Method for utilizing chicken manure to produce organic fertilizer

A technology of organic fertilizer and chicken manure, applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment and other directions, can solve the problems of increasing the production cost of products, difficult to completely decompose chicken manure, etc., and meet the requirements of reducing odor and growing conditions. The effect of low and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

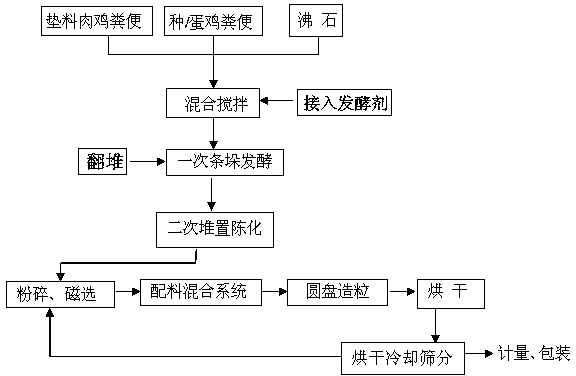

Method used

Image

Examples

Embodiment 1

[0052] Step ①, material mixing

[0053] The zeolite is crushed into zeolite powder with a particle size of 0.5mm, and the litter broiler manure (moisture content is 45%), breeder manure (moisture content is 75%) and zeolite powder are mixed evenly according to the weight ratio of 60:35:4, The pH of the mixture was 5.5, and the moisture content of the mixture was 60%.

[0054]Step ②, aerobic fermentation

[0055] The mixture and the microbial agent are piled up (stacks with a height of 1.2m and a width of 2m). After fermentation for 2 to 3 days, when the temperature of the pile rises to 65°C, turn the pile with a turning machine. When the temperature of the pile drops to 30 ℃, the aerobic fermentation ends, and the aerobic fermentation time is 9 to 12 days.

[0056] The weight of the microbial agent is 0.5% of the mixture. The colony-forming unit ratio of Aspergillus oryzae, high-temperature-resistant Bacillus subtilis and yeast in the microbial agent is 1:1:2, and the bacter...

Embodiment 2

[0062] Step ①, material mixing

[0063] The zeolite is crushed into zeolite powder with a particle size of 0.8mm, and the litter broiler manure (moisture content is 42%), breeder and laying hen manure (moisture content is 70%) and zeolite powder are in a weight ratio of 65:30:5.5 Mix well, the pH of the mixture is 6.5, and the moisture content of the mixture is 55%.

[0064] Step ②, aerobic fermentation

[0065] The mixture and the microbial agent are piled up (stacks with a height of 1.4m and a width of 2.5m). At 40°C, the aerobic fermentation ends, and the aerobic fermentation time is 9 to 12 days.

[0066] The weight of the microbial agent is 0.5% of the mixture. The colony-forming unit ratio of Aspergillus oryzae, high-temperature-resistant Bacillus subtilis and yeast in the microbial agent is 1:1:2, and the bacterial content in the microbial agent is greater than 0.5×10 6 pcs / g.

[0067] Step ③, stacking and aging

[0068] Move the materials after aerobic fermentatio...

Embodiment 3

[0072] Step ①, material mixing

[0073] The zeolite is crushed into zeolite powder with a particle size of 1.2mm, and the litter broiler manure (moisture content is 42%), laying hen manure (moisture content is 70%) and zeolite powder are mixed evenly according to the weight ratio of 70:25:7, The pH of the mixture was 7.0, and the moisture content of the mixture was 50%.

[0074] Step ②, aerobic fermentation

[0075] The mixture and the microbial agent are piled up (stacks with a height of 1.5m and a width of 2.2m). At 35°C, the aerobic fermentation ends, and the aerobic fermentation time is 9 to 12 days.

[0076] The weight of the microbial agent is 0.5% of the mixture. The colony-forming unit ratio of Aspergillus oryzae, high-temperature-resistant Bacillus subtilis and yeast in the microbial agent is 1:1:2, and the bacterial content in the microbial agent is greater than 0.5×10 6 pcs / g.

[0077] Step ③, stacking and aging

[0078] Move the materials after aerobic ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com