Method for preparing jellyfish gonad hydrolyzed protein

A technology for hydrolyzing protein and gonads, which is applied in the field of preparing jellyfish gonad hydrolyzed proteins, which can solve the problems of no jellyfish gonad hydrolyzed proteins, etc., and achieve the effects of fast preparation speed, simple and convenient operation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation process steps of jellyfish gonad hydrolyzed protein are:

[0016] 1) Thaw the jellyfish gonads frozen at -20°C at -4°C, wash with water to remove impurities, and grind them with a high-speed tissue homogenizer.

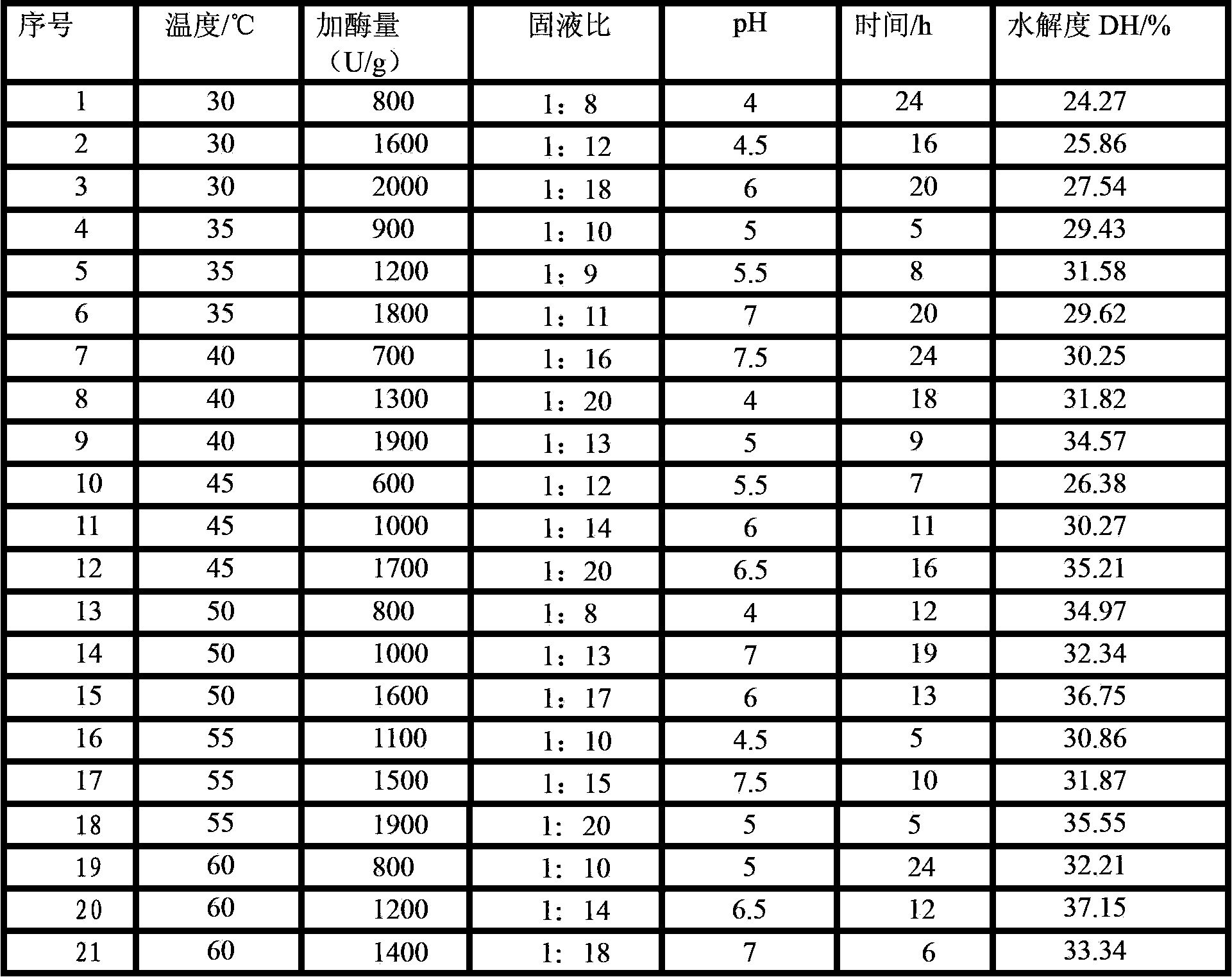

[0017] 2) Take a certain amount of minced jellyfish gonads and put them in a three-neck flask, place them in a water bath, stir them, and adjust the pH to 4-7.5 after reaching the predetermined temperature of 30-60°C. The ratio of enzyme to substrate jellyfish gonads is Add flavor protease at 600-2000U / g, and the solid-liquid ratio of jellyfish gonad and water is 1:8-20, and react for 2-24h.

[0018] 3) After enzymatic hydrolysis, heat the mixed slurry at 95-100°C for 10 minutes to inactivate flavor protease. After inactivation, the mixture was centrifuged at 4°C (4000-6000g, 8-15min), the supernatant was taken, and the degree of protein hydrolysis was determined by formaldehyde titration.

[0019] 4) Spray-dry the enzymatic hydrolysis concent...

Embodiment 1

[0021] 1) Thaw the jellyfish gonads frozen at -20°C at -4°C, wash with water to remove impurities, and grind them with a high-speed tissue homogenizer.

[0022] 2) Put the minced jellyfish gonads into a three-necked flask and place them in a water bath for stirring. After reaching the predetermined temperature of 30°C, adjust the pH to 4, and add flavor protease according to the ratio of enzyme to substrate jellyfish gonads at 1600U / g , The solid-liquid ratio of jellyfish gonads (g) to water (ml) is 1:8, react for 4 hours for enzymatic hydrolysis.

[0023] 3) After enzymatic hydrolysis, heat the mixed slurry at 95-100°C for 10 minutes to passivate the flavor protease and inactivate it. The mixture was centrifuged at 4°C (6000g, 10min), the supernatant was taken, and the degree of protein hydrolysis was determined to be 24.65% by formaldehyde titration.

[0024] 4) Concentrate the enzymatic solution of the jellyfish gonad after enzymolysis in step 2 to a concentration of 8-20%...

Embodiment 2

[0026] 1) Thaw the jellyfish gonads frozen at -20°C at -4°C, wash with water to remove impurities, and grind them with a high-speed tissue homogenizer.

[0027] 2) Put the minced jellyfish gonads into a three-necked flask and place them in a water bath for stirring. After reaching the predetermined temperature of 50°C, adjust the pH to 5.5, and add flavor protease according to the enzyme-to-bottom ratio of 1200U / g, and the solid-to-liquid ratio is 1 : 10, reaction 6h.

[0028] 3) After enzymatic hydrolysis, heat the mixed slurry at 95-100°C for 10 minutes to passivate flavor protease and inactivate it. The mixture was centrifuged at 4°C (5000g, 15min), the supernatant was taken, and the degree of protein hydrolysis was determined to be 38.23% by formaldehyde titration.

[0029] 4) Concentrate the enzymatic solution of the jellyfish gonads after enzymolysis in step 2 to a concentration of 8-20% of the hydrolyzed protein, and spray-dry the concentrated solution to obtain light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com