Integrated large micro-wave sterilization disinfection processor for medical wastes

A technology of medical waste and processing machine, which is applied in the field of medical equipment, can solve problems such as human health hazards, difficulty in decomposition, waste of land resources, etc., and achieve the effects of simple operation, short processing time, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

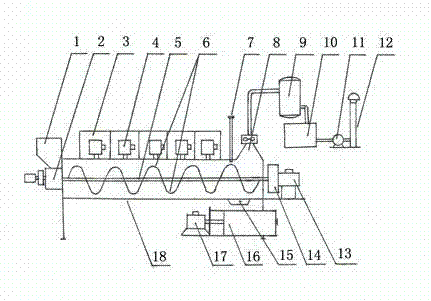

[0011] As shown in the figure, the integrated large-scale medical waste micro-sterilization wave disinfection treatment machine is composed of a feeding hopper 1, a grinder 2, a microwave bin 3, a magnetron microwave generator 4, a spiral shaft conveyor 5, and a leaf dragon blade 6. , Steam intake pipe 7, air collecting hopper with exhaust fan 8, condenser 9, biological deodorization device 10, exhaust fan 11, exhaust tube 12, motor 13, reducer 14, slag outlet 15, waste slag compression device 16, Composed of a pushing motor 17 and a body 18; the upper part of the body 18 is provided with a microwave bin 3 and a steam inlet pipe 7, and a magnetron microwave generator 4 is provided inside the microwave bin 3; a feeding hopper with a crusher 2 is provided on one side of the body 18 1. An air collecting hopper 8 with an exhaust fan is set on the other side; the air collecting hopper 8 with an exhaust fan is connected to the condenser 9 by a pipe, and the condenser 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com