High heat resistance type weldable polyesterimide enameled wire and production method thereof

A technology of polyesterimide and its production method, applied in the direction of conductors, conductor/cable insulation, insulated cables, etc., can solve the problem of not meeting the requirements of the self-priming magnetic water pump of coffee machines, long-term thermal life and low electrical insulation performance, and insufficiency Meet the requirements of direct welding of end wires and other issues, achieve the effects of improving heat resistance and electrical properties, simplifying production processes, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

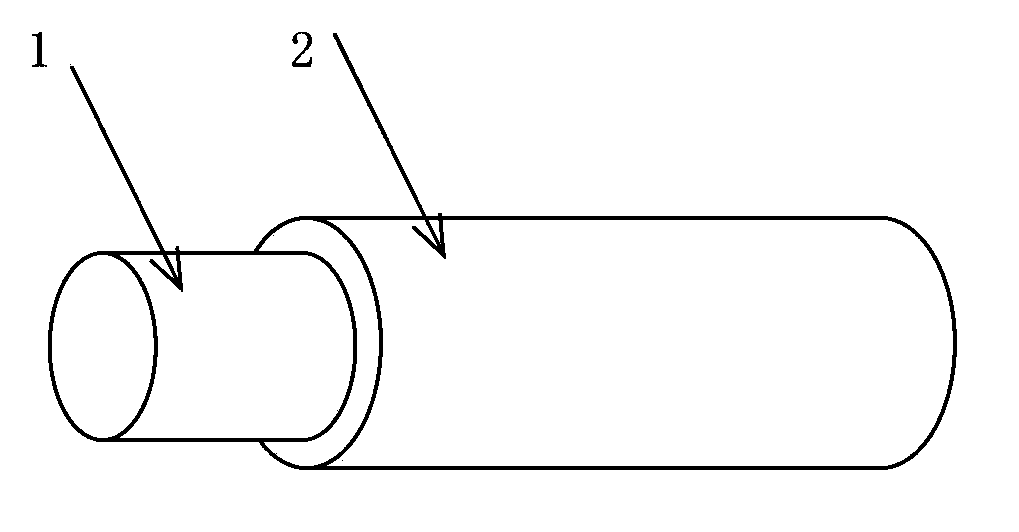

[0033] In one of the embodiments of the present invention, a kind of high heat resistance weldable polyesterimide enameled wire is provided, see figure 1 , The high heat-resistant solderable polyesterimide enameled wire includes a conductor core wire 1 and an insulating coating 2 wrapping the conductor core wire 1, and the diameter of the enameled wire is preferably 0.016-0.600 mm. The conductor core wire 1 of the present embodiment is a high-conductivity pure copper wire (a copper content of more than 99.95%), or, according to a special use occasion, the conductor core wire 1 can also be selected to have a higher conductivity copper alloy wire (including silver-copper alloy, tin-copper alloy, magnesium-copper all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com