Light emitting diode with reflector protective layer

A technology of light-emitting diodes and protective layers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of silver oxidation, reduction of light-emitting efficiency of light-emitting diodes, reduction of reflection efficiency of reflective layer 4, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereby, the detailed content and technical description of the present invention are further described with examples.

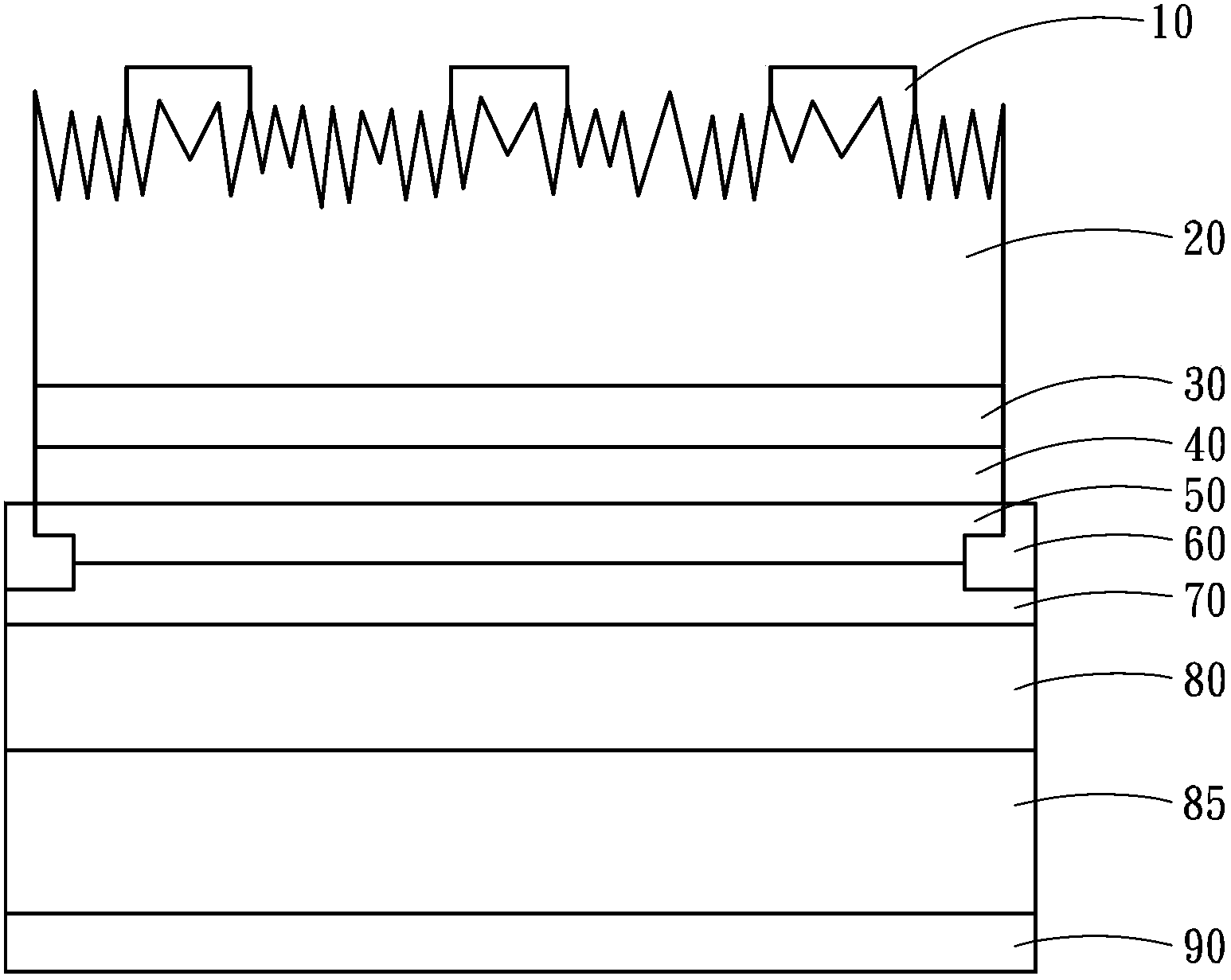

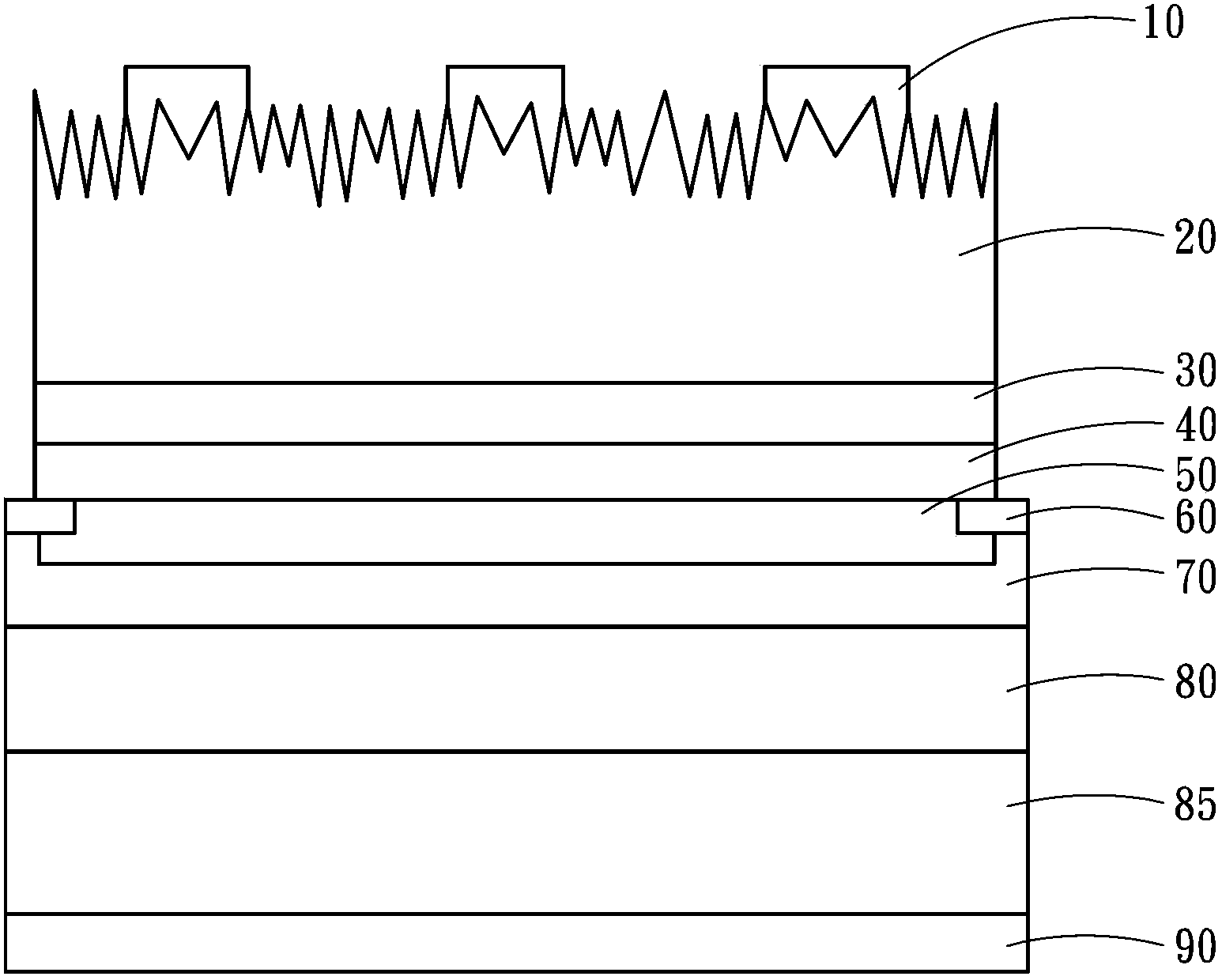

[0019] see again figure 2 and image 3 As shown, the present invention is a light-emitting diode with a mirror protection layer, which includes an N-type electrode 10, an N-type semiconductor layer 20, a light-emitting layer 30, a P-type semiconductor layer 40, a metal reflective layer 50, A protection layer 60 , a buffer layer 70 , a bonding layer 80 , a permanent substrate 85 and a P-type electrode 90 .

[0020] Wherein the N-type electrode 10 is formed on one side of the N-type semiconductor layer 20, the light-emitting layer 30 is formed on the side of the N-type semiconductor layer 20 away from the N-type electrode 10, and the P-type semiconductor layer 40 is formed on the light-emitting layer. The side of the layer 30 away from the N-type semiconductor layer 20 , the sandwich structure formed by the N-type semiconductor layer 20 , the light-emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com