Low-carton secondary blockboard and method for manufacturing same

A blockboard, carbon secondary technology, applied in the direction of manufacturing tools, wood processing equipment, wooden veneer joints, etc., can solve the problems of waste of energy and raw material resources, complex blockboard, increased secondary energy consumption, etc. , to achieve the effects of energy saving, low carbon, low cost, saving glue, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

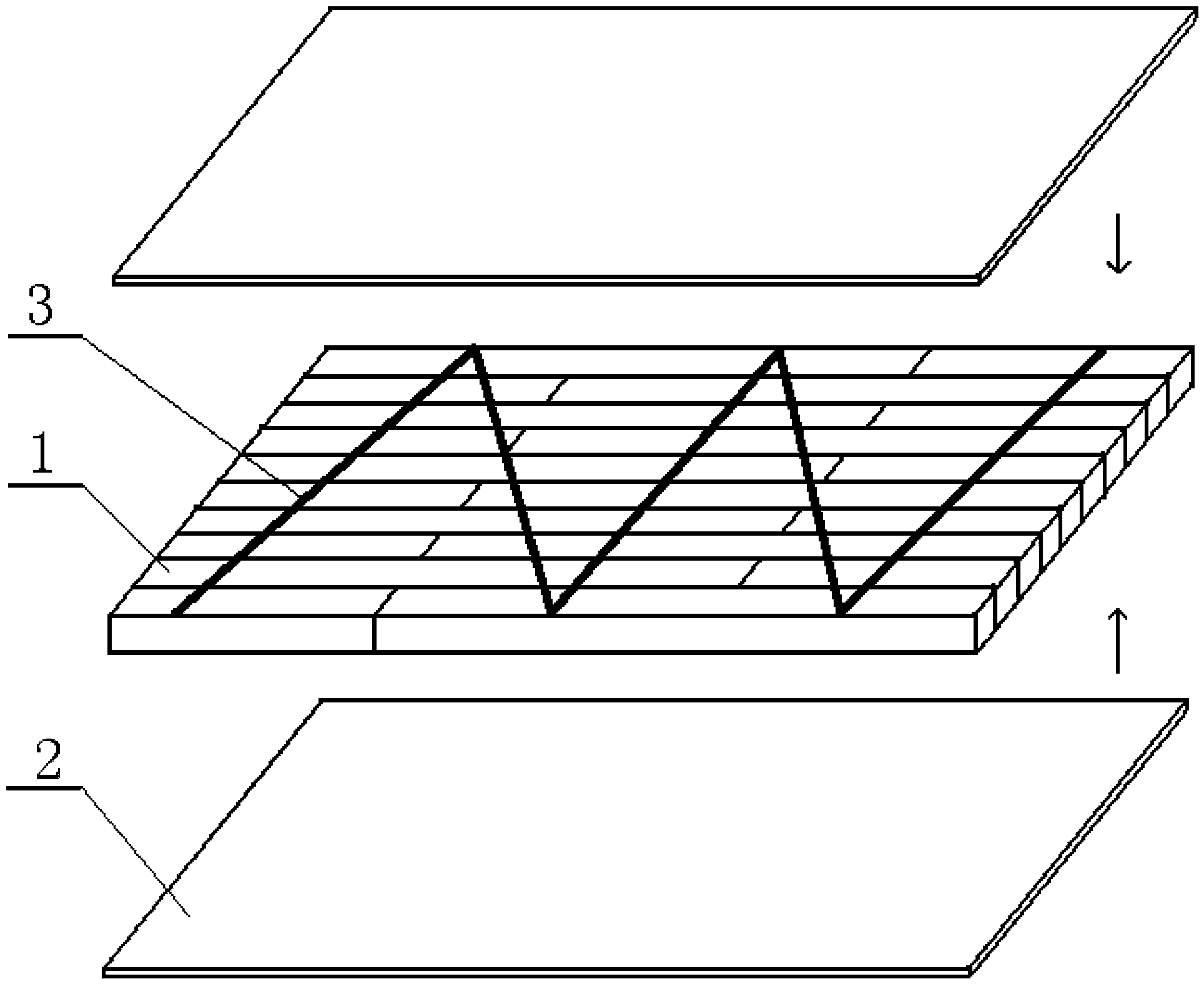

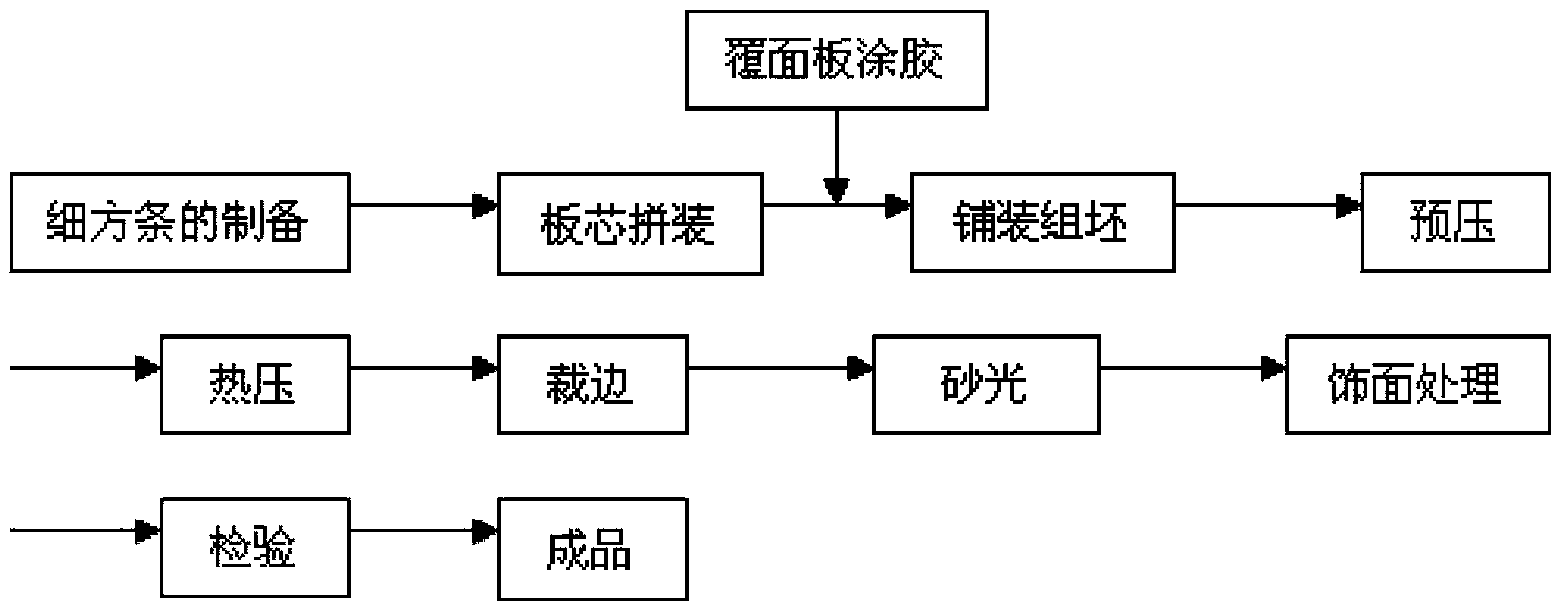

[0036] A general-purpose low-carbon secondary blockboard, mainly composed of a board core 1 and upper and lower cover panels 2; wherein, the board core 1 is mainly made of ordinary fiberboard, plywood or particleboard trimmings as raw materials The thin square strips made are spliced separately, and glued paper strips 3 are used to paste and fix the spliced thin square strips in an "N" shape on the spliced board surface. The upper and lower covering panels 2 adopt ordinary horizontal grain veneer.

Embodiment 2

[0038] A high-grade melamine low-carbon secondary blockboard for high-end purposes, mainly composed of a board core 1 and upper and lower cover panels 2; wherein, the board core 1 is mainly made of ordinary fiberboard, plywood or particleboard trimmings The thin square strips made of raw materials are spliced separately, and glued paper strips 3 are used to paste and fix the spliced thin square strips in an "N" shape on the spliced board surface. The upper and lower covering panels 2 adopt melamine veneer panels.

Embodiment 3

[0040] A high-grade flame-retardant melamine low-carbon secondary blockboard for high-end purposes, mainly composed of a core 1 and upper and lower cover panels 2; wherein, the core 1 is mainly composed of trimmings of flame-retardant fiberboard Thin square strips made of raw materials are spliced, and adhesive tape strips 3 are used to paste and fix the spliced thin square strips in an "N" shape on the spliced board surface. The splicing mode of the thin square strips is dislocation splicing. The upper and lower covering panels 2 adopt melamine veneer panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com