Preparation method for rose starch through vacuum freeze-drying

A vacuum freeze-drying and rose flower technology, which is applied in food preparation, food forming, food science, etc., can solve the problems of high heating temperature, loss of rose flower fragrance, and no rose fragrance, so as to extend the shelf life and reduce the Loss of volatile and heat-sensitive substances, non-oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

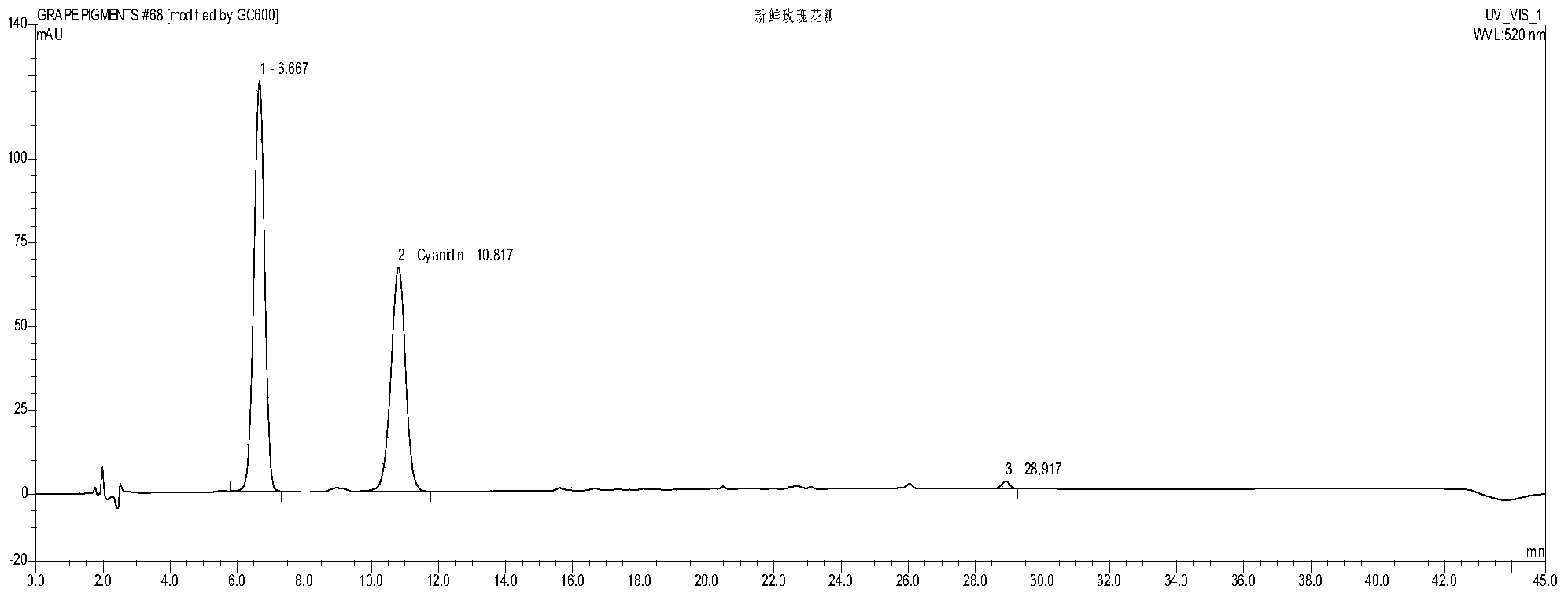

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of preparation method of vacuum freeze-dried rose pulp powder, its main feature is that the steps include:

[0023] a. Rose picking: use fresh rose petals picked within 24 hours, store in the shade, and the relative humidity of the environment is less than 50%;

[0024] b. Cleaning: Use clean water, rinse well, dry in the shade, refine the pulp without adding water at a temperature below 25°C and the relative humidity of the environment is less than 50%, the time: 10 minutes, the particle size is 80 mesh, and collect all the slurry into food in the container;

[0025] d. Vacuum freeze-drying: Put the rose slurry into the vacuum freeze-dryer, close the airtight door, turn on the vacuum pump switch and the freeze-dryer switch, evacuate to 15kPa, start refrigeration at the same time, and put the vacuum freeze-dryer within 2 hours. The temperature of the cold trap drops to -40°C and the holding time is 2 hours; the product is slowly heated through the ...

Embodiment 2

[0026] Embodiment 2: a kind of preparation method of vacuum freeze-dried rose pulp powder, its main feature is that the steps include:

[0027] a. Rose picking: use fresh rose petals picked within 24 hours, store in the shade, and the relative humidity of the environment is less than 50%;

[0028] b. Cleaning: Use clean water, rinse well, dry in the shade, refine the pulp without adding water at a temperature below 25°C and the relative humidity of the environment is less than 50%, the time: 25 minutes, the particle size is 120 mesh, and collect all the slurry into food in the container;

[0029] d. Vacuum freeze-drying: Put the rose slurry into the vacuum freeze-dryer, close the airtight door, turn on the vacuum pump switch and the freeze-dryer switch, vacuumize to 20kPa, start refrigeration at the same time, and freeze the vacuum freeze-dryer within 3 hours. The temperature of the cold trap is reduced to -50°C, and the holding time is 3 hours; the product is slowly heated t...

Embodiment 3

[0030] Embodiment 3: a kind of preparation method of vacuum freeze-dried rose pulp powder, its main feature is that the steps include:

[0031] a. Rose picking: use fresh rose petals picked within 24 hours, store in the shade, and the relative humidity of the environment is less than 50%;

[0032] b. Cleaning: Use clean water, rinse well, dry in the shade, refine the pulp without adding water at a temperature below 25°C and the relative humidity of the environment is less than 50%, the time: 50 minutes, the particle size is 150 mesh, and collect all the slurry into food in the container;

[0033] d. Vacuum freeze-drying: Put the rose slurry into the vacuum freeze-dryer, close the airtight door, turn on the vacuum pump switch and the freeze-dryer switch, evacuate to 25kPa, start refrigeration at the same time, and put the vacuum freeze-dryer within 4 hours. The temperature of the cold trap is reduced to -65°C, and the holding time is 0.5 hours; the product is slowly heated thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com