Preparation method of multi-copolymerized high salt tolerant acrylic resin

An acrylic resin, multi-copolymerization technology, applied in the field of high salt-resistant absorbent resin, can solve the problems of high labor intensity, slow salt water absorption, unfavorable environmental protection development, etc., achieve automatic operation, enhance rapid water absorption, reduce labor The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

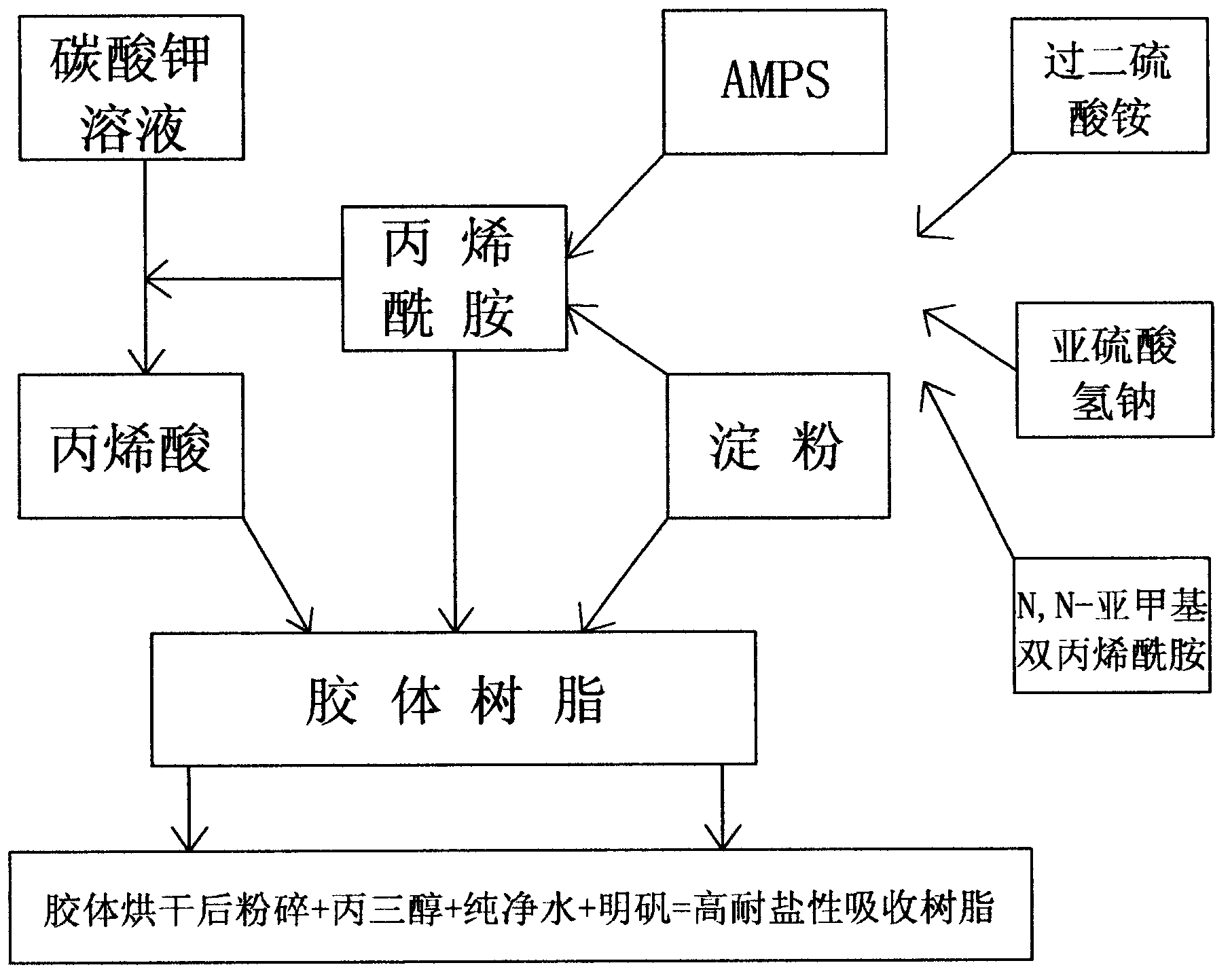

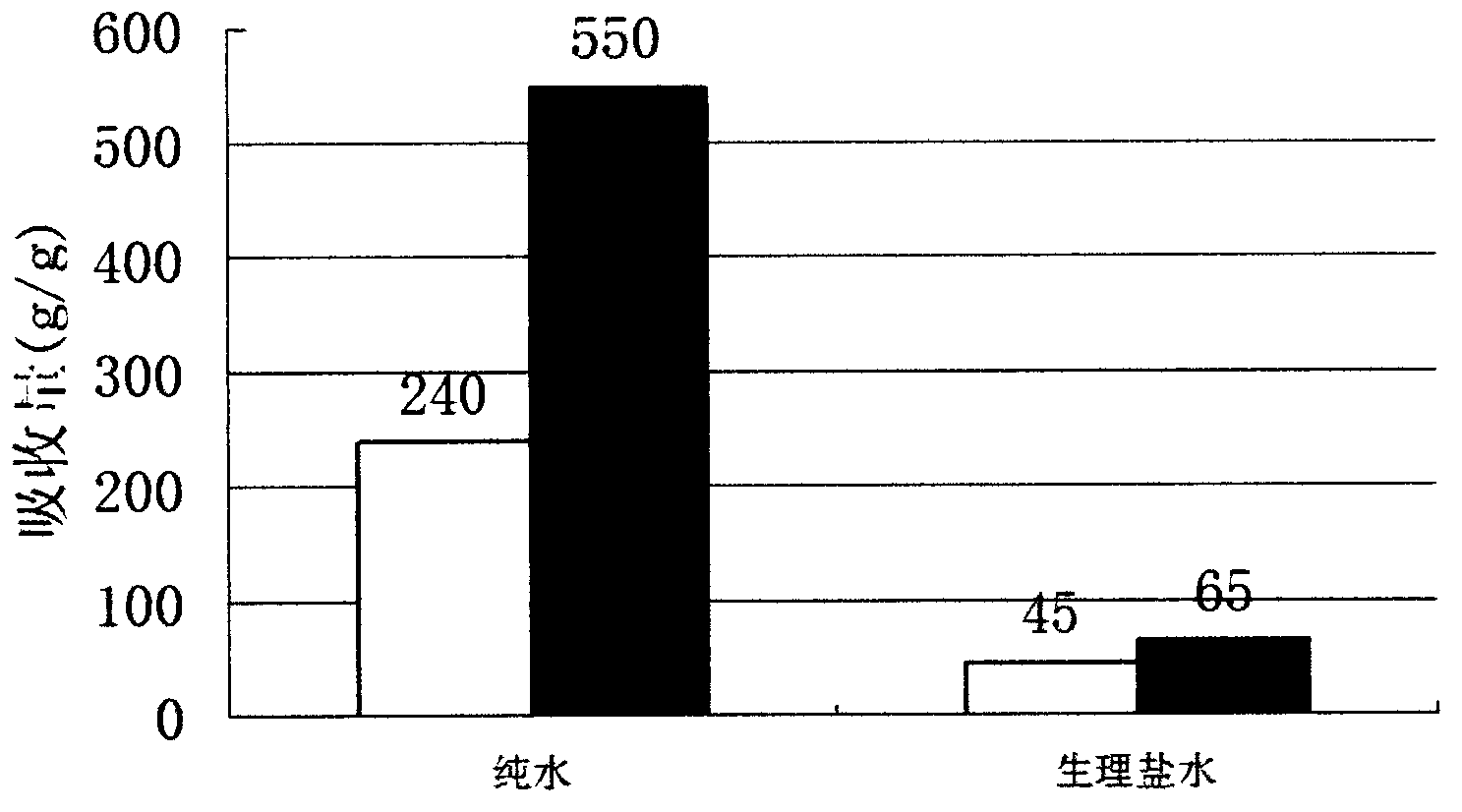

[0023] Such as figure 1 and figure 2 Shown, a kind of preparation method of multi-component copolymerized highly salt-resistant acrylic resin, it is high-purity acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, potassium carbonate, starch, acrylamide with mass fraction of 99.98% As raw materials, ammonium peroxodisulfate and sodium bisulfite are used as reducing system to initiate, and N, N-methylenebisacrylamide is used as crosslinking agent to synthesize multi-component copolymerized high salt-tolerant acrylic resin.

[0024] A method for preparing multi-component copolymerized high-salt-tolerant acrylic resin, which specifically includes the following steps: a. slowly adding 256 g of potassium carbonate solution into the high-purity acrylic acid solution, and stirring while pouring in until the addition is complete; b. Gently add 35g of 2-acrylamido-2-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com