A high-concentration organic waste liquid incineration equipment and process

A high-concentration organic waste liquid technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as high equipment maintenance costs, affecting heat transfer effects, and smaller flue diameters, and achieve the goal of reducing salt content Deposition and adhesion, large heating area, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following specific examples will further illustrate the present invention. It should be noted that the following is only a preferred example of the present invention and does not impose any limitation on the present invention.

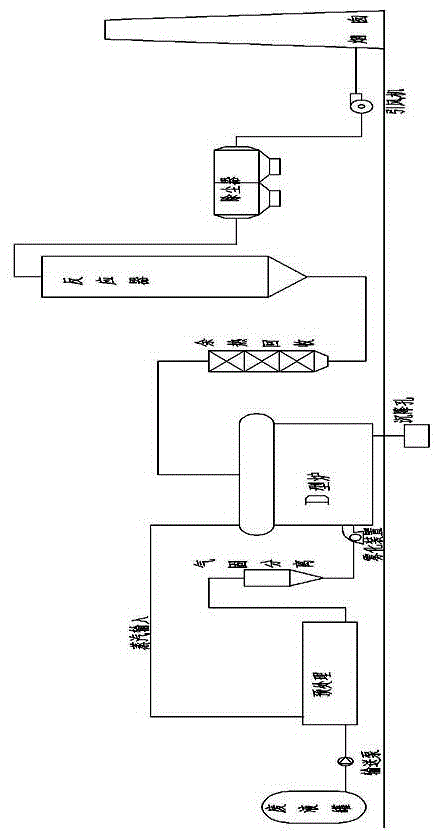

[0034] Such as figure 1 As shown, the high-concentration organic waste liquid incineration equipment described in the present invention includes a waste liquid tank, a delivery pump for extracting the liquid in the waste liquid tank to the preprocessor, a gas-solid separator connected to the preprocessor, a D-type furnace, and waste heat Recovery boiler, desulfurization and denitrification device, dust collector, chimney, among which the D-type furnace steam pipe is connected with the preprocessor, and the D-type road supplies steam to the preprocessor.

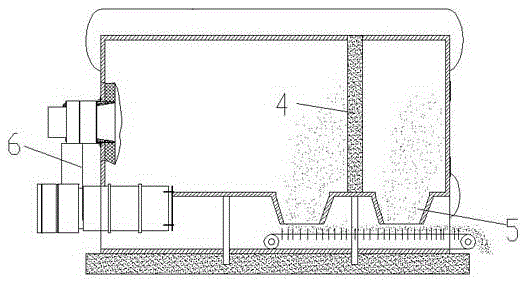

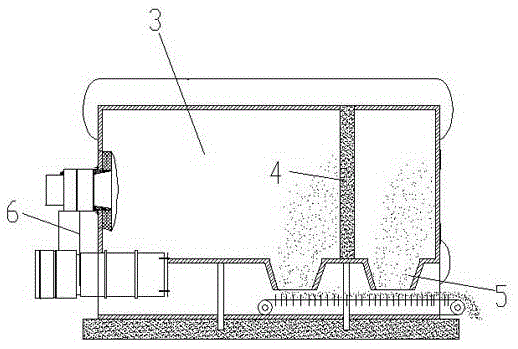

[0035] The drum of the D-type furnace is supported by the lower drum. The upper and lower drums are integrally connected by convection tube bundles and water wall expansion joints or weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com