Sewage treatment unit and method using bioelectrochemistry to aid membrane bioreactor

The technology of a sewage treatment device and a bioreactor is applied in the field of bioelectrochemical auxiliary membrane bioreactor sewage treatment device, which can solve the problems of pollution, high operation cost, expensive membrane material, etc. The effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

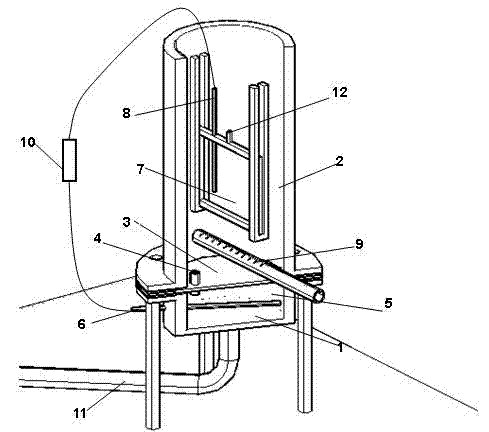

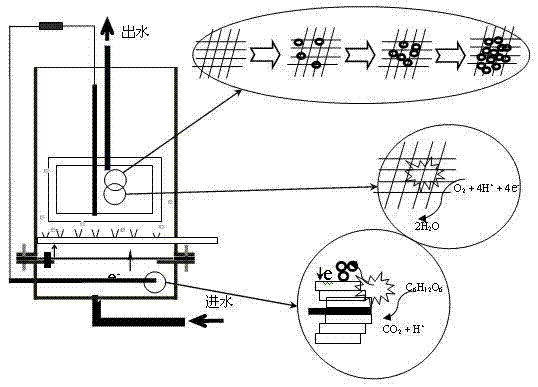

[0029] Embodiment 1: as figure 1 and figure 2As shown, the upflow electrochemical membrane bioreactor is composed of an anode chamber 1 , a cathode chamber 2 , a separation membrane 3 , a connecting pipe 4 , an external circuit 10 , an inlet pipe 11 and an outlet pipe 12 . The anode chamber 1 further comprises a graphite material filler 5 and an anode carbon rod 6, etc., the graphite material filler 5 is any one of graphite brush, graphite particles, graphite felt or other forms, and the cathode chamber 2 includes a membrane separation assembly 7, a cathode Carbon rod 8 and aeration tube 9, the aeration is provided by the aeration device, and the aeration tube 9 is located directly below the membrane separation module 7, which is convenient for scouring the membrane surface to reduce membrane pollution. The anode chamber 1, the cathode chamber 2 and the separation film 3 constitute the inner circuit of the MFC, which are connected with the external circuit 10 to form the who...

Embodiment 2

[0032] Using the device and method described in Example 1 to treat rural domestic sewage, the influent COD concentration is 307.6±15.7 mg / L, the ammonia nitrogen concentration is 24.2±2.4 mg / L; the hydraulic retention time of the anode chamber is 17 min, and the hydraulic retention time of the cathode chamber is 6.1 h. The membrane flux is 30 L / (m 2 h). The average removal rate of COD is 90.3%±1.8, the average removal rate of ammonia nitrogen is 98.5%±0.8, the turbidity of the effluent is less than 1NTU, the membrane cleaning cycle is maintained at more than 30d, and the maximum power density is 10.9 W / m 3 .

Embodiment 3

[0034] Using the device and method described in Example 1 to treat typical urban domestic sewage, the influent COD concentration is 644.2±21.5 mg / L, the ammonia nitrogen concentration is 35.2±2.6 mg / L; the hydraulic retention time of the anode chamber is 35 min, and the hydraulic retention time of the cathode chamber is 11.5 h , the membrane flux is 25 L / (m 2 h). The average removal rate of COD is 91.2%±1.6, the average removal rate of ammonia nitrogen is 99.1%±1.2, the turbidity of the effluent is less than 1NTU, the membrane cleaning cycle is maintained at more than 30d, and the maximum power density is 14.9 W / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com