Burnt agalmatolite brick and preparation method of burnt agalmatolite brick

A wax stone brick and technology of wax stone, applied in the field of refractory materials, can solve the problems of reducing the qualified rate and strength of finished products, affecting the durability of fired wax stone bricks, poor bonding and sintering performance, etc. The effect of shortening the control time and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~2

[0054] Using Taishun pyrophyllite raw ore and Shangyu pyrophyllite raw ore as main raw materials, the weight ratio of Taishun pyrophyllite raw ore and Shangyu pyrophyllite raw ore is 60:40, adding alumina and / or bentonite as a burning aid, and Add pulp waste liquid (that is, the aqueous solution of calcium lignosulfonate powder, the specific gravity of pulp waste liquid is about 1.14g / cm 3 ) were mixed, and the resulting mixture was press-molded under a pressure of 70MPa to obtain a semi-finished product, and then the semi-finished product was fired at a temperature of 1210°C for 144 hours to obtain a fired alabaster brick.

[0055] The particle size gradation in pyrophyllite raw ore is: 3~2mm30%; 2~1mm20%; 1~0mm30%; 0~0.088mm20%.

[0056] The average particle size of alumina used in all the examples of this application is ≤10um.

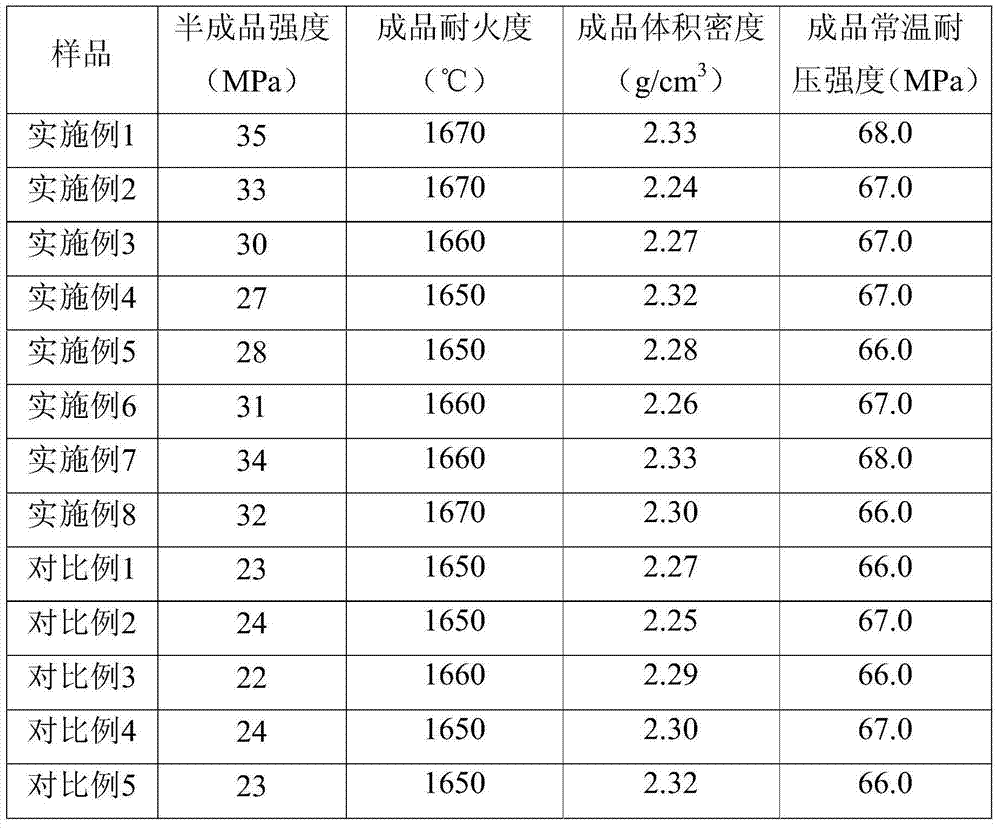

[0057] The proportioning ratio of each raw material in Examples 1~4 and Comparative Examples 1~2 is shown in Table 1, because the amount of alumin...

Embodiment 5~8 and comparative example 3~4

[0062] Using Taishun pyrophyllite raw ore and Changshan pyrophyllite raw ore as main raw materials, the weight ratio of Taishun pyrophyllite raw ore and Changshan pyrophyllite raw ore is 90:10, adding alumina and / or bentonite as a burning aid, and Add pulp waste liquid and mix, press the obtained mixture under 70MPa pressure to obtain a semi-finished product, and then burn the semi-finished product at 1300°C for 144 hours to obtain fired wax stone bricks.

[0063] The particle size gradation in pyrophyllite raw ore is: 3~2mm30%; 2~1mm25%; 1~0mm25%; 0~0.088mm20%.

[0064] The proportioning ratio of each raw material in Examples 5 to 8 and Comparative Examples 3 to 4 is shown in Table 2, and the SiO in the mixture obtained after mixing each raw material in Examples 5 to 8 and Comparative Examples 3 to 4 2 The weight percentage (based on the total weight of the mixture) is 83%, Al 2 o 3 The weight percentage is 13%.

[0065] Table 2

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com