Micro-emulsion type oil stain cleaning agent and preparation method thereof

A technology of microemulsion and cleaning agent, which is applied in the direction of detergent composition, chemical instrument and method, soap detergent composition, etc., can solve the problems of narrow application range, etc., achieve narrow particle size distribution, simple preparation method, and easy transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

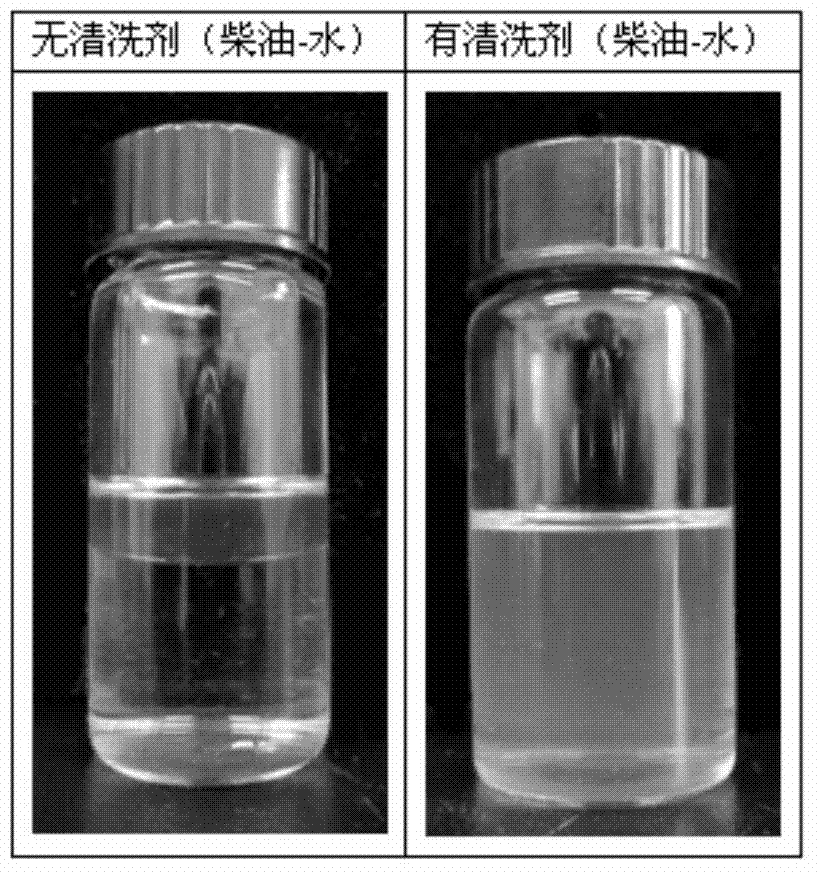

Method used

Image

Examples

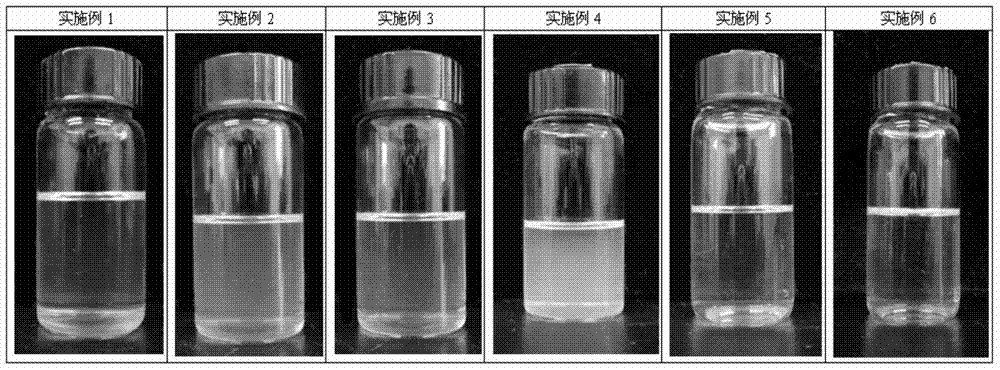

Embodiment 1

[0020] Based on 100 parts by weight, get 60 parts of 40wt% CaCl 2 Aqueous solution, 5 parts of C12EO9, 5 parts of AES, 1.6 parts of n-butanol, 28.4 parts of 5# white oil. Then put them together in a reactor and mix evenly, and stir at a speed of 300 rpm for 12 minutes at normal temperature to form a microemulsion type oil stain cleaning agent.

[0021] Investigate the solubilization ability of the microemulsion type cleaning agent of the prepared microemulsion type cleaning agent to other types of oil phases of high temperature stability, long-term stability, low temperature stability and microemulsion type cleaning agent respectively according to the following methods:

[0022] 1. Stability measurement:

[0023] Long-term stability: Place the product statically for a long time, observe the appearance, and pay attention to whether there is a clear delamination.

[0024] High-temperature stability: Place the sample in a high-temperature roller heating furnace at 120°C for 15-...

Embodiment 2

[0031] Based on 100 parts by weight, take 55 parts of 50wt% NaCl aqueous solution, 10 parts of a mixture of Span60 and Tween20 in a weight ratio of 1:1, 5 parts of SDS, 3 parts of ethanol, and 27 parts of diesel oil. Then put them together in a reactor and mix them evenly, and stir at a speed of 50 rpm for 20 minutes at normal temperature to form a microemulsion type oil stain cleaning agent.

[0032] Investigate the feature of microemulsion type cleaning agent by the method of embodiment 1, data is as follows:

[0033] Appearance

Embodiment 3

[0035] Based on 100 parts by weight, get 63 parts of 45wt% Na 2 SO 4 Aqueous solution, 7 parts of C12EO4, 10 parts of AS, 2 parts of propanol, 18 parts of waste oil. Then they are placed together in a reactor and mixed evenly, and stirred at a speed of 100 rpm for 18 minutes at normal temperature to form a microemulsion type oil stain cleaning agent.

[0036] Investigate the feature of microemulsion type cleaning agent by the method of embodiment 1, data is as follows:

[0037] Appearance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com