Alloyed zinc aluminum magnesium alloy coated steel plate and production method thereof

A technology of coated steel sheet and production method, which is applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems that have not yet been studied on the alloying of zinc-aluminum-magnesium coatings, achieve excellent formability and increase corrosion resistance , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

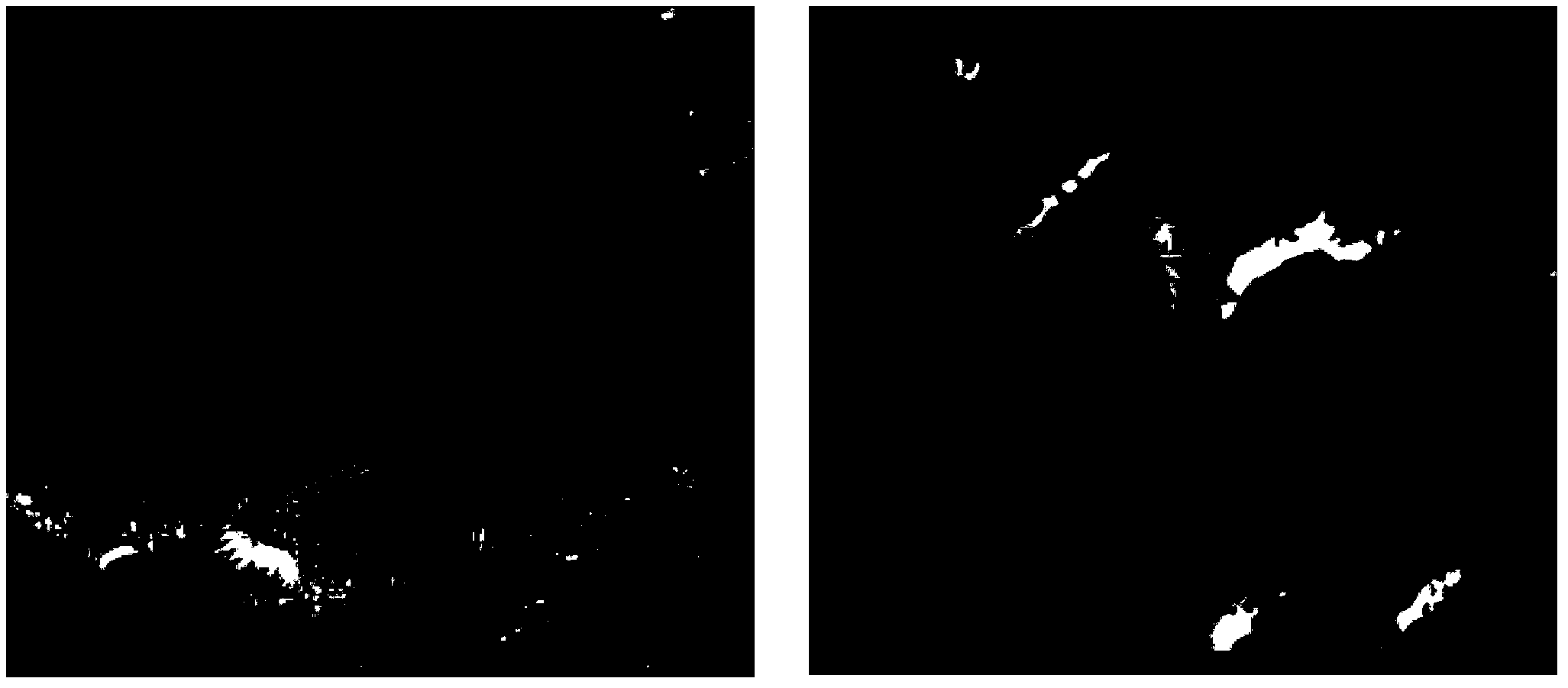

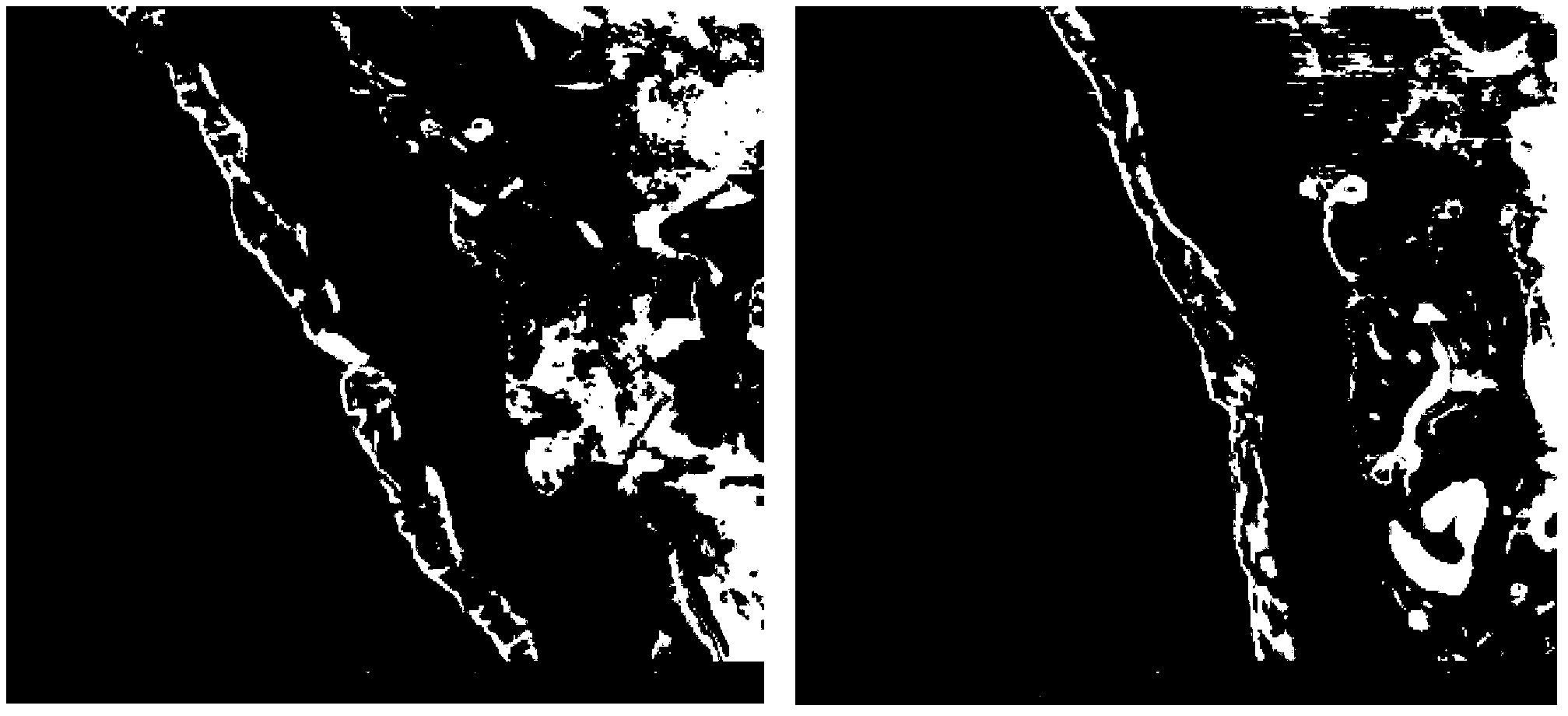

Image

Examples

Embodiment 1

[0026] Alloyed zinc-aluminum-magnesium coated steel sheet with excellent formability and production method thereof

[0027] The chemical composition of the plating solution is Al: 6 wt%, Mg: 3 wt%, mixed rare earth 0.05 wt%, and the rest is Zn and unavoidable impurities.

[0028] Steel plate containing 10 vol %H 2 N 2 After annealing, dip into the plating solution, the temperature of the plating solution is 560°C, the temperature of the steel plate into the zinc pot is 530°C, and the dipping time of the steel plate in the plating solution is 2s.

[0029] After plating, the steel plate is cooled by an air knife, the cooling rate is 30°C / s, and the strip speed is 100m / min.

[0030] After being cooled by an air knife, the zinc-aluminum-magnesium steel plate enters the alloying furnace, the alloying temperature is 550°C, the alloying time is 10s, and then the steel plate is cooled at a rate of 30°C / s.

[0031] The content of Fe in the coating is 2.2wt%, Al content 9.3wt%, Mg co...

Embodiment 2

[0033] Alloyed zinc-aluminum-magnesium coated steel sheet with excellent formability and production method thereof

[0034] The chemical composition of the plating solution is Al: 3 wt%, Mg: 0.5 wt%, misch metal 0.03 wt%, and the rest are Zn and unavoidable impurities.

[0035] Steel plate containing 10 vol %H 2 N 2 After annealing, dip into the plating solution, the temperature of the plating solution is 580°C, the temperature of the steel plate into the zinc pot is 550°C, and the dipping time of the steel plate in the plating solution is 3s.

[0036] The steel plate is cooled by air knife after plating, the cooling rate is 20°C / s, and the strip speed is 100m / min.

[0037] After being cooled by an air knife, the zinc-aluminum-magnesium steel plate enters the alloying furnace, the alloying temperature is 530°C, the alloying time is 8s, and then the steel plate is cooled at a rate of 20°C / s.

[0038] The Fe content in the coating is 3.2wt%, Al content 5.8wt%, Mg content 1.66...

Embodiment 3

[0040] Alloyed zinc-aluminum-magnesium coated steel sheet with excellent formability and production method thereof

[0041] The chemical composition of the plating solution is Al: 1 wt%, Mg: 1 wt%, mixed rare earth 0.02 wt%, and the rest is Zn and unavoidable impurities.

[0042] Steel plate containing 5 vol %H 2 N 2 After annealing, dip into the plating solution, the temperature of the plating solution is 550°C, the temperature of the steel plate into the zinc pot is 540°C, and the dipping time of the steel plate in the plating solution is 2s.

[0043] The steel plate is cooled by air knife after plating, the cooling rate is 10°C / s, and the strip speed is 100m / min.

[0044] After being cooled by an air knife, the zinc-aluminum-magnesium steel plate enters the alloying furnace, the alloying temperature is 510°C, the alloying time is 6s, and then the steel plate is cooled at a rate of 30°C / s.

[0045] The content of Fe in the coating is 4.3wt%, Al content 3.6wt%, Mg content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com