Porous polyimide composite retainer tube blank pre-heating, limiting and pressing process

A technology of polyimide and cage, which is applied in the field of preheating limit pressing process of porous polyimide composite cage tube billet, which can solve the problems of low tensile strength, stress cracking tube billet, large hole diameter and porosity, etc. problem, to achieve the effect of improving batch stability, improving production efficiency, and friction coefficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

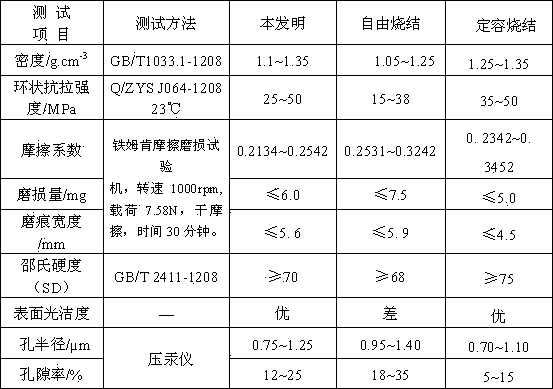

[0027] The present invention is a preheating limit pressing process for a porous polyimide composite cage tube blank. The process uses polyimide as the base material, and adds polytetrafluoroethylene solid lubricant to carry out preheating limit pressing and sintering. The tubular blank for the cage is produced, the method is simple and practical, the loss of the mold is reduced, and it can effectively solve the problem of loose texture, low tensile strength, large pore diameter and porosity of the product when the molding pressure is small during the free sintering process; the product is prone to stress when the molding pressure is high Cracking and poor consistency of material properties between tube blanks. The batch stability of the performance of the tube blank material prepared by the present invention can be greatly improved, such as oil content, porosity, pore size, density, mechanical properties and friction properties, and the production efficiency and quality are gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com