Method for preparing prevulcanized hydrofining catalyst

A technology for hydrorefining and manufacturing methods, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of decreased dispersion, low activity recovery rate of regenerated catalysts, etc., and achieves good activity recovery. , No irritating odor, no pollution to the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

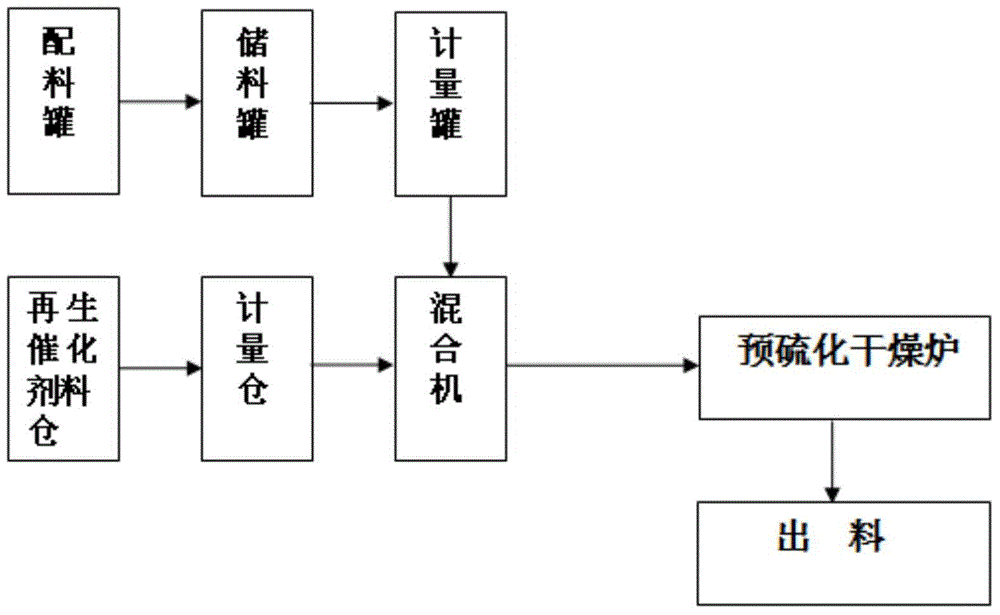

Method used

Image

Examples

Embodiment 1

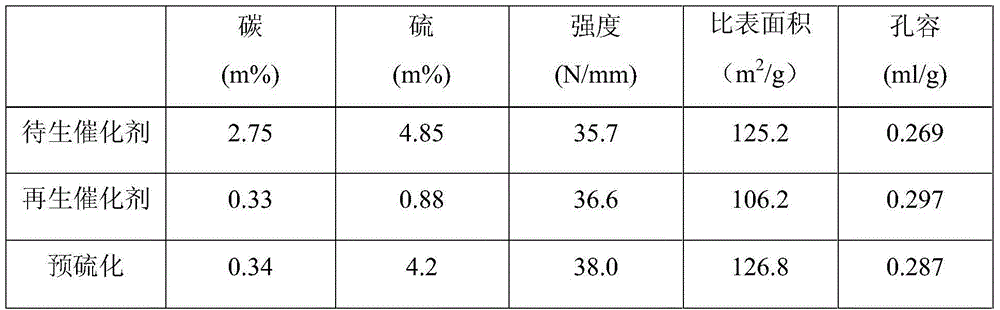

[0074] Example 1: KF-848 standby catalyst for production of presulfided hydrotreating catalyst

[0075] KF-848 is a catalyst prepared by STARS (Super Type II Active Reaction Sites) technology. This invention is used to regenerate and pre-vulcanize the old KF-848 agent with an oil content of ≤5%. Prepare a vulcanized oil additive according to Case 1. KF- The mass ratio of 848 regenerated catalyst and sulfurized oil additive is 100:14. The experimental data are shown in Table 2.

[0076] The experimental data that table 2KF-848 waits for living catalyst to do

[0077]

Embodiment 2

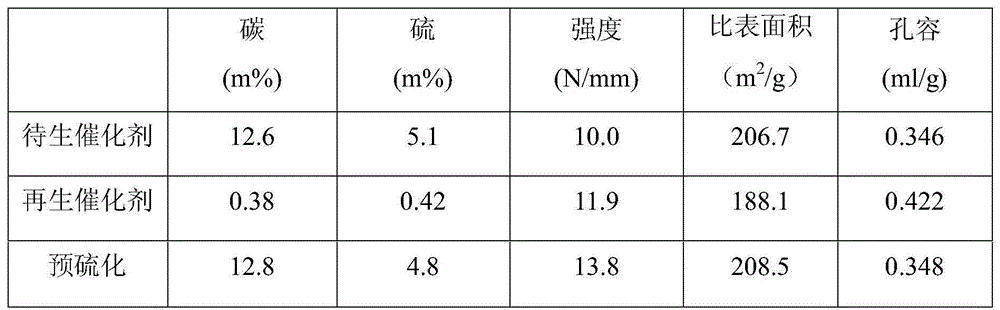

[0078] Example 2: Production of presulfided hydrofining catalyst with DC-2118 spent catalyst

[0079] DC-2118 is a catalyst prepared by Criterion Company of the United States using Cetinel technology. The invention is used to regenerate and pre-vulcanize the old DC-2118 agent with an oil content of ≤5%. Ratio of auxiliary agent DPTT to prepare vulcanized oil additive, the mass ratio of DC-2118 regenerated catalyst and sulfurized oil additive is 100:16.

[0080] Table 3DC-2118 experimental data done by the catalyst to be born

[0081]

[0082] As shown in Table 2 and Table 3, the active metal redispersion represented by the data is a qualified product after chemical treatment, and the experiment has achieved the expected effect.

[0083] The activity evaluation results of KF-848 and DC-2118 presulfided hydrofining catalysts of the present invention are shown in Table 4.

[0084] Table 4 Evaluation results of KF-848 and DC-2118 presulfided hydrotreating catalysts

[0085] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com