Treatment method for comprehensively recovering valuable elements from laterite-nickel ore

A technology of laterite nickel ore and a treatment method, which is applied in the field of metallurgy, can solve the problems of difficult extraction, complicated operation and low recovery rate, and achieves the effects of improving leaching efficiency and improving treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

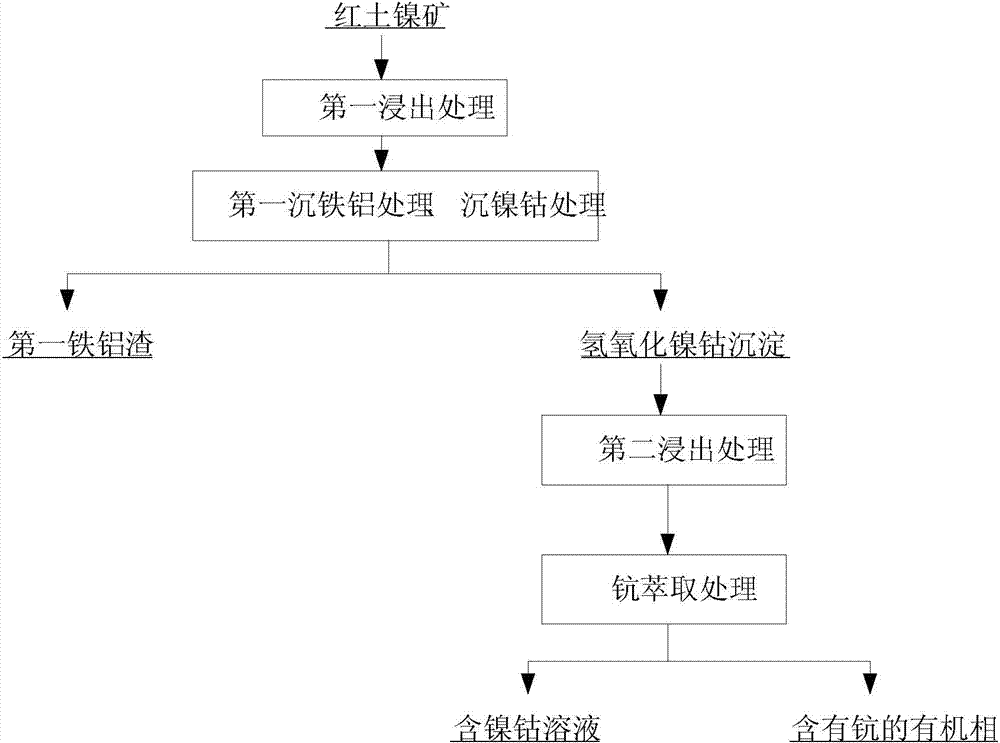

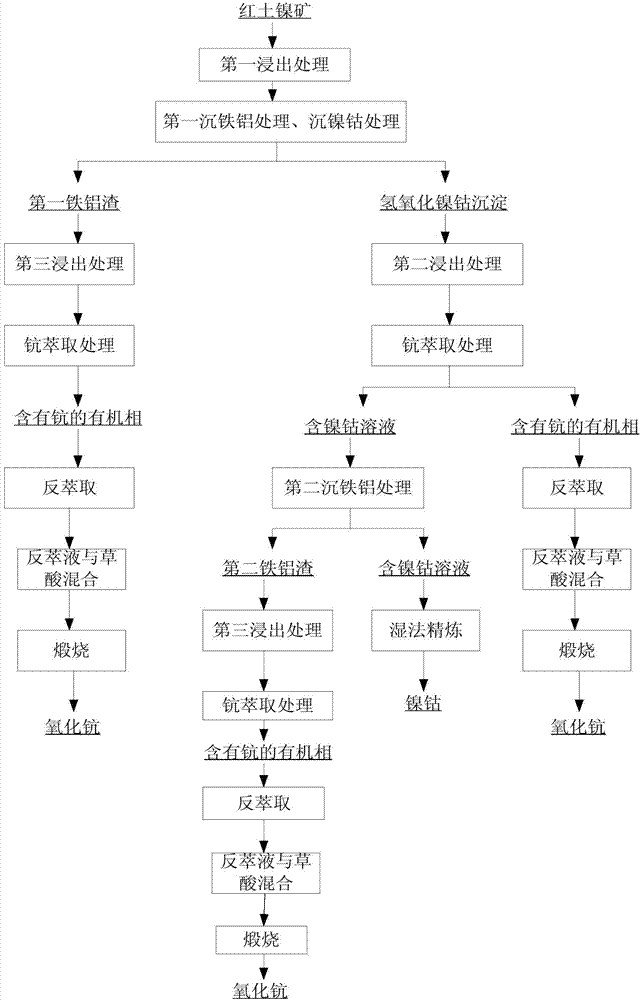

Method used

Image

Examples

Embodiment 1

[0043] The element content of a laterite nickel ore is shown in Table 1, wherein the content of scandium is 0.0033%.

[0044] Table 1 Element content of laterite nickel ore and its concentration in high pressure acid leaching solution

[0045] the element

Content in laterite nickel ore (%)

Concentration in pickling solution (g / L)

Ni

1.07

3.85

co

0.1

0.32

Cu

<0.02

0.01

Fe

41.9

1.32

mn

0.653

2.05

Zn

〈0.05

0.11

Pb

〈0.02

<0.001

Si

7.15

0.094

Al

1.83

1.69

Ca

0.157

0.14

Mg

1.98

3.59

Cr

0.5

0.022

sc

0.0033

0.0117

[0046] The above-mentioned laterite nickel ore is leached with sulfuric acid in an autoclave at a temperature of 255 degrees Celsius and a pressure of 5 MPa. Most of the valuable metals scandium (0.0117g / L), nickel (3.85g / L), and cobalt (0.32g / L) enter the hig...

Embodiment 2

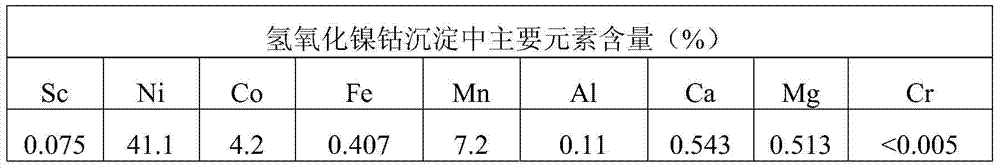

[0055] See Table 2 for the element content in a nickel hydroxide cobalt precipitate. Take the above-mentioned scandium hydroxide nickel cobalt precipitate, according to the solid-liquid ratio S:L=1:5, add 20% (mass percentage) sulfuric acid solution, stir and react for leaching, filter, and collect the filtrate. The filtrate mainly contains Ni, Co, Mn, Sc, Fe, Al, Ca.

[0056] Take the above-mentioned scandium hydroxide nickel cobalt sulfuric acid leaching solution, adjust the pH value to 0.5, according to the water phase: organic phase = 5:1, add the kerosene solution containing 10% N235 + 5% N503 to carry out the extraction reaction. The extraction percentage of Sc was 99.8%, and the extraction rates of Ni, Co, Fe, and Al were 0.1%, 0.2%, 1.0% and 0.2%, respectively. The extraction rate of impurities is low and separated from scandium. The loaded organic phase is washed with 5% sulfuric acid solution for 4 stages according to the water phase: organic phase = 2:1, and a sma...

Embodiment 3

[0060] The element content in the sulfuric acid leaching solution of a laterite nickel ore is shown in Table 1. The pH is adjusted to 3.8 with lye, so that the iron and aluminum in the leaching solution form iron and aluminum slag, and the scandium and iron and aluminum impurities are separated. Further, the pH is adjusted to 8.0 with lye, and the nickel-cobalt is precipitated to obtain the nickel-cobalt hydroxide precipitate. Scandium was enriched with the precipitation of nickel and cobalt hydroxide, with a content of 0.139%. The element content is shown in Table 3.

[0061] Table 3 Main element content in nickel hydroxide cobalt precipitation

[0062]

[0063]Take the above-mentioned scandium hydroxide nickel cobalt precipitate, according to the solid-liquid ratio S:L=1:5, add 20% (mass percentage) sulfuric acid solution, stir and react for leaching, filter, collect the filtrate to make the leachate, the filtrate mainly contains Ni, Co, Mn , Ca, Mg, Sc, Fe, Al.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com