Liquid crystal emulsifier composition, and preparation method and application thereof in cosmetics

An emulsifier and composition technology, applied in the field of daily chemicals, can solve the problems of formula composition and preparation process limitation, use limitation of liquid crystal emulsifier, influence on the formation of liquid crystal structure, etc., to achieve good emulsification effect, easy formation, skin delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

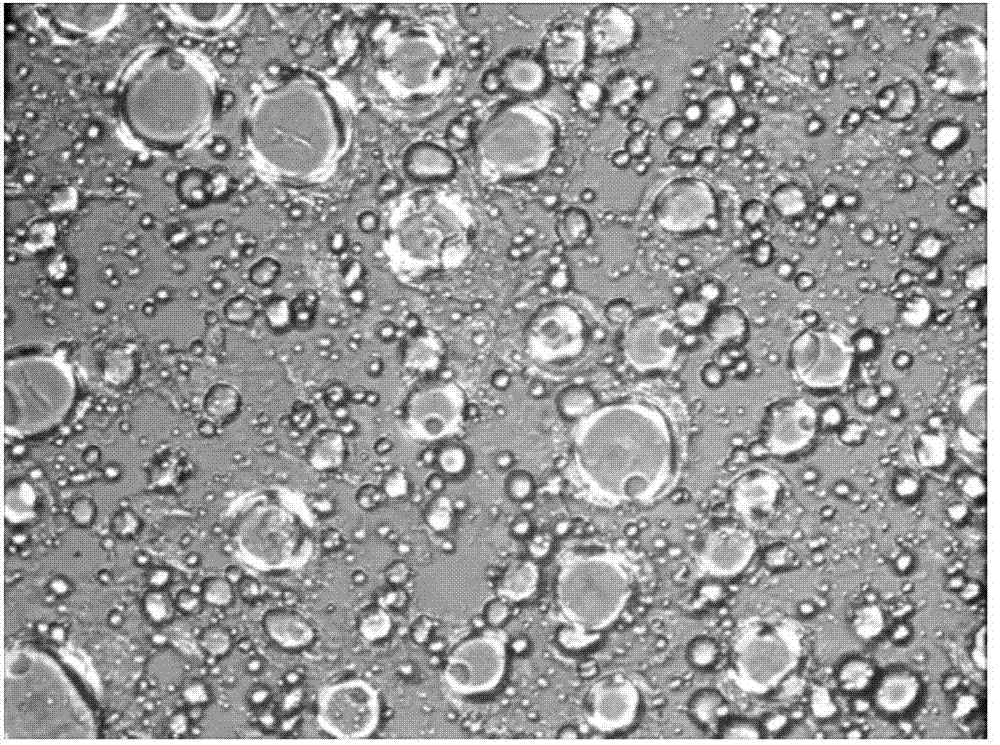

Image

Examples

Embodiment 1

[0039] 50 parts by mass of stearyl phosphate (commercially available product, containing 40 parts by mass of stearyl phosphate monoester, 8.75 parts by mass of stearyl phosphate diester, 1.25 parts by mass of free phosphoric acid), 20 parts by mass of C 16 Add fatty alcohol (cetyl alcohol) and 30 parts by mass of ceteareth-2 into the reaction kettle, heat up to 85°C and melt, then depressurize to -0.1MPa, homogenize at 3000r / min for 5min, and keep warm at 85°C for 1h , and then add 0.05 parts by mass of 2,6-di-tert-butyl-4-methylphenol (BHT). Then the temperature is lowered and the material is discharged to obtain the liquid crystal emulsifier composition I.

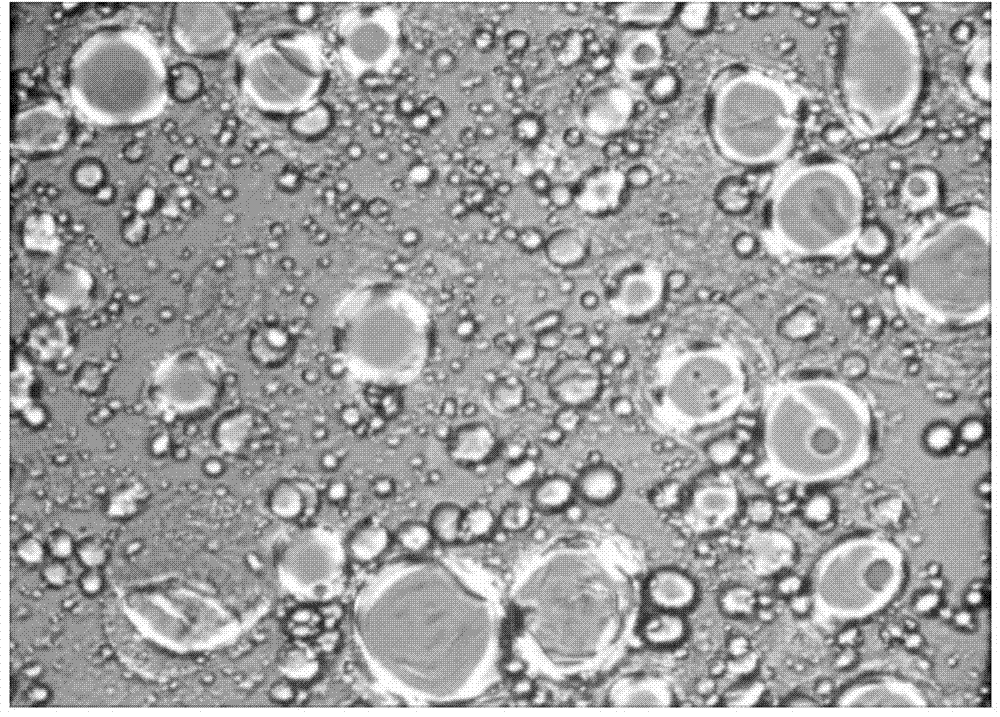

Embodiment 2

[0041] 60 parts by mass of eicosyl phosphate (commercially available product, containing 52.5 parts by mass of eicosyl phosphate monoester, 6.0 parts by mass of eicosyl phosphate diester, 1.5 parts by mass of free phosphoric acid), 30 parts by mass of C 18 Add fatty alcohol (stearyl alcohol) and 10 parts by mass of ceteareth-4 into the reaction kettle, heat up to 95°C and melt, then depressurize to -0.05MPa, homogenize at 4500r / min for 5min, and keep warm at 95°C for 1h , then add 0.05 parts by mass of vitamin E acetate. Then the temperature is lowered and the material is discharged to obtain the liquid crystal emulsifier composition II.

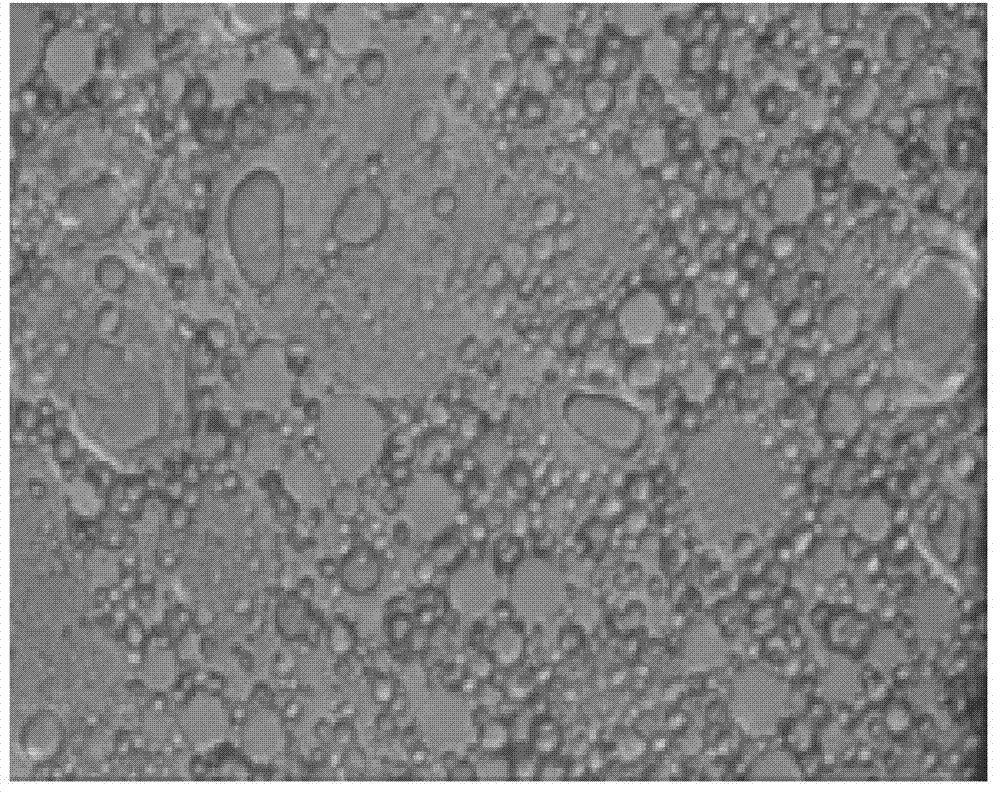

Embodiment 3

[0043] 55 parts by mass of behenyl phosphate (commercially available product, containing 46.75 parts by mass of behenyl phosphate monoester, 7.15 parts by mass of behenyl phosphate diester, 1.10 parts by mass of free phosphoric acid), 25 parts by mass of C 20 Add fatty alcohol (eicosanol) and 20 parts by mass of ceteareth-6 into the reaction kettle, heat up to 90°C and melt, then depressurize to -0.08MPa, homogenize at 5000r / min for 5min, and keep at 90°C for 1h , and then add 0.05 parts by mass of dibutylhydroxytoluene. Then the temperature was lowered and the material was discharged to obtain the liquid crystal emulsifier composition III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com