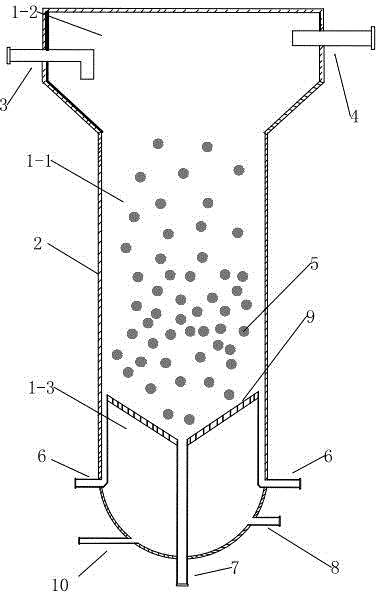

Granular Polysilicon Fluidized Bed Reactor

A silicon fluidized bed and reactor technology, applied in chemical instruments and methods, silicon, chemical/physical processes, etc., can solve problems such as uneven wall-attached reactions, and achieve the effects of reasonable layout, improved product purity, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

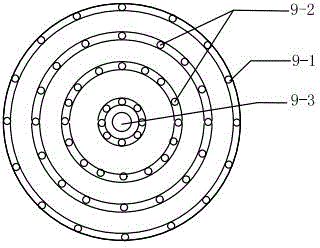

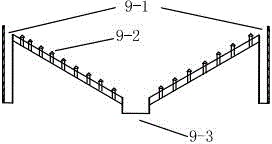

specific example 1

[0031] Specific example 1: Preheat the reaction raw material gas hydrogen and trichlorosilane to 700-800°C respectively, pass them into the gas buffer zone, and simultaneously pass the hydrogen covering gas into the reactor. The gas distributor 9 is used to pass part of the hydrogen into the reaction zone 1-1 along the wall, and the polysilicon seed preheated to 1000-1100 °C is passed into the reaction zone from the inlet 3 with the feed device. At this time, the reaction gas The temperature of the polysilicon seed crystal is kept at 1000-1100°C by the heater. At this time, the hydrogen gas starts to reduce trichlorosilane in the atmosphere of 1000-1100°C, and the polysilicon produced continuously gathers in the On the polysilicon seed crystal, as the reaction proceeds, the polysilicon particles continuously increase to the size set by the process, and then fall to the product collection device due to gravity. The product collection device is filled with inert gas to prevent o...

specific example 2

[0032] Specific example 2: Preheat the silane in the reactor to 500-600°C and then pass it into the gas buffer zone, and at the same time, cover the hydrogen gas into the reaction zone through the gas distributor. Use the gas distributor 8 to pass part of the hydrogen into the reaction zone along the inner wall of the reactor, and use the feeding device to introduce the silicon seed preheated to 700-800 °C into the reaction zone, and at this time, it is suspended in the reaction zone under the blowing of the reaction gas. In the zone, the surface temperature of the seed crystal particles is kept at 700-800°C by a heater, and silane gas is introduced. At this time, the silane gas decomposes in an atmosphere of 700-800°C, and decomposes to produce silicon and hydrogen. The produced silicon is continuously deposited on the surface of the silicon seed crystal. As the reaction progresses, the silicon particles continue to grow to the size set by the process, and fall into the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com