Method for preparing spectrally pure ultrafine silver chloride

A silver chloride and spectrally pure technology, applied in the direction of silver halide, etc., can solve the problems that the samples to be tested cannot be mixed uniformly, difficult to purchase, and cannot be ground into powder, so as to achieve effective analysis and testing, shorten the synthesis cycle, and improve The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment Adopt the method of the present invention to prepare spectroscopically pure ultrafine silver chloride

[0033] Silver chloride was prepared from analytically pure silver nitrate (produced by Chongqing Reagent Factory, Shanghai Reagent Factory, and Chengdu Reagent Factory) with batch numbers P01, P02, and P03, respectively.

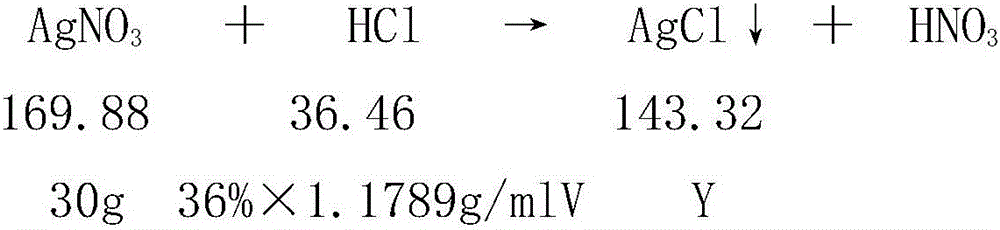

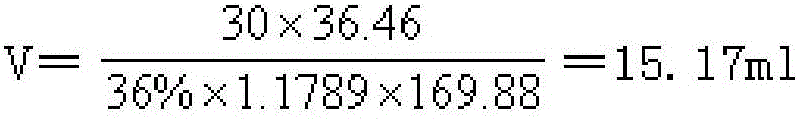

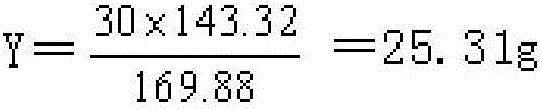

[0034]Weigh the above-mentioned 3 batches of silver nitrate 30g respectively in order and place them in three 500ml beakers, add 300ml distilled water to dissolve, filter to remove its water-insoluble matter, slowly add 32ml mixed solution in the filtrate respectively (the mixed solution is respectively: The mixed solution is prepared by mixing 36wt% hydrochloric acid solution, 95wt% ethanol solution, and ether at a volume ratio of 5:4.5:1; the mixed solution is prepared by mixing 36wt% hydrochloric acid solution, 95wt% ethanol solution, and ether at a volume ratio of 4: 3:1 mixed solution; the mixed liquid is prepared by mixing 36wt% hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com