Light emitting diode packaging structure

A technology for light-emitting diodes and packaging structures, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing light-emitting performance of light-emitting diode packages, decreasing light transmittance, and variability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

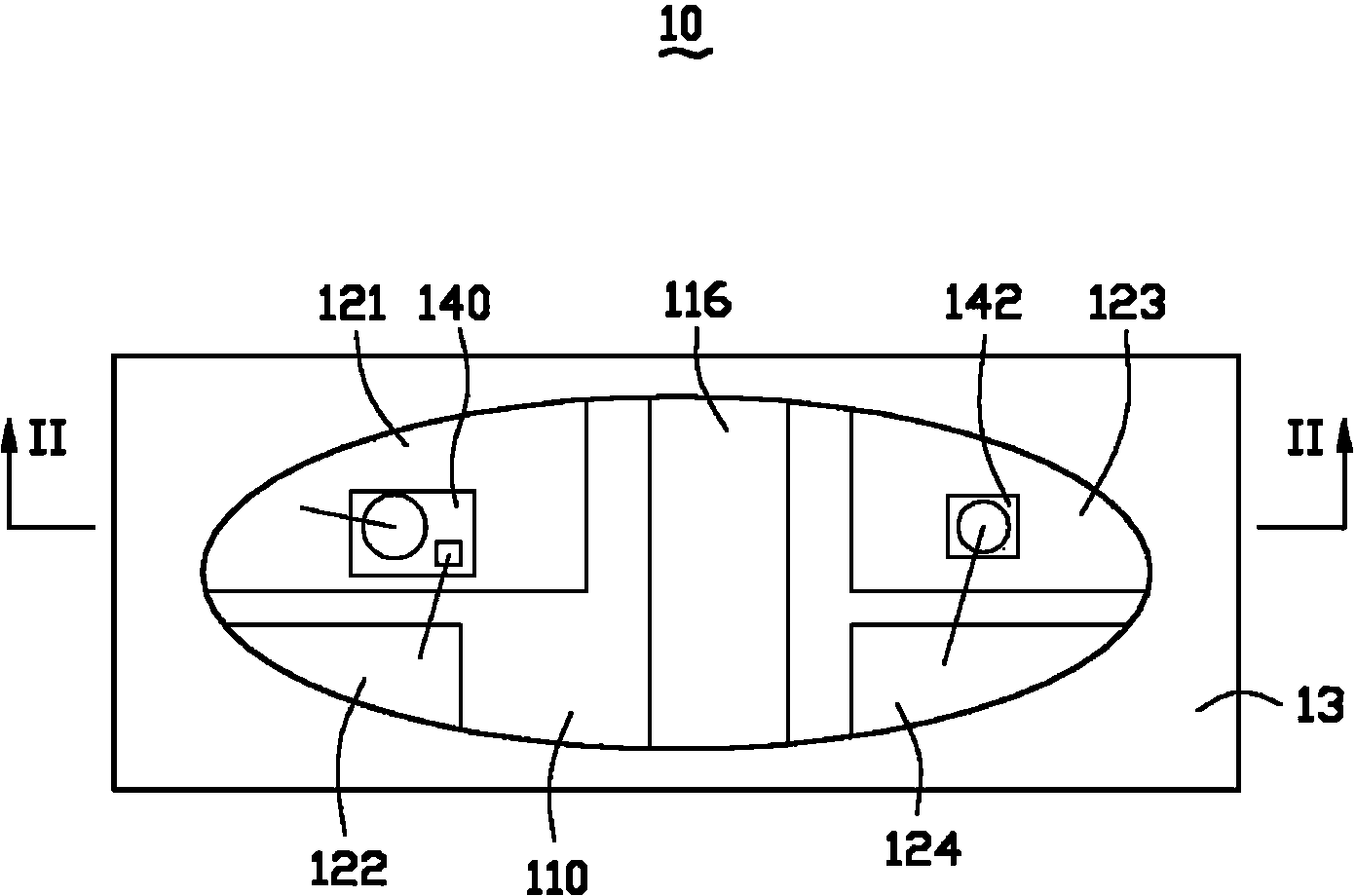

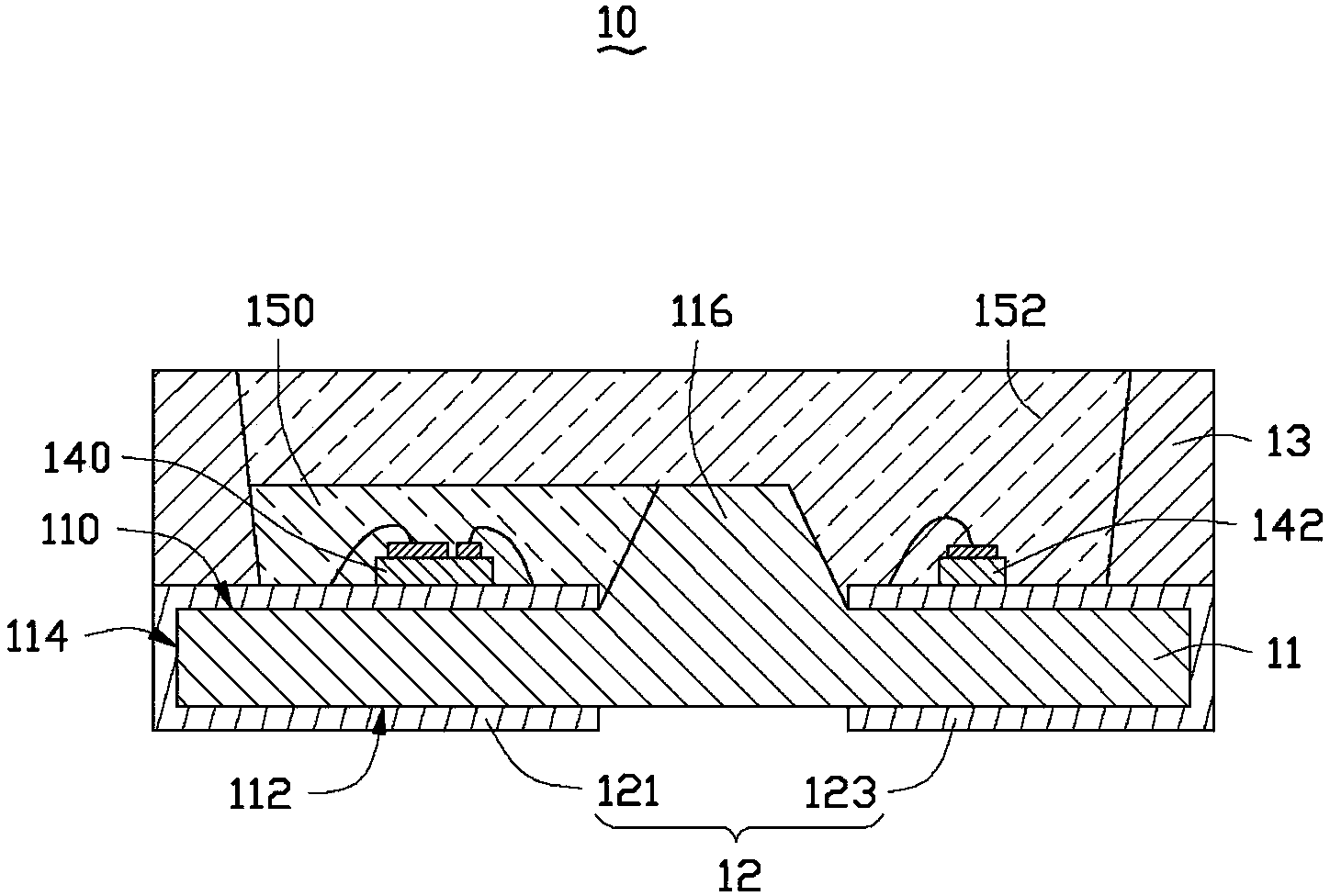

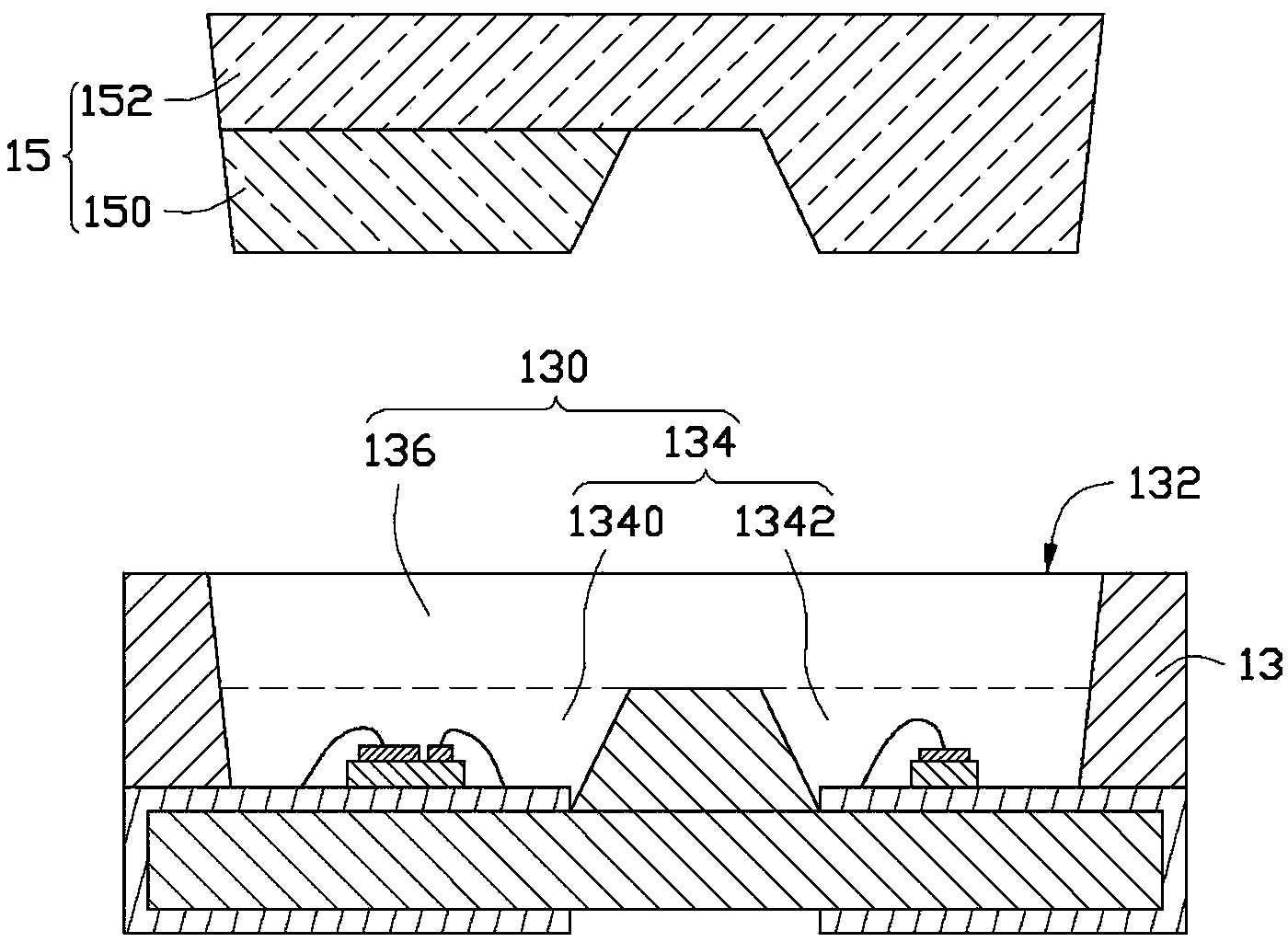

[0016] see figure 1 , figure 2 and image 3 , The light emitting diode package structure 10 provided by the first embodiment of the present invention includes a substrate 11 , electrodes 12 , reflective cups 13 , light emitting diode die 14 and a package body 15 .

[0017] The substrate 11 is an insulating substrate, and its material can be insulating materials such as sapphire (Sapphire) and silicon carbide (SiC). The substrate 11 includes a carrying surface 110 (ie figure 1 The upper surface of the substrate 11 shown), the bottom surface 112 opposite to the carrying surface 110, the side surface 114 located between the carrying surface 110 and the bottom surface 112 and connecting the carrying surface 110 and the bottom surface 112, and the side facing away from the bottom surface 112 from the carrying surface 110 The direction protruding stopper 116. The stopper 116 is located at the bottom of the reflection cup 13 . Preferably, the size of the stopper 116 gradually d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com