Preparation and refining method of pomalidomide

A technology of polilidomide and its refining method, which is applied in the field of preparation and refining of polilidomide, can solve the problems of low yield, low purity of the final product, and complicated preparation and operation, and achieve high reaction yield and large implementation Value and socio-economic benefits, the effect of reasonable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

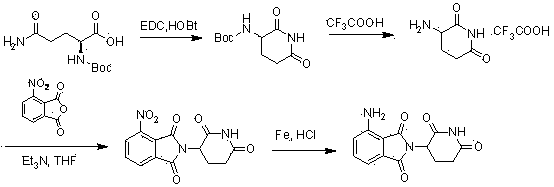

[0024] 3-Nitrophthalic anhydride (12.9g), α-aminoglutarimide hydrochloride (11.0g), acetonitrile (50ml), and acetic acid (10ml) were put into the reaction flask, heated and refluxed for 4 hours, Cool to room temperature, recover the solvent, add 50ml of water, precipitate a white solid, filter with suction, wash the solid with water, and dry under reduced pressure to obtain 16.7g, yield 83%, melting point > 200°C; 1 H NMR (DMSO- d6 ) δ: 11.17( s, 1H), 8.36 (d, J = 8.0 Hz, 1H), 8.25 (d, J = 8.0 Hz,1H), 8.10 (t, J = 7.5 Hz, 1H), 5.22 (dd, J = 13.0, 5.5 Hz, 1H ), 2.93-2.86 (m, 1H), 2.63-2.58 (m, 1H), 2.47-2.51 (m, 1H), 2.06-2.10 (m, 1H).

Embodiment 2

[0026] Put 3-nitrophthalic anhydride (12.9g), α-aminoglutarimide hydrochloride (11.0g), dioxane (50ml), and formic acid (20ml) into the reaction flask, heat up and reflux After 4 hours, cool to room temperature, recover the solvent, add 50ml of water, precipitate a white solid, filter with suction, wash the solid with water, and dry under reduced pressure to obtain 17.8g, yield 85%, melting point > 200°C;

Embodiment 3

[0028] Put 3-nitrophthalic anhydride (12.9g), α-aminoglutarimide hydrochloride (11.0g), toluene (60ml), p-toluenesulfonic acid (10g) into the reaction flask, and heat up to reflux After 8 hours, it was cooled to room temperature, the solvent was recovered, 150ml of water was added, a white solid was precipitated, filtered with suction, the solid was washed with water, and dried under reduced pressure to obtain 18.8g, yield 93.5%, melting point > 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com