Gas-driving dispersive liquid-liquid microextraction method

A dispersion liquid-liquid and gas-driven technology, which is applied in the field of sample pretreatment in analytical chemistry, can solve the problems of uneven shaking force, difficulty in automation, poor reproducibility of analysis results, etc., and achieve the effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Determination of benzene, toluene, ethylbenzene and xylene (BTEX) content in environmental water samples by gas-driven dispersion liquid-liquid microextraction method of the present invention

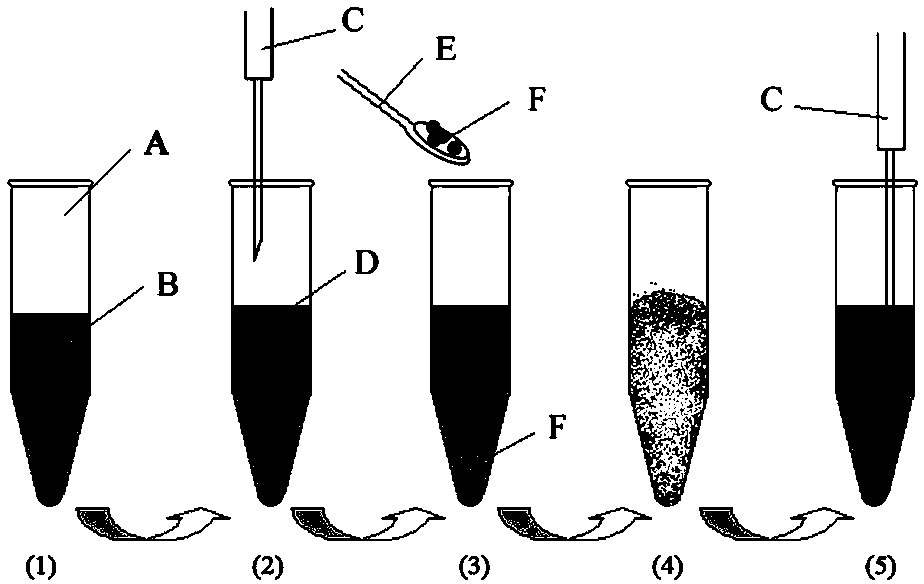

[0034] Add 2.3 g sodium bicarbonate to 100 mL BTEX standard solution or environmental water sample to prepare a water sample solution containing 2.3 % (w / v) sodium bicarbonate; then accurately pipette 3 mL of the above solution and place it in a 10 mL centrifuge tube Accurately add 300 μL of extractant ethyl acetate and 500 μL of dispersant methanol; quickly add 0.2-0.5 g of foaming agent ascorbic acid to the solution to generate a large number of bubbles instantly, and drive the extractant to fully disperse in the solution , let it stand for 5 min, and centrifuge at a speed of 300 rpm until the ethyl acetate and the water sample are separated; use a microsampler to take 1.00 μL of ethyl acetate and inject it into gas chromatography for analysis.

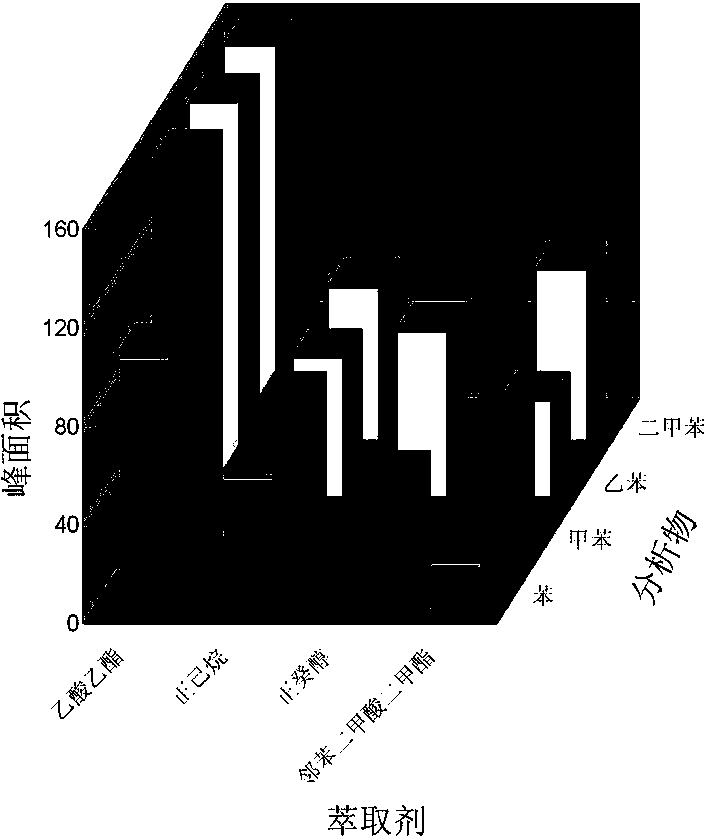

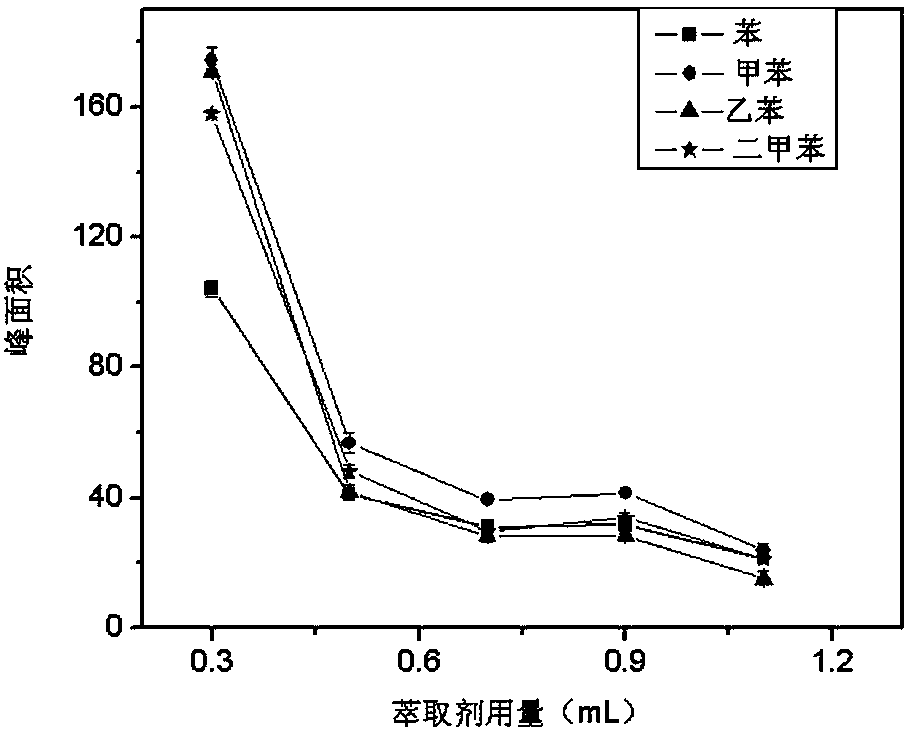

[0035] The optimization of extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com