Controller applied to multiphase motor speed adjusting system

A multi-phase motor and speed control system technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of limited content of human-computer interaction, limited external interface resources, insufficient busbar design, etc., to achieve flexible and reliable Scalable design, high reliability, and the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

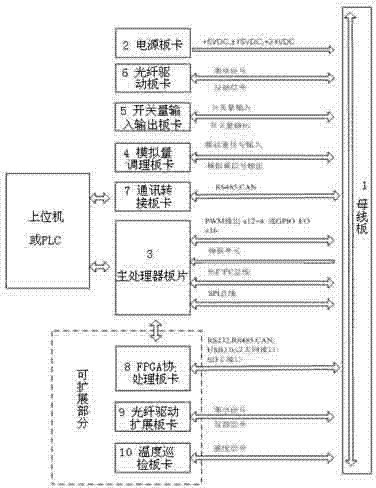

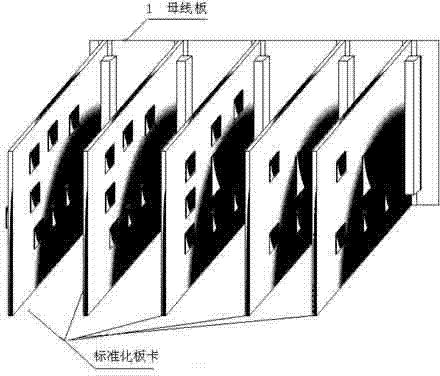

[0031] Embodiment 1: is basic embodiment of the present invention. like figure 1 , 2 As shown, a controller applied to a multi-phase motor speed control system includes a bus board 1, a power board 2, a main processor board 3, an analog conditioning board 4, a switching input and output board 5, and an optical fiber The drive board 6 and the communication adapter board 7; the power supply board 2 provides power for the above-mentioned other boards through the bus board 1; the drive and feedback signal of the optical fiber drive board 6), and the switch of the switch input and output board 5 Quantity signal, the analog signal of the analog conditioning board 4, and the communication signal of the communication adapter board 7 carry out information interaction with the main processor board 3 through the bus board 1; the communication adapter board 7 and the main processor board 3 Communicate with the upper computer at least respectively.

Embodiment 2

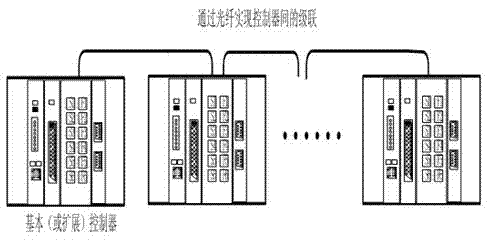

[0032] Embodiment 2: is a further embodiment. Different from the above-mentioned embodiment 1, it also includes an FPGA co-processing board 8, an optical fiber drive expansion board 9 and a temperature inspection board 10; The temperature signal communicates with the FPGA co-processing board 8 through the bus-type bus board 1; the FPGA (Field-Programmable Gate Array Field Programmable Gate Array) co-processing board 8 communicates through the RS232 interface, RS485 interface, and USB2.0 interface , the Ethernet interface, and the SD card interface at least communicate with the host computer; the FPGA co-processing board 8 and the main processor board 3 are interconnected through an inter-board parallel bus.

Embodiment 3

[0033] Embodiment 3: is a further embodiment. The difference from the first embodiment above is that the main processor board 3 , the analog adjustment board 4 , the switch input and output board 5 and the optical fiber driver board 6 are all provided with programmable devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com