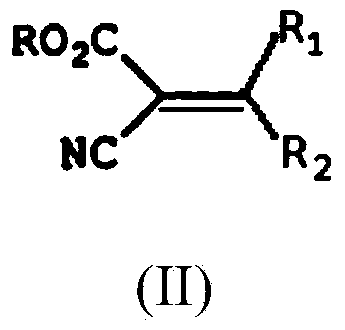

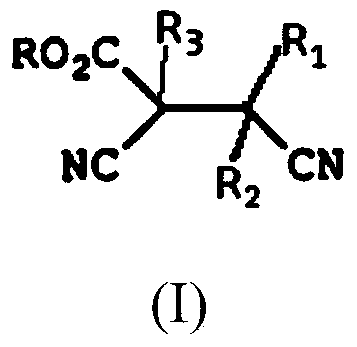

A process for preparation of dicyanocarboxylate derivatives

A technology of dicyanopropionate and cyano group, which is applied in the field of preparing dicyanocarboxylate derivatives, which can solve the problems of needing to be careful in the reaction, poor stability of formaldehyde cyanohydrin, decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0097]0.6 liter of absolute ethanol and 51.46 g of sodium cyanide (1.05 mol) were charged into a glass reactor equipped with a central vertical stirrer and a vertical condenser, followed by stirring at 30°C for 4 hours to obtain a slurry. Alternatively, 125.00 g of ethyl 2-cyano-2-propenoate (1 mole) was stabilized by dissolving methanesulfonic acid (3% by weight) in 100 ml of ethanol to give a stabilized ethyl 2-cyano-2-propenoate solution. A stable solution of ethyl 2-cyano-2-propenoate was injected into the slurry at 20°C-25°C over 2 hours to obtain a reaction mixture. The reaction mixture was further stirred at 20°C-25°C for 4 hours to obtain a reaction mass containing ethyl 2,3-dicyanopropionate sodium salt. The reaction was monitored by unreacted sodium cyanide. Then, the reaction mixture containing ethyl 2,3-dicyanopropionate sodium salt was cooled to 10°C, and dry hydrogen chloride gas was bubbled to neutralize the sodium salt of ethyl 2,3-dicyanopropionate . Then,...

example 2

[0099] 0.6 liters of anhydrous methanol and 51.46 g of sodium cyanide (1.05 mol) were charged into a glass reactor equipped with a central vertical stirrer and a vertical condenser, followed by stirring at 30°C for 4 hours to obtain a slurry. Alternatively, 125.00 g of ethyl 2-cyano-2-propenoate (1 mole) was stabilized by dissolving methanesulfonic acid (3% by weight) in 100 mL of methanol to give a stabilized ethyl 2-cyano-2-propenoate solution. A stable solution of ethyl 2-cyano-2-propenoate was injected into the slurry at 20°C-25°C over 2 hours to obtain a reaction mixture. The reaction mixture was further stirred at 20°C-25°C for 4 hours to obtain a reaction mass containing ethyl 2,3-dicyanopropionate sodium salt. The reaction was monitored by unreacted sodium cyanide. Then, the reaction mixture containing ethyl 2,3-dicyanopropionate sodium salt was cooled to 10°C, and dry hydrogen chloride gas was bubbled to neutralize the sodium salt of ethyl 2,3-dicyanopropionate . ...

example 3

[0101] 0.6 liters of anhydrous isopropanol and 51.46 g of sodium cyanide (1.05 mol) were charged into a glass reactor equipped with a central vertical stirrer and a vertical condenser, followed by stirring at 30°C for 4 hours to obtain a slurry. Alternatively, 125.00 g of ethyl 2-cyano-2-propenoate (1 mole) was stabilized by dissolving methanesulfonic acid (3% by weight) in 100 ml of isopropanol to give ethyl 2-cyano-2-propenoate stable solution. A stable solution of ethyl 2-cyano-2-propenoate was injected into the slurry at 20°C-25°C over 2 hours to obtain a reaction mixture. The reaction mixture was further stirred at 20°C-25°C for 4 hours to obtain a reaction mass containing ethyl 2,3-dicyanopropionate sodium salt. The reaction was monitored by unreacted sodium cyanide. Then, the reaction mixture containing ethyl 2,3-dicyanopropionate sodium salt was cooled to 10°C, and dry hydrogen chloride gas was bubbled to neutralize the sodium salt of ethyl 2,3-dicyanopropionate . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com