Variable-frequency microperforated pipe silencer with variable perforation section lengths

A technology of micro-perforation and muffler, which is applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problem of single muffler frequency band, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

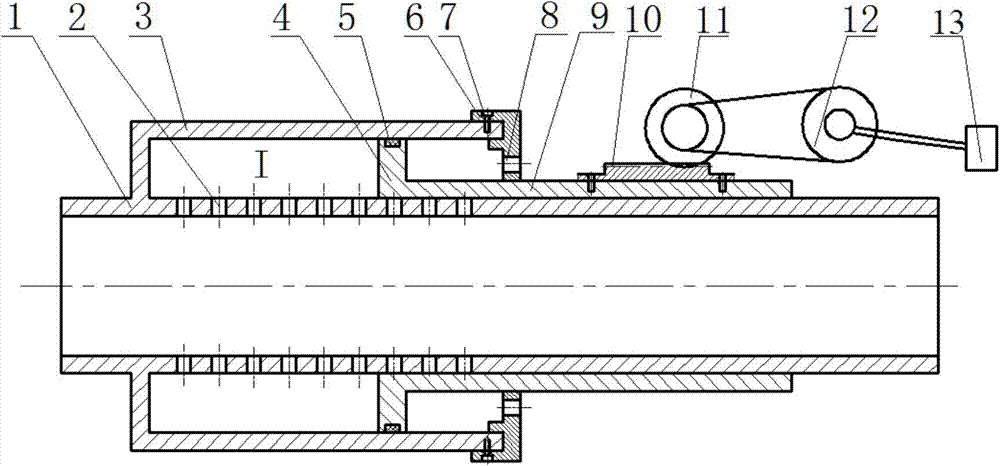

[0022] A frequency-tunable micro-perforated tube muffler with variable perforated section length, such as figure 1 As shown, the main pipe 1 is included, and the inside of the main pipe 1 is a fluid channel for connecting the noise source. In practical applications, one end of the main pipe 1 is connected to the exhaust pipe or intake pipe of a rotating machine such as an engine, a motor or a fan. The muffler also includes a sleeve piston 9, an outer pipe 3 and a sleeve position adjusting device. The middle section of the main pipeline 1 is a perforated pipe 2 provided with micro-perforations. The diameter of the micro-perforated holes on the perforated pipe 2 is 0.1-2mm, and the perforation rate of the micro-perforated pipes 2 is 1-5%. The wall thickness is 0.5-2mm. The sleeve piston 9 is closely sleeved on the outside of the main pipe 1, and the head of the sleeve piston 9 is provided with a disc 4, and the tail of the sleeve piston 9 is connected with the sleeve position a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com