Device for processing food waste or sludge in low-temperature evaporation mode through solar flat sheet membranes

A solar panel and low-temperature evaporation technology, applied in solar thermal power generation, solar collectors using working fluid, solar thermal energy, etc., can solve problems such as high operating costs, difficult to run stably and up to standard, and difficult to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

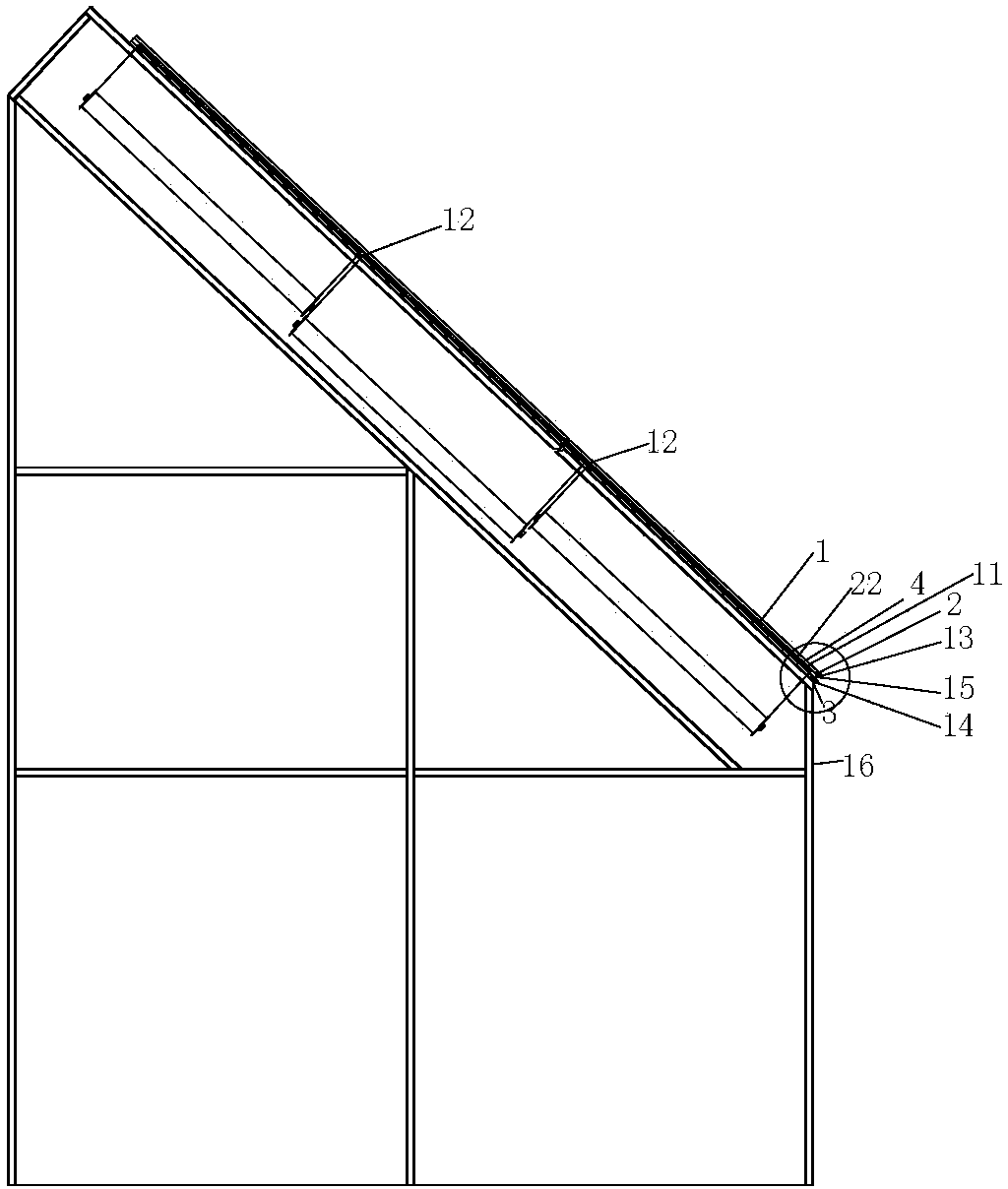

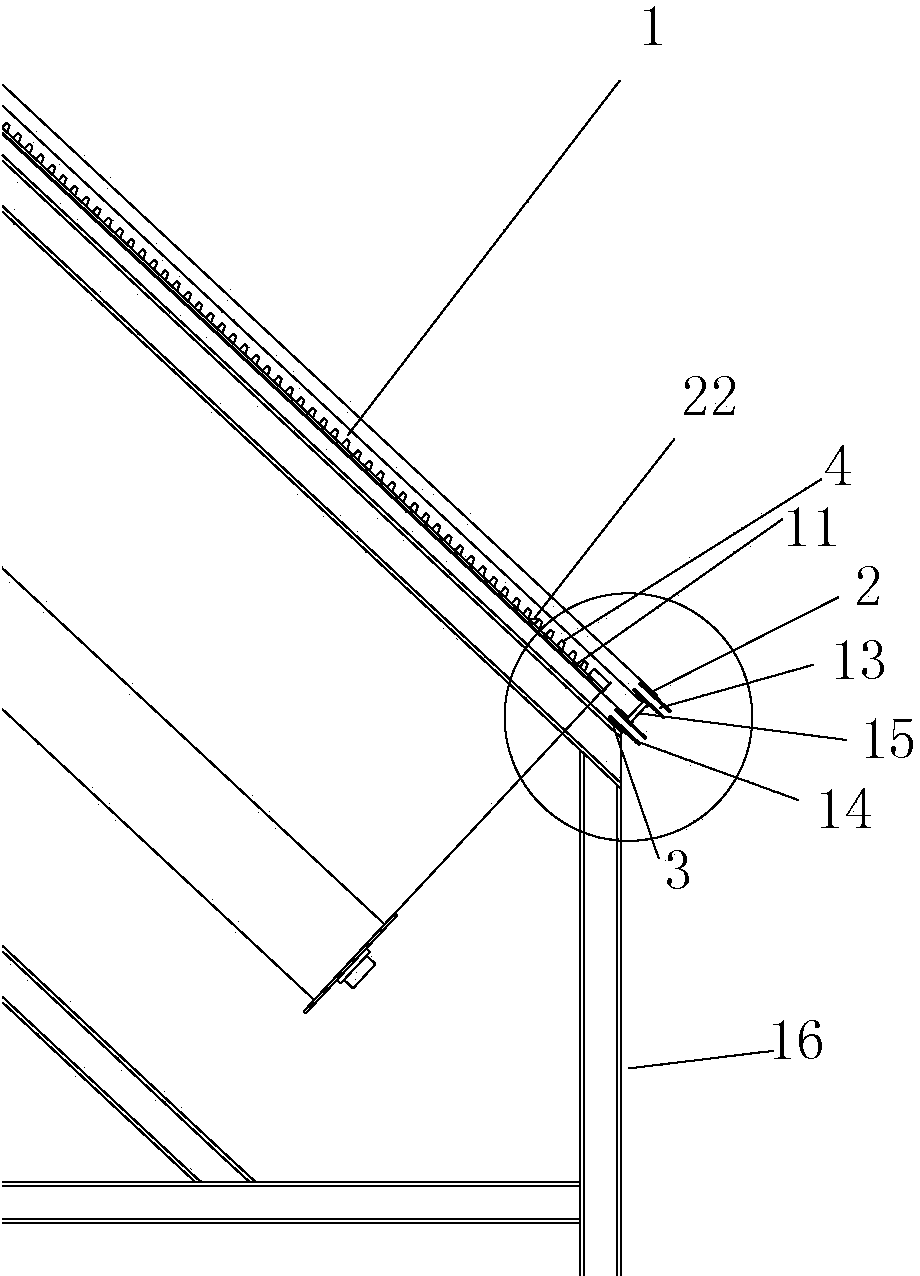

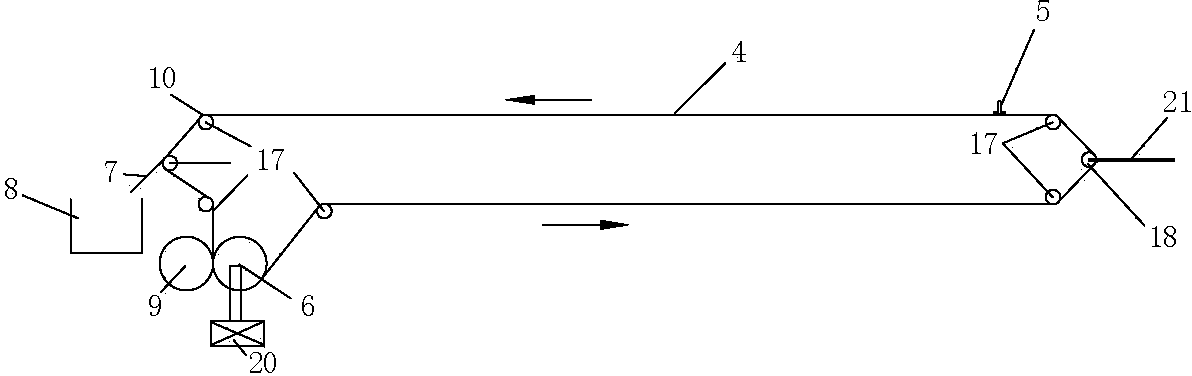

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as Figure 1-4 As shown, the present invention comprises an airtight box 1 made of an upper solar panel membrane 2 and a lower panel membrane 3, and the upper solar panel membrane 2 adopts a light-transmitting organic thin film or a light-transmitting inorganic thin plate Made, tightly connected with the frame around. The lower flat diaphragm 3 is airtightly connected with the surroundings of the frame using a transparent or opaque organic thin diaphragm or an inorganic thin plate. Concave-convex conveyer belt 4 is equipped with below described upper strata solar plate diaphragm 2, and the front of this conveyer belt is concavo-convex shape, and in the concavity, food waste or wet sludge 22 with higher moisture content is evenly filled by distributing device 5. The lower end of the upper solar panel diaphragm 2 is provided with an upper water outlet 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com