Low-temperature hydraulic turbine closed type experimental system and test method

A technology of hydraulic turbine and experimental system, which is applied in the field of residual pressure recovery in the field of low-temperature liquefaction and low-temperature air separation, can solve the problem of not finding public information, and achieve the effects of low initial investment cost, easy implementation and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

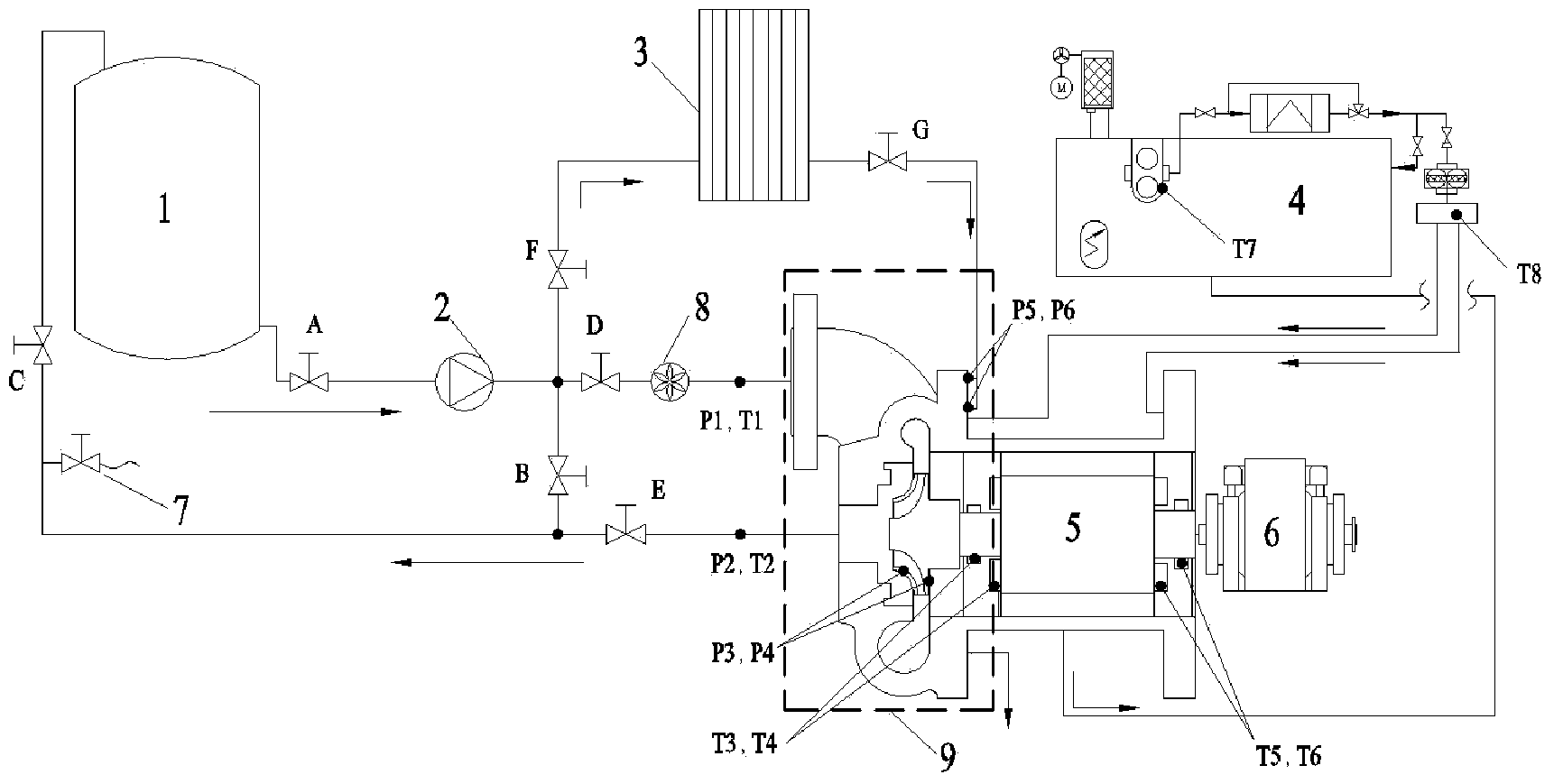

[0020] see figure 1 , the cryogenic hydraulic turbine closed experimental system of the present invention comprises a liquefied gas storage tank 1, a cryogenic pump 2, a vaporizer 3, an oil station 4, a hydraulic turbine 5 and a dynamometer 6; the liquefied gas storage tank 1 After the liquefied gas in the gas passes through the pipeline and the cryogenic pump 2 to increase the pressure, it enters the hydraulic turbine 5 through the pipeline all the way, and as the working medium of the hydraulic turbine 5 (Cryogenic Liquid Turbine), it is throttled down in the hydraulic turbine 5. The compressed liquefied gas returns to the liquefied gas storage tank 1 through the pipeline, and the other way enters the vaporizer 3 through the pipeline, where it is flashed into gas, and then introduced into the shaft seal seal chamber of the hydraulic turbine 5 through the pipeline, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com