Preparation method of multi-layer SiO2 inorganic anti-reflection film

An anti-reflection film, inorganic technology, applied in the field of preparation of multi-layer SiO2 inorganic anti-reflection film, to achieve good self-cleaning function, strong adhesion, reasonable preparation process effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

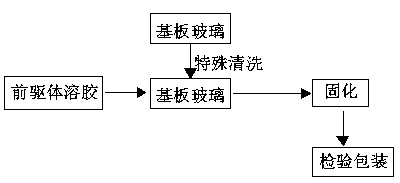

Image

Examples

Embodiment 1

[0030] (1) Substrate glass pre-treatment: Ultrasonic the substrate glass in acetone solution and ethanol solution for 30 minutes respectively;

[0031] (2) SiO 2 Preparation of sol: A) Acidic dilute SiO was prepared by traditional sol-gel method 2 The sol is used as the matrix solution; the typical preparation method is as follows: TEOS, ethanol and water are used as precursors, mixed according to the molar ratio of 1:30:4, added hydrochloric acid to adjust the pH to 2, stirred evenly, and aged at room temperature for 1 to 10 days That's it; B) Disperse the nano-silica powder in the ethanol solution, add a small amount of hydrochloric acid, and add a silane coupling agent for modification; then add the B solution to the A solution according to the ratio, the ratio is 1:2 , after stirring evenly, it can become a subsequent coating sol;

[0032] (3) Sol coating mold making: Coating on the surface of the glass substrate to form a thin film of 80nm;

[0033] (4) Film curing: T...

Embodiment 2

[0037] (1) Substrate glass pre-treatment: Ultrasonic the substrate glass in acetone solution and ethanol solution for 30 minutes respectively;

[0038] (2) SiO 2 Preparation of sol: A) Acidic dilute SiO was prepared by traditional sol-gel method 2 The sol is used as the matrix solution; the typical preparation method is as follows: TMOS, methanol and water are used as precursors, mixed according to the molar ratio of 1:30:4, added hydrochloric acid to adjust the pH to 5, stirred evenly, and aged at room temperature for 1 to 10 days That's it; B) Disperse the nano-silica powder in the ethanol solution, add a small amount of hydrochloric acid, and add a titanic acid coupling agent for modification; then add the B solution to the A solution according to the ratio, the ratio is 1: 10. After stirring evenly, it can become a subsequent coating sol;

[0039] (3) Sol coating molding: Coating on the surface of the glass substrate to form a thin film with a thickness of 80nm;

[0040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com