Reaction chamber and thin film deposition equipment

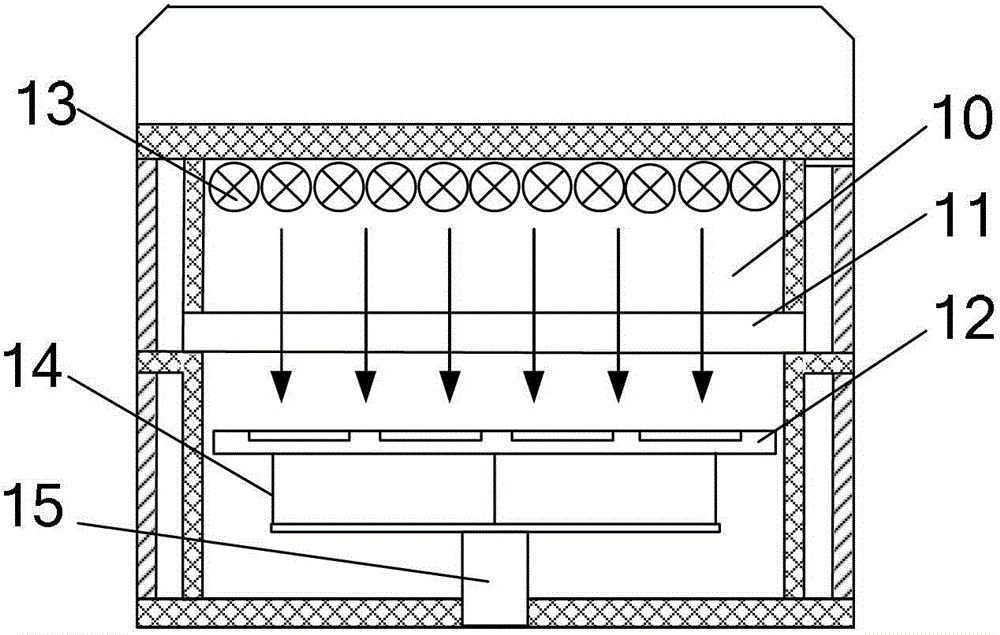

A reaction chamber and chamber technology, which are applied in the field of reaction chambers and thin film deposition equipment, can solve the problems of increasing the loss of radiated heat of a heating bulb 13, reducing the processing efficiency of thin film deposition equipment, reducing heating efficiency, etc., so as to improve the eddy current The effect of distribution, processing efficiency improvement, and heating efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the reaction chamber and thin film deposition equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

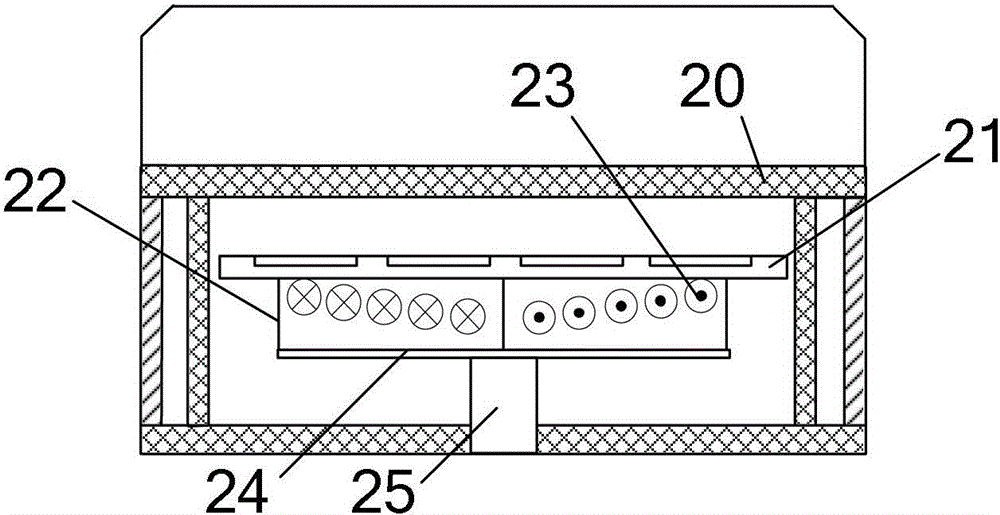

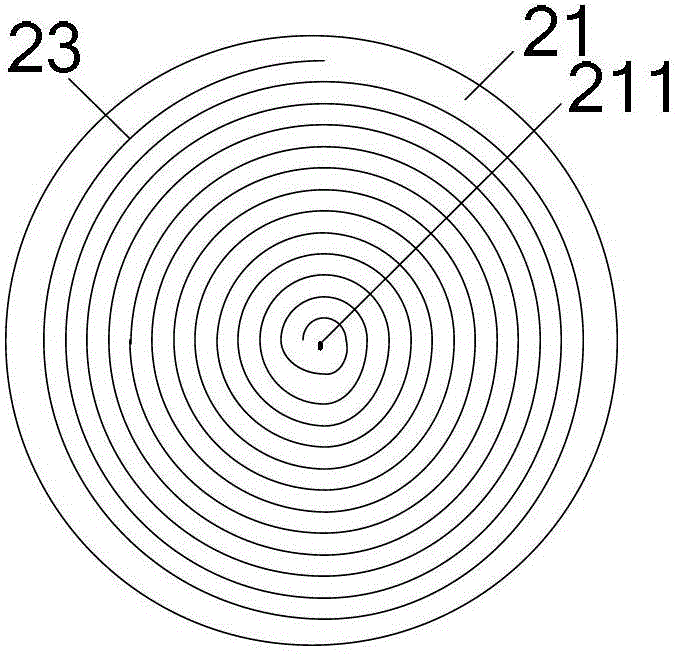

[0037] Figure 2a Schematic diagram of the structure of the reaction chamber provided by the first embodiment of the present invention. see Figure 2a , the reaction chamber includes a chamber body 20, a tray 21, a carrier, an induction coil 23 and an AC power supply (not shown in the figure). Wherein, the carrying part is disposed in the chamber body 20 for carrying the tray 21 . The tray 21 is used to carry the processed workpiece, which is made of magnetically permeable materials such as graphite, silicon carbide or magnetically permeable metal.

[0038] The induction coil 23 is disposed in the chamber body 20 and below the tray 21 , and is connected to an AC power source. When heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com