U-shaped heat pipe heat exchange element and u-shaped heat pipe heat exchanger integrated with electrostatic precipitator

A technology of electrostatic precipitator and heat pipe heat exchanger, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that direct heat pipes can only be applied, long production cycle, and only suitable for small heat exchangers, etc., to avoid The effect of unplanned forced shutdown, reduced sealing welding workload, and obvious heat transfer safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

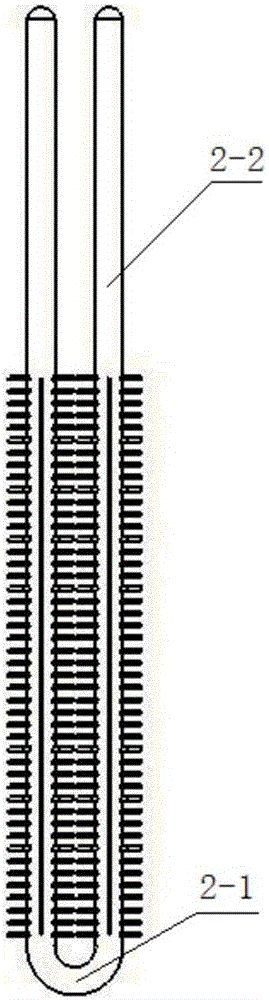

[0026] Such as figure 1 As shown, a U-shaped heat pipe heat exchange element of the present invention is composed of an integrally bent 180° elbow 2-1 and two continuously extending straight sections 2-2. Its extended heating surface adopts H-shaped, spiral, needle-shaped fins, plate-shaped fins or coupling fins.

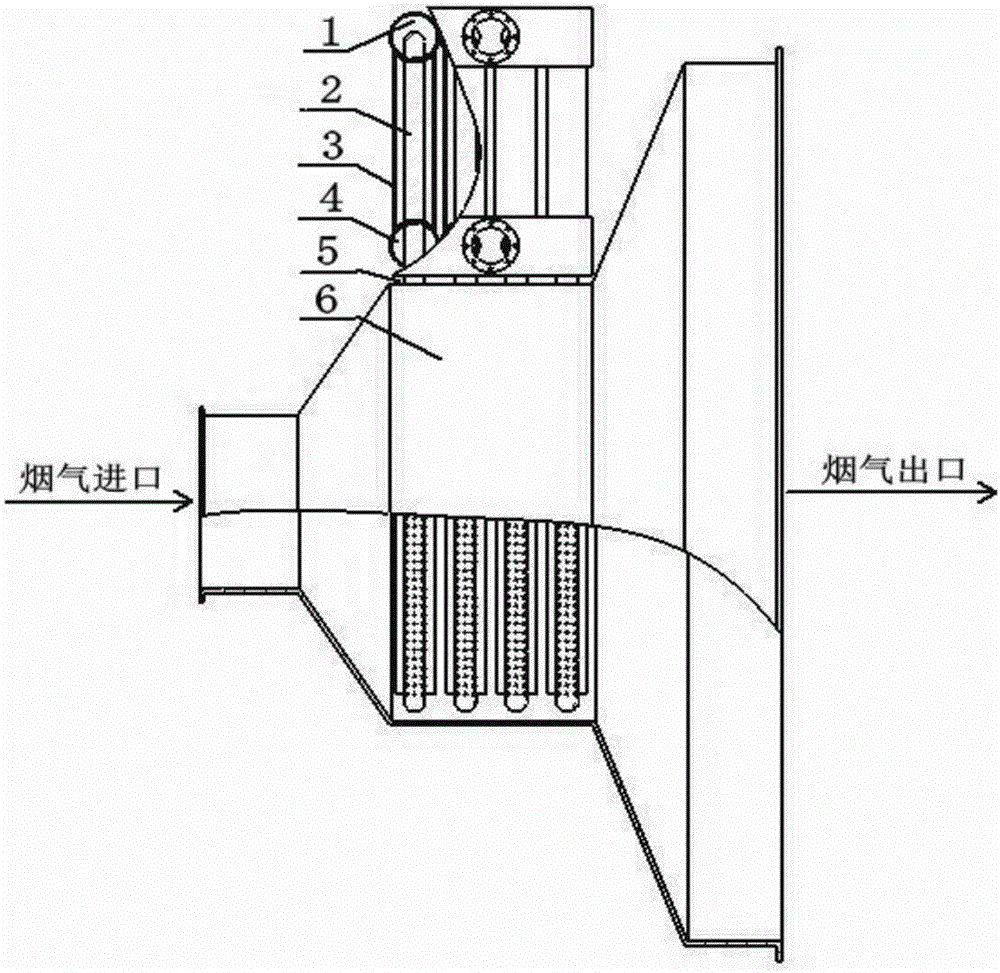

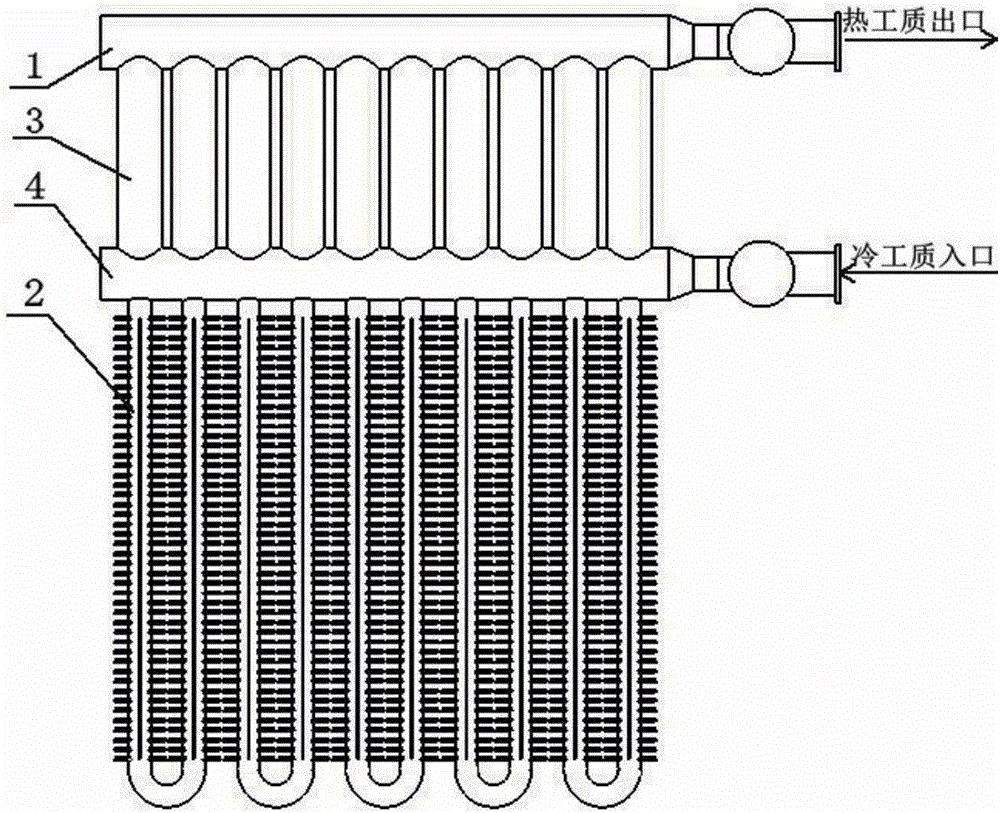

[0027] Such as figure 2 and image 3 As shown, the U-shaped heat pipe heat exchanger integrated with the electrostatic precipitator of the present invention includes a cooling working medium inlet header 4, a thermal working medium outlet header 1, and a cooling working medium inlet header 4 connected to a thermal working medium outlet header. The plurality of cooling medium casing pipes 3 of the box 1 also include the above-mentioned plurality of U-shaped heat pipe heat exchange elements as heat pipes 2, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com