Milk processed food using whey and manufacturing method thereof

A heating process and process technology, applied in the field of milk processed food and its manufacturing, can solve the problems of limited use, insufficient utilization, limited use, etc., and achieve the effects of obtaining nutritional physiology, less sour or miscellaneous taste, and efficient intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The effect of the type of WPC and WPI on the taste of edible gel

[0090] For each sample number (sample numbers: 1-1, 1-2, and 1-3), milk-processed foods (edible gels) were produced with the ingredients shown in Table 1.

[0091] The raw materials (except lactic acid bacteria) of each sample were adjusted in the compounding ratio described in Table 1.

[0092] Table 1

[0093] Table 1. Effects of types of WPC and WPI on the taste of processed dairy foods

[0094]

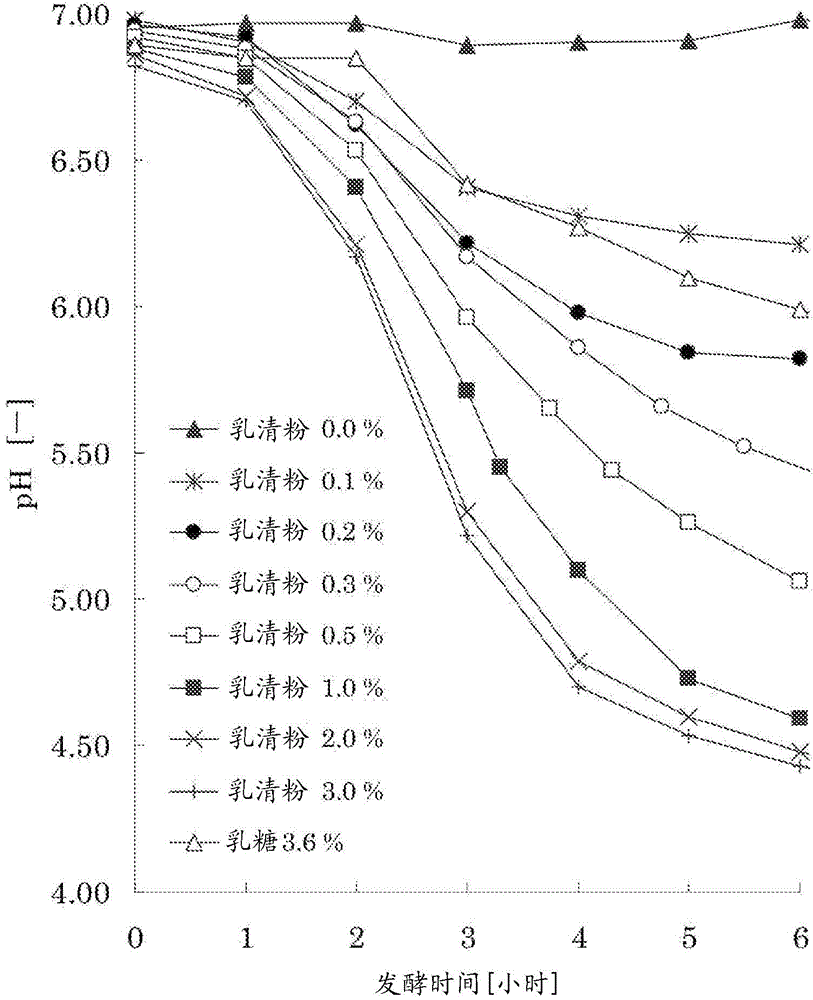

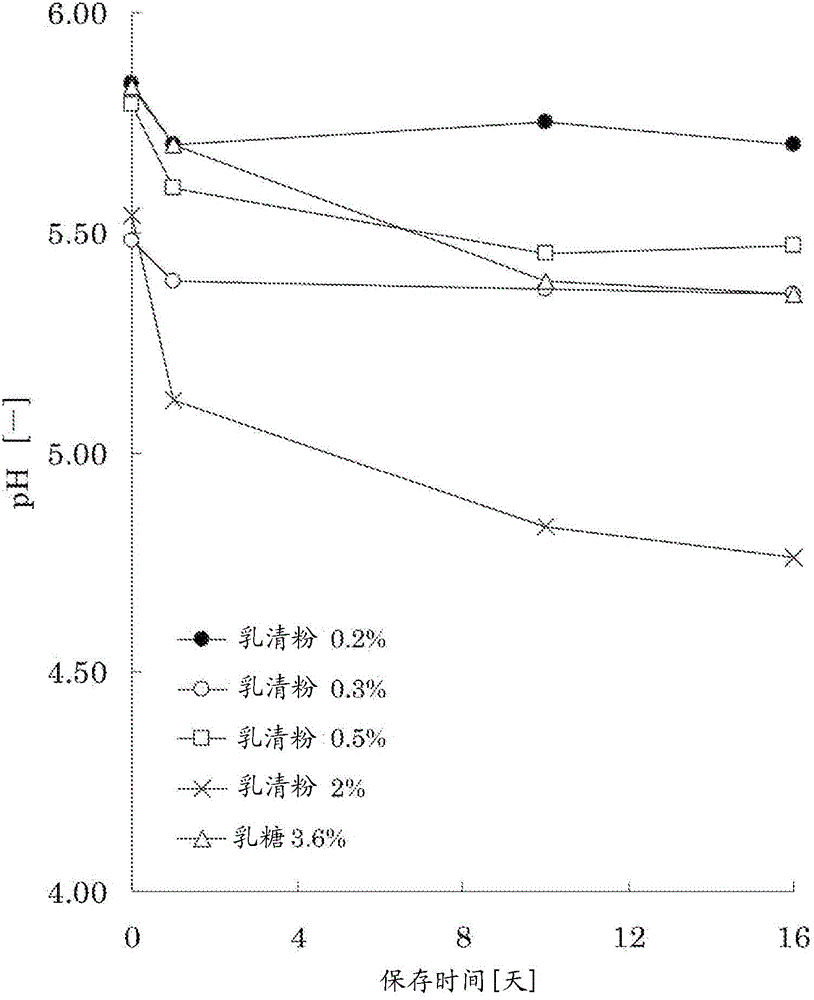

[0095] After adjusting and dissolving raw materials (excluding lactic acid bacteria), heat sterilization was performed at 95°C for 5 minutes each. After heating, cool the raw material to 40 to 45°C, and add 10 5 to 10 7 CFU / mL of lactic acid bacteria (Lactobacillus bulgaricus and Streptococcus thermophilic lactis isolated from Meiji Bulgarian yoghurt, Meiji Dairy Co., Ltd.) were then filled into containers of various shapes. After filling, the container was moved to an incubator and fermented at 43° ...

Embodiment 2

[0098] Effect of β-lactoglobulin (β-LG) ratio in total protein on taste of edible gels

[0099] In the same way as in Example 1, each sample number (sample number: 2-1, 2-2, 2-3, 2-4, and 2-5) was prepared with the ratio of raw materials shown in Table 2 Dairy processed food (edible gel).

[0100] Table 2

[0101] Table 2. The effect of the ratio of β-LG on the taste of dairy processed food

[0102]

[0103] Gels with a ratio (ratio) of β-lactoglobulin in the total protein of the raw material of 74% or more after sensory evaluation of the gels of each sample number (specialized panel: 5 persons) (sample numbers: 2-4 and 2-5) to obtain a pure taste. On the other hand, in the samples (sample numbers: 2-1, 2-2, and 2-3) in which the ratio (proportion) of β-lactoglobulin in the total protein was low, a pure taste could not be obtained. In addition, the color difference (L value, a value, b value) of the obtained gel was measured with a spectrocolorimeter Kara-Analaizer TC18...

Embodiment 3

[0110] Effect of β-lactoglobulin (β-LG) ratio in total protein on physical properties

[0111] In the same way as in Example 1, each sample number (sample number: 3-1, 3-2, 3-3, 3-4, and 3-5) was prepared with the ratio of raw materials shown in Table 4 Dairy processed food (edible gel).

[0112] Table 4

[0113] Table 4. The effect of the concentration of β-LG on the taste of dairy processed food

[0114]

[0115] After checking the breaking strength and sensory evaluation of the gels of each sample number (specialized panel: 5 persons), the concentration of β-lactoglobulin in all the gels was 2.16% or more (sample number: 3- 2, 3-3, 3-4 and 3-5) for pure flavor. Also, gels having moderate hardness of 41.0 g or more were obtained among these gels.

[0116] In addition, the inspection of the breaking strength was measured on the P5 / S axis using Techschana Raizer TA.XT Plus (Stable Micro Systems, SMS Corporation).

[0117] Further, Table 5 shows the results of detailed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com