Method for presetting multilayer panel slot antenna brazing filler metal

A cracked antenna and brazing material technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of tediousness, distortion, deformation, etc., and achieve simple equipment and process equipment, simple preset process, and engineering application advantages obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

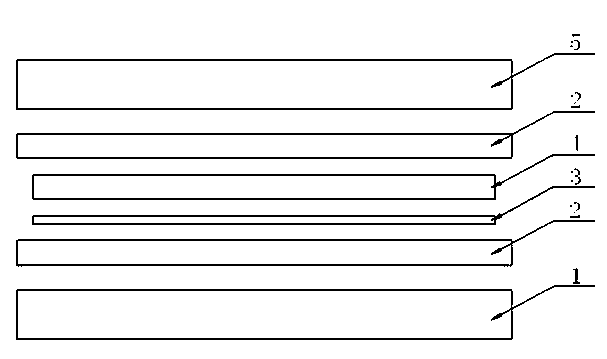

[0035] like figure 1 As shown, a multi-layer flat slot antenna brazing presetting method includes a substrate 1, heat-resistant glass or ceramics 2, brazing material 3, a finished flat slot antenna part 4 and a flat pressing plate 5.

[0036] The preset method of the multi-layer flat plate crack antenna brazing material comprises the following steps:

[0037] The first step is to clean the substrate 1, heat-resistant glass or ceramics 2, brazing filler metal 3, plate crack antenna part 4 and pressure plate 5 with an acid-base solution to clean oil, dust, metal deposits and other excess on the surface. After cleaning, the water traces on the surface of each component should be evenly distributed, and then put them in a drying oven for drying at a drying temperature of 110°C to 120°C and a holding time of 30±10°C.

[0038] The second step is to assemble the flat plate crack antenna parts and solder, the method is as follows:

[0039] a) Place the stainless steel substrate 1 on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com