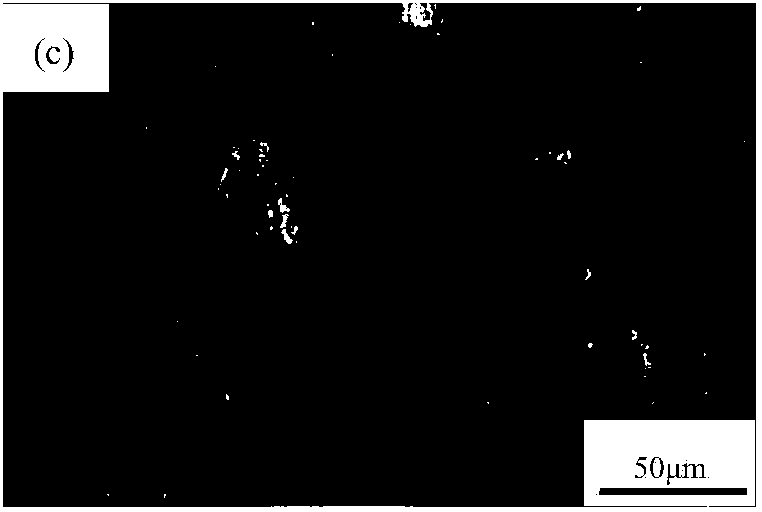

[0033] The obtained phenolic foam was placed in a vacuum resistance furnace, and the temperature was slowly raised to 800 °C under the protection of Ar gas for carbonization treatment to obtain a montmorillonite modified carbon foam samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com