Method for producing alpha-pinene from turpentine

A technology for turpentine and pinene, which is applied in the field of preparing alpha-pinene from turpentine, can solve the problems of waste of turpentine and the inability to fractionate other components at the same time, and achieves the advantages of reducing energy consumption, improving product value, improving production capacity and production value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

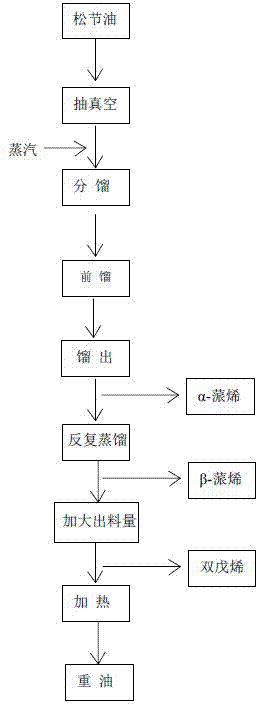

[0022] Such as figure 1 Shown, the preparation method that turpentine produces α-pinene adopts following process to carry out:

[0023] ①Feeding: transport turpentine oil to the fractionation tower kettle through pipelines, and the input amount is 5.0-6.0 tons;

[0024] ②Vacuumize: After feeding, vacuumize the reactor of the fractionation tower until the air pressure in the tower reaches -0.075MPa;

[0025] ③Front distillation: pass steam, heat the material in the kettle to above 95°C, while keeping the temperature at the top of the tower ≤ 50°C, and the temperature in the tower at 70-80°C; observe the outlet pipe at the top of the tower, and there is water-containing α-pinene distilled out Finally, control the discharge rate at 50L / h, and use this water-containing α-pinene as the fore run, and temporarily store it in the receiver tank;

[0026] ④ Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com