Antifog self-cleaning glass and preparation method thereof

A self-cleaning, anti-fog technology, applied in chemical instruments and methods, glass/slag layered products, metal/metal oxide/metal hydroxide catalysts, etc. Fog vision, unclear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

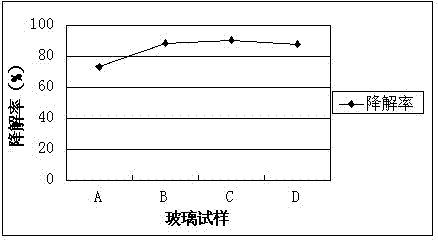

[0053] An anti-fog self-cleaning glass, comprising a glass substrate and an anti-fog self-cleaning film obtained by dipping and pulling on it, said TiO 2 thin film, that is, nano-α-Fe 2 o 3 to TiO 2 It is obtained by doping, wherein the doping ratio of Fe is calculated by molar ratio, that is, Fe:Ti is 0:100, 1.05:100, 1.1:100, 1.25:100 respectively.

[0054] The glass substrate is flat glass with a thickness of 4mm.

[0055] The above-mentioned preparation method of an anti-fog self-cleaning glass specifically comprises the following steps:

[0056] (1) Preparation of Fe-doped TiO by solution-gel method 2 Precursor titanium alkoxide gel

[0057] Calculated by molar ratio, that is, tetra-n-butyl titanate: absolute ethanol: glacial acetic acid: deionized water is a ratio of 1:10:1:1, and tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and deionized Solution X is obtained after mixing ionic water;

[0058] (2) Add nanometer α-Fe with Fe:Ti molar ratio...

Embodiment 2

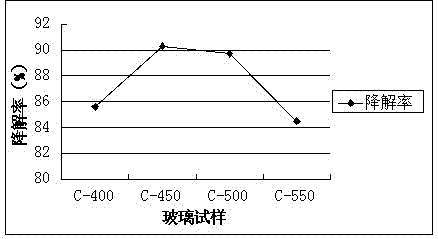

[0064] An anti-fog self-cleaning glass, comprising a glass substrate and an anti-fog self-cleaning film obtained by dipping and pulling on it, said TiO 2 thin film, that is, nano-α-Fe 2 o 3 to TiO 2 It is obtained by doping, wherein the doping ratio of Fe is calculated by molar ratio, that is, Fe:Ti is 1.1:100;

[0065] The substrate is flat glass with a thickness of 4 mm.

[0066] The above-mentioned preparation method of an anti-fog self-cleaning glass specifically comprises the following steps:

[0067] (1) Preparation of Fe-doped TiO by solution-gel method 2 Precursor titanium alkoxide gel

[0068] Calculated by molar ratio, that is, tetra-n-butyl titanate: absolute ethanol: glacial acetic acid: deionized water is a ratio of 1:10:1:1, and tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and deionized Solution X is obtained after mixing ionic water;

[0069] (2) Add nanometer α-Fe with a molar ratio of Fe:Ti of 1.1:100 to four equal volumes of solution ...

Embodiment 3

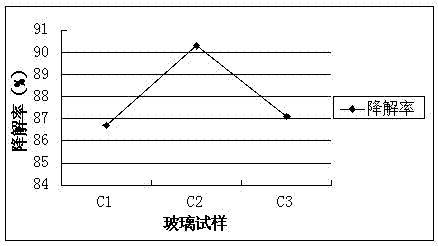

[0075] An anti-fog self-cleaning glass, comprising a glass substrate and an anti-fog self-cleaning film obtained by dipping and pulling on it, said TiO 2 thin film, that is, nano-α-Fe 2 o 3 to TiO 2 It is obtained by doping, wherein the doping ratio of Fe is calculated by molar ratio, that is, Fe:Ti is 1.1:100;

[0076] The glass substrate is flat glass with a thickness of 4mm.

[0077] The above-mentioned preparation method of an anti-fog self-cleaning glass specifically comprises the following steps:

[0078] (1) Preparation of Fe-doped TiO by solution-gel method 2 Precursor titanium alkoxide gel

[0079] Calculated by molar ratio, that is, tetra-n-butyl titanate: absolute ethanol: glacial acetic acid: deionized water is a ratio of 1:10:1:1, and tetra-n-butyl titanate, absolute ethanol, glacial acetic acid and deionized Solution X is obtained after mixing ionic water;

[0080] (2) Add nanometer α-Fe with Fe:Ti molar ratio of 1.25:100 to three equal volumes of soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com