Method for preventing excessive fusion of prereduced sinter

A technology of sintering ore and sintering material, which is applied in the field of preventing excessive melting of pre-reduced sintering ore. It can solve the problems of rising temperature of material layer, increasing carbon content, excessive melting of raw materials, etc., so as to improve the metallization rate and improve the utilization of fuel. efficiency, improving high temperature performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

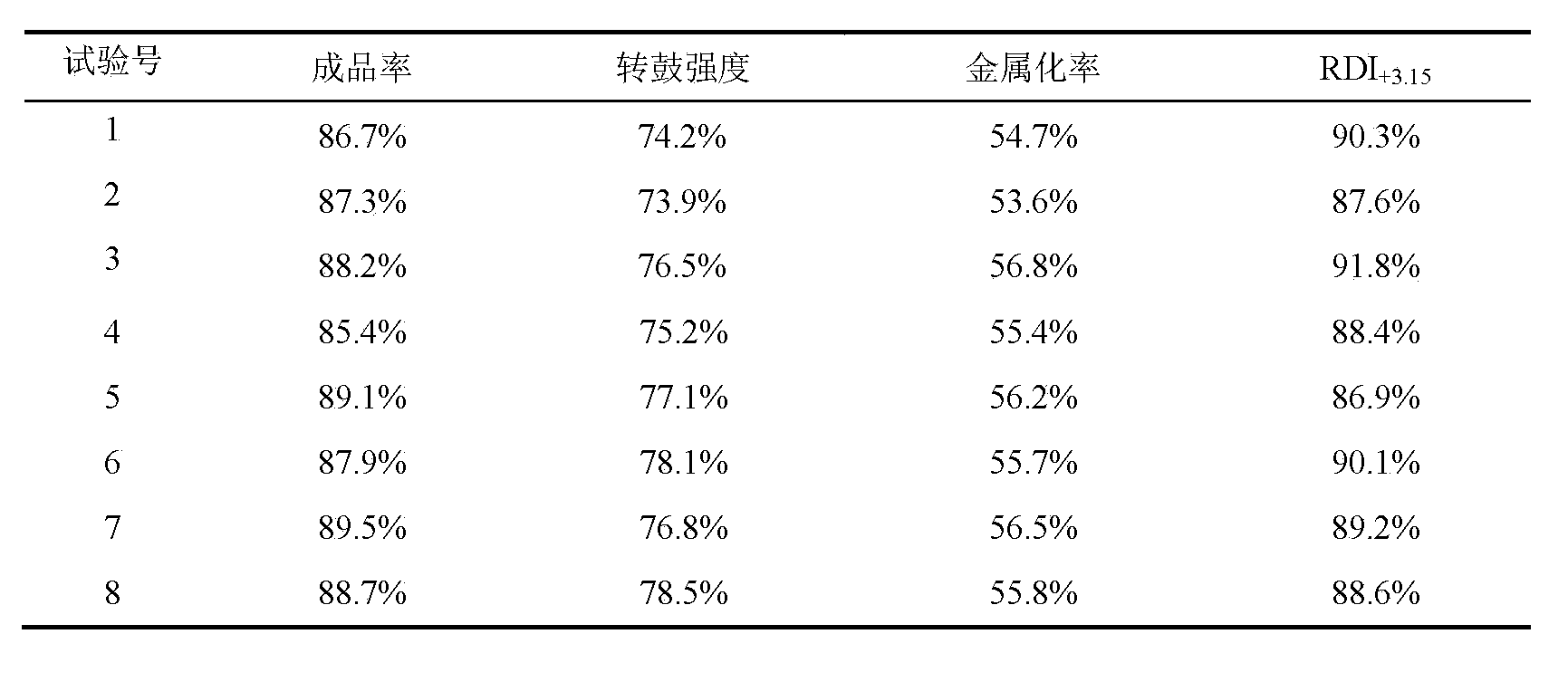

Examples

Embodiment 1

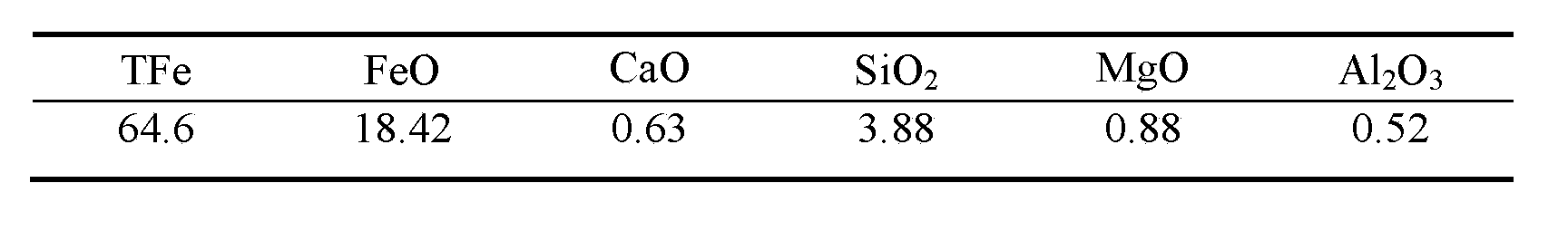

[0023] The pre-reduction sintering test was carried out with the mixed ore, and the composition of the mixed ore is shown in Table 1.

[0024] Table 1 Mixed iron ore composition / %

[0025]

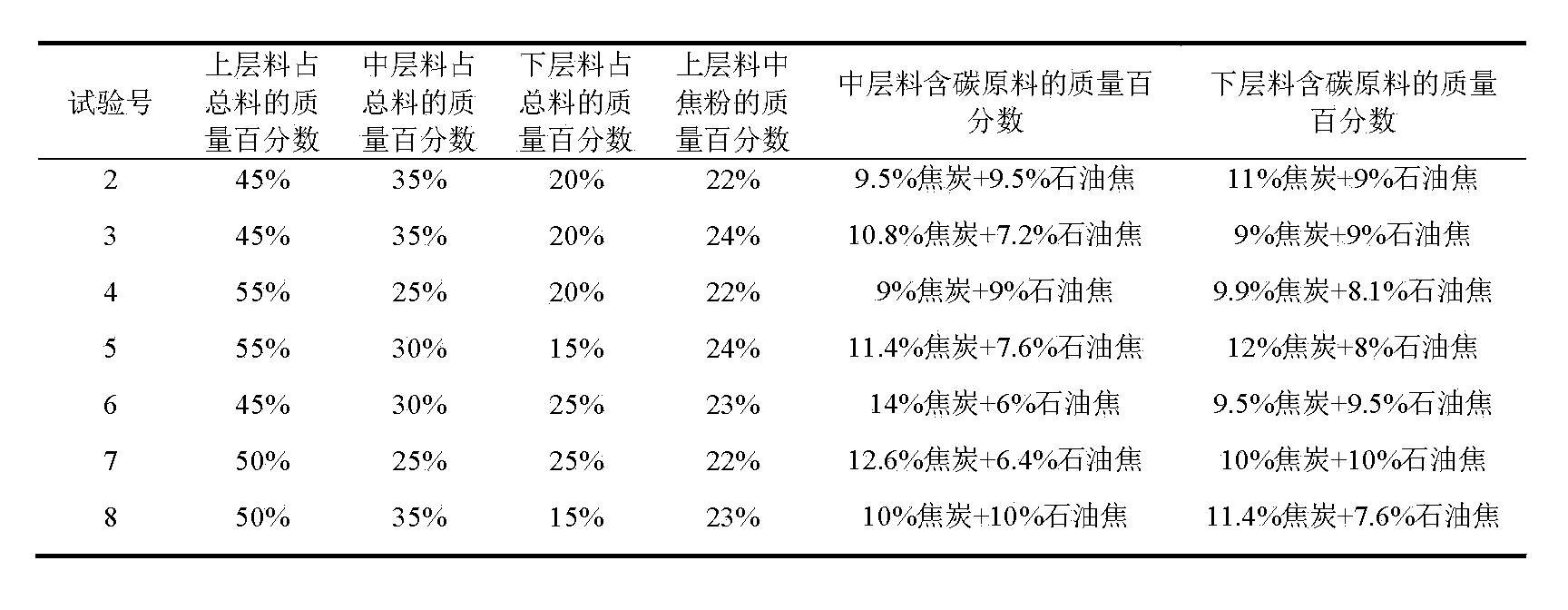

[0026] The sintered material layer is composed of three kinds of carbon-containing pellets with different particle sizes; the carbon-containing pellets are made of iron material, carbon-containing raw material and binder; the binary basicity of the sintered material layer is 1.9.

[0027] The sintered material is divided into upper, middle and lower layers. The carbon-containing raw material in the carbon-containing pellet composition of the upper layer is coke powder, the binder is sodium humate, and the mass percentage of sodium humate is 0.9%; the mass percentage of coke powder is 22% , and the rest are iron materials. The particle size of the carbon-containing pellets in the upper layer is 3mm~6mm, and this layer accounts for 45% of the total mass of the sintered material layer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com