Cell structure of super junction semiconductor device and technology realizing method

A super junction and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as device damage and increased avalanche tolerance of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

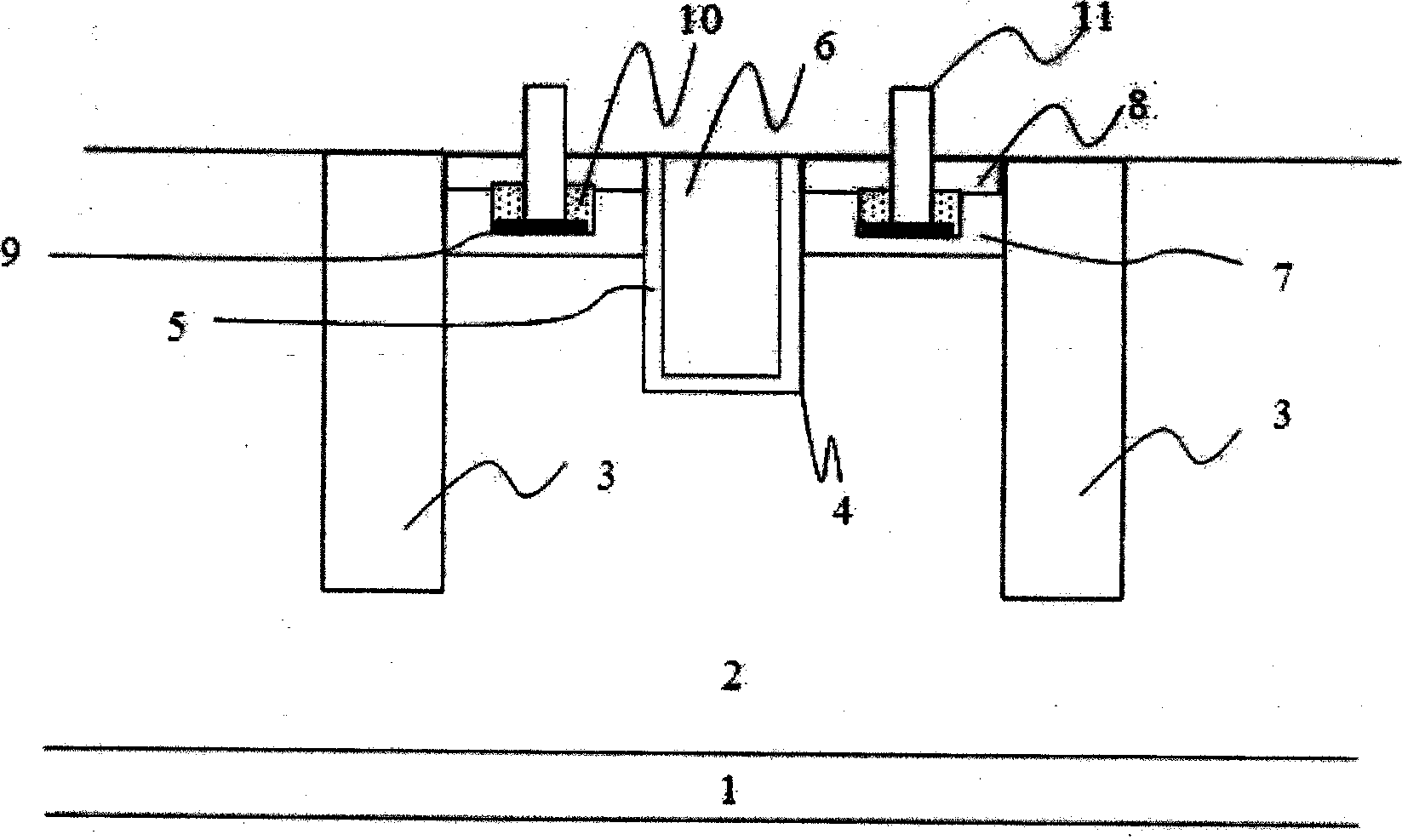

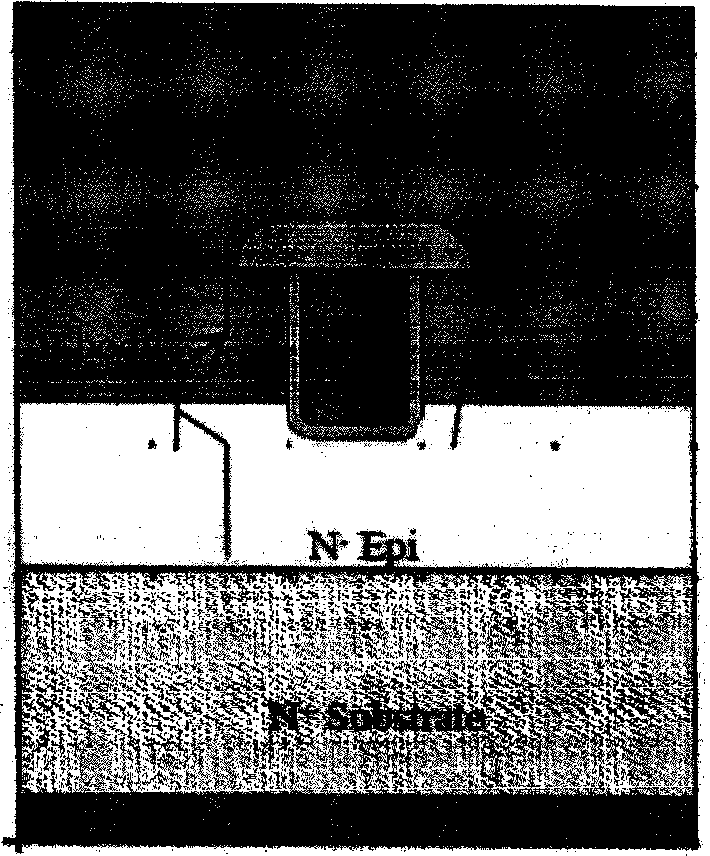

[0019] The invention discloses a cell structure and process realization method of a deep-groove super junction semiconductor device, including a first-type heavily doped region [1] of the substrate of the device; located in the first-type heavily-doped region of the substrate The first type of epitaxial drift region [2] above [1]; the second type of epitaxial column region [3] located above the substrate heavily doped region [1] and on both sides of the epitaxial drift region [2] ]; there is a gate trench [4] between the second type of epitaxial column area [3]; the gate polysilicon [6] is inside the trench; the gate trench [4] is connected to the gate There is a dielectric isolation layer [5] between the extremely polysilicon [6]; a second-type doped well region [7] is formed between the gate trench [4] and the semi-insulating column region [3]; the The source region [8] doped with the first type is formed on the upper part of the well region; the source region [8] and the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com