Method of distribution of absorption of laser crystal radial-direction non-uniform doping control pump light

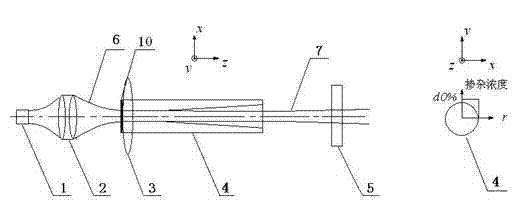

A laser crystal, non-uniform technology, applied in the device, laser, laser parts and other directions that control the output parameters of the laser, can solve the problems of end face explosion, film peeling, affecting the normal operation of the laser, etc., to achieve high conversion efficiency, high beam Quality, avoid the effect of peeling off the crystal end film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

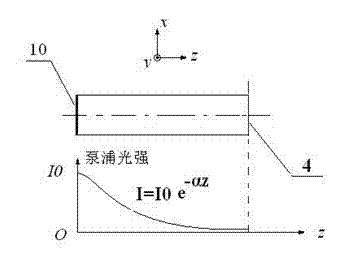

Method used

Image

Examples

Embodiment 1

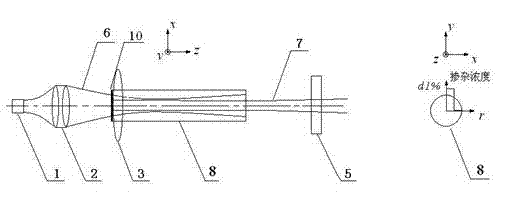

[0022] Such as image 3 As shown, replace with radial step doped crystal 8 figure 1 In the uniformly doped crystal 4, under the condition that the pump light distribution is determined, by changing the doping concentration and doping range of the step-doped crystal 8, the control of the gain region and temperature distribution is realized. At this time, the pump light does not need to be focused on the crystal end face, and the absorption distribution of the pump light in the crystal is determined by the doping range of the radially stepped doped crystal 8. In this way, the thermal lens effect at the crystal pump end face 10 is weakened, It can effectively increase the injection power of the crystal end face, which is beneficial to obtain high power and high beam quality.

Embodiment 2

[0024] Such as Figure 4 As shown, replace with radial continuous doped crystal 9 figure 1 The uniformly doped crystal 4 in , under the condition that the pump light distribution is determined, through the optimization of the radial continuous doping concentration distribution, such as parabolic distribution, can realize the control of the crystal absorption distribution (that is, the gain distribution), and reduce the crystal The radial temperature difference suppresses the thermal effect and obtains a large fundamental mode volume. The spatial coincidence of the gain region and the distribution region of the fundamental mode of the resonator can be achieved without focusing the pump light near the pumping end face of the crystal, thereby greatly increasing the injection power at the end face while ensuring high beam quality. The design and optimization process of the radial doping concentration distribution of the crystal mainly involves the calculation of the steady-state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com