A lightweight, shard-free bulletproof glass

A bulletproof glass, lightweight technology, applied in glass/slag layered products, lamination devices, laminations, etc., can solve the problems of splashing debris, light transmittance, poor thermal insulation and sound insulation, and achieve good flame retardancy and sound insulation. The effect of good performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Raw material preparation: cut, clean and dry the original glass sheet, and reserve it; cut and dry the polyurethane sheet, and set it aside; the drying temperature is 65°C, and the time is 4 hours;

[0029] (2) Combination: Laminate glass 5mm, PVB film 0.76mm, glass 5mm, PU film 1.26mm, PC board 5mm, PU film 0.63mm, PC board 4mm in sequence; the temperature of the lamination is 20°C and the humidity is 25%;

[0030] (3) Pre-pressing and exhausting: pre-pressing and exhausting the laminated composite materials; the pre-pressing temperature is 100°C, the cylinder pressure of the rubber roller is 0.6MPa, and the vacuum degree is 0.015MPa;

[0031] (4) High-pressure molding: send the pre-pressed composite material into the autoclave, keep the temperature and pressure for 50 minutes, then lower the temperature and release the pressure, cool, and exit the autoclave to obtain light bulletproof glass. Pressure 1.1MPa.

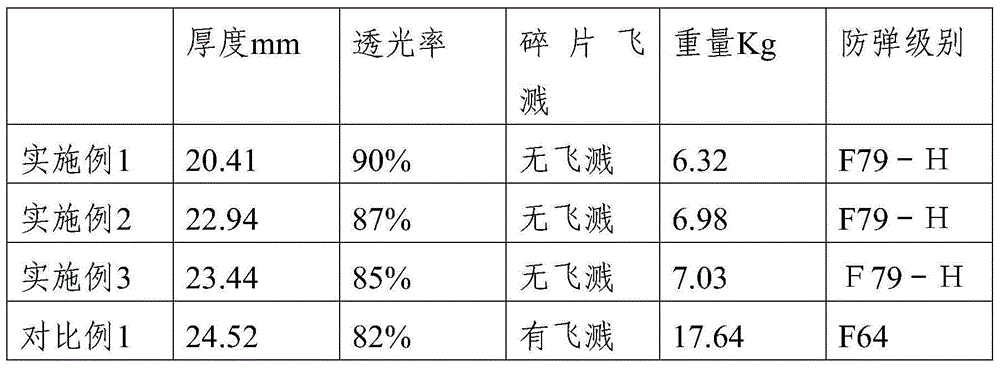

[0032] After testing, the bulletproof glass has an ar...

Embodiment 2

[0034] Bulletproof glass was prepared according to the method of Example 1.

[0035] In step 1), the drying temperature is 75°C and the drying time is 3h;

[0036] In step 2), the laminating temperature is 18°C and the humidity is controlled at 25%;

[0037] The order of raw material lamination is: glass 5mm, EVA film 0.80mm, glass 6mm, PA film 0.70mm, PC sheet 6mm, PU film 1.26mm, PC sheet 4mm;

[0038] In step 3), the pre-compression pressure is 0.7MPa, the temperature is 120°C, and the vacuum degree is 0.02MPa;

[0039] In step 4), the heat preservation and pressure holding conditions are: temperature 110° C., pressure 1.5 MPa, heat preservation and pressure holding time 60 minutes.

[0040] After testing, the bulletproof glass has an area of 420×420mm, a thickness of 22.84mm, a light transmittance of 87%, a flame-retardant performance of B1, a sound insulation of 18.83dB, and a weight of 6.98kg.

Embodiment 3

[0042] Bulletproof glass was prepared according to the method of Example 1.

[0043] In step 1), the drying temperature is 65°C and the drying time is 4h;

[0044] In step 2), the laminating temperature is 25°C and the humidity is controlled at 20%;

[0045] The order of raw material lamination is: glass 7mm, EVA film 0.62mm, glass 4mm, PA film 0.79mm, PC sheet 7mm, PU film 1.26mm, PC sheet 4mm;

[0046] In step 3), the pre-compression pressure is 0.5MPa, the temperature is 70°C, and the vacuum degree is 0.01MPa;

[0047] In step 4), the heat preservation and pressure holding conditions are: temperature 130° C., pressure 1.0 MPa, heat preservation and pressure holding time 40 minutes.

[0048] After testing, the bulletproof glass has an area of 420×420mm, a thickness of 23.44mm, a light transmittance of 85%, a flame-retardant performance of B1, a sound insulation of 19.21dB, and a weight of 7.03kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com