Resistive random access memory with high uniformity and manufacturing method thereof

A resistive memory and consistency technology, applied in static memory, digital memory information, information storage, etc., can solve the problems of increasing process complexity and difficulty in operation, and achieve the advantages of process integration, simple process steps, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

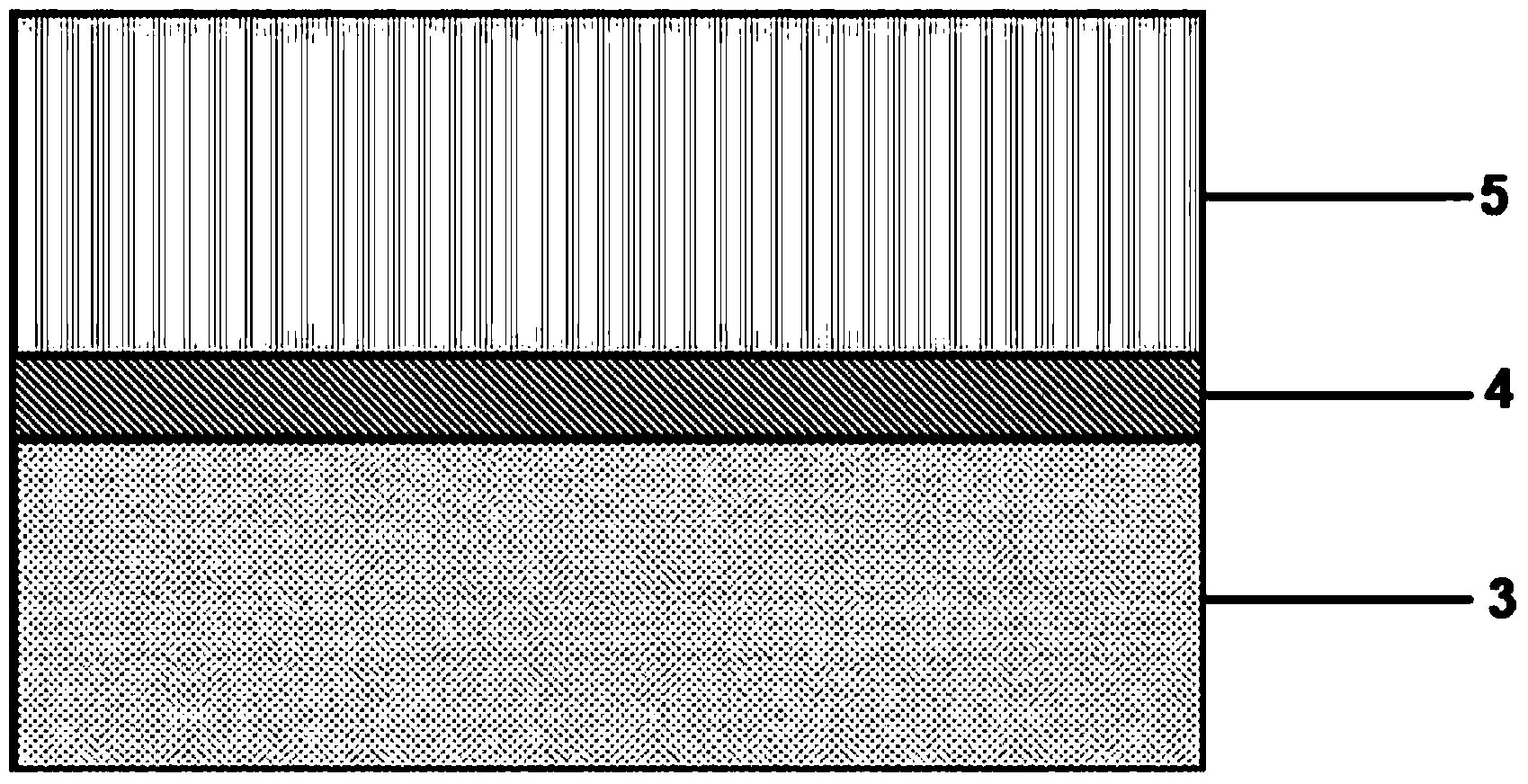

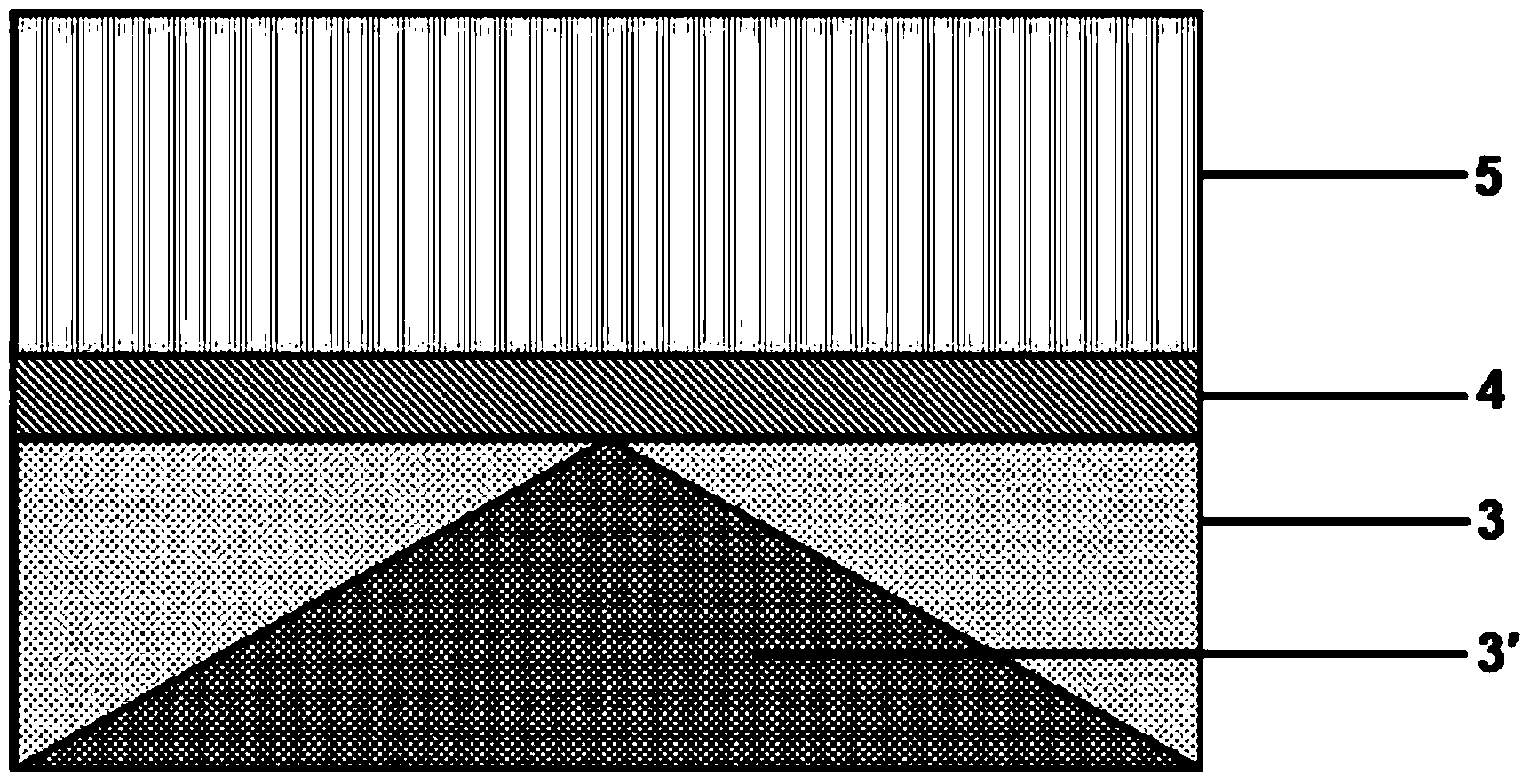

[0044] The resistive variable memory with high consistency of the present invention has a main structure such as figure 2 As shown, it includes a bottom electrode 3, a heavily doped peak region 3′, a resistive material thin film 4 and a top electrode 5, which are consistent with the mainstream resistive memory structure ( figure 1 ) is that the bottom electrode 3 uses a selectively heavily doped silicon substrate, and its heavily doped region forms a peak-like structure, so that the electric field is concentrated, and the resistive switching behavior occurs controllably at the peak.

[0045] The process of preparing the high-consistency RRAM according to the present invention is described as follows in conjunction with the accompanying drawings:

[0046] 1) Prepare the substrate. Select the substrate 1 opposite to the heavily doped polarity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com