Method for deeply treating and recycling coal gasification wastewater by preposed oxidization combined with microwaves

A technology of oxidation treatment and advanced treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

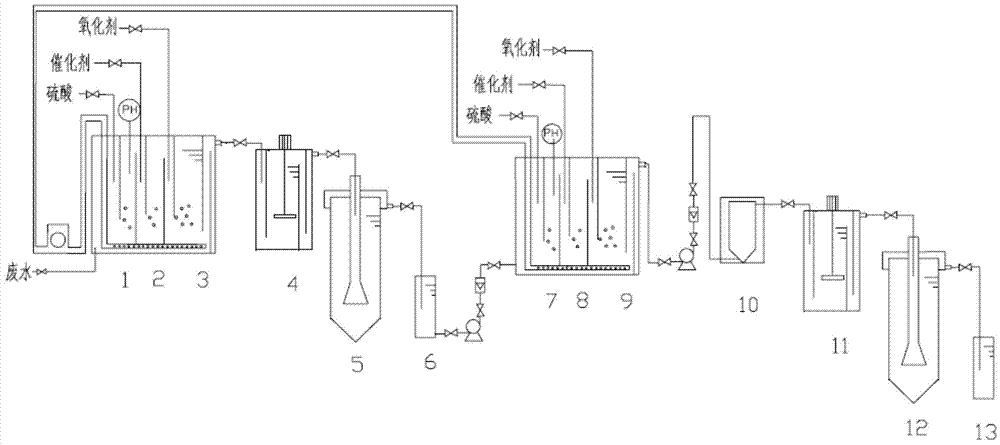

Method used

Image

Examples

Embodiment 1

[0049] The coal-gas wastewater after a certain biochemical process is treated by a method of pre-oxidation combined with microwave advanced treatment and reuse of coal-gas wastewater of the present invention. COD500mg / L, pH: 8.01 of biochemical coal gasification wastewater. First, carry out primary acidification reaction treatment, add sulfuric acid to adjust pH: 3.0, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after acidification is 350 mg / L; the effluent after primary acidification is added with 50 mg / L of ferrous sulfate Catalyzed reaction, reaction for 5 minutes, pH: 2.9; waste water after primary catalysis was added hydrogen peroxide 350 mg / L according to the ratio of hydrogen peroxide to waste water 1:1, and reacted for 80 minutes, pH: 2.9; waste water after primary oxidation was flocculated Reaction, add sodium hydroxide to adjust the pH of the wastewater: 9, react for 15 minutes, at this time, the COD of the coal gas wastewater after floc...

Embodiment 2

[0051] The coal-gas wastewater after a certain biochemical process is treated by a method of the present invention which combines pre-oxidation and microwave advanced treatment of coal-gas wastewater and reuses it. COD450mg / L, pH: 8.50 of biochemical coal gasification wastewater. Firstly, carry out primary acidification reaction treatment, add sulfuric acid to adjust pH: 3.3, and react for 15 minutes. At this time, the COD of coal gasification wastewater after acidification is 320mg / L; the effluent after primary acidification is added with ferrous sulfate 45mg / L Catalyzed reaction, reaction for 5 minutes, pH: 3.1; waste water after primary catalysis was added hydrogen peroxide 320mg / L according to the ratio of hydrogen peroxide to waste water 1:1, reaction for 80 minutes, pH: 3.1; waste water after primary oxidation was flocculated Reaction, add sodium hydroxide to adjust the pH of the wastewater: 8.5, react for 10 minutes, at this time, the COD of the coal-gas wastewater afte...

Embodiment 3

[0053] The coal-gas wastewater after a certain biochemical process is treated by a method of the present invention which combines pre-oxidation and microwave advanced treatment of coal-gas wastewater and reuses it. COD550mg / L, pH: 8.20 of biochemical coal gasification wastewater. First, carry out primary acidification reaction treatment, add sulfuric acid to adjust pH: 2.5, and react for 15 minutes. At this time, the COD of the coal-gas wastewater after acidification is 400mg / L; the effluent after primary acidification is added with 50mg / L of ferrous sulfate Catalyzed reaction, reaction for 10 minutes, pH: 2.4; waste water after primary catalysis was added hydrogen peroxide 600 mg / L according to the ratio of hydrogen peroxide to waste water 1.5:1, and reaction for 100 minutes, pH: 2.4; waste water after primary oxidation was flocculated Reaction, add sodium hydroxide to adjust the pH of the wastewater: 9, react for 15 minutes, at this time, the COD of the coal-gas wastewater a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com